Pros and cons of using MDF panels for ceiling finishing

To achieve a good result, when choosing any material for finishing, you need to take into account its strengths and weaknesses.

Advantages of the material:

- Environmentally friendly. MDF panels are made from wood chips, which are hot pressed. No phenol or toxic resins are used for bonding, so the material does not emit harmful substances during operation.

- The panels can be used in premises for various purposes: office, industrial, residential.

- Large selection of colors and textures. You can choose a material that imitates wood or natural stone.

- Easy care: just wipe the ceiling periodically with a damp cloth.

- Easy to install, repair and replace, all work can be done with your own hands.

- Durability.

The disadvantages include the following features of MDF:

Like all wood-based materials, it is afraid of direct contact with water and steam, and can swell from dampness and become deformed. When washing, do not use household chemicals, this can damage the surface. Combustible material

The panels can easily catch fire if the fire is handled carelessly. For the same reason, it is necessary to carefully insulate all wiring.

Basics of installation work on finishing MDF ceilings photo

How to make a plastic ceiling with your own hands correctly, step-by-step process for installing plastic panels

The frame is prepared in advance before finishing the walls.

It is installed from a wooden beam 60 by 40 centimeters long and wide.

The timber prepared for the frame must be well dried. Raw material can lead to undesirable consequences, such as deformation or curvature of the ceiling.

Horizontal levels of the frame are marked on the walls using a water or laser level. In addition, it is necessary to use painting thread. When installing LED lighting, the frame level should be lowered 10-12 meters lower.

The timber is fastened along the horizons cut off on the walls with special elements called dowels.

The cord is pulled from two beams located opposite to each other. The interval between the bars should be no more than sixty centimeters.

Next, you need to secure the drywall along the cords and their length. At the next stage, the ceiling beam is secured with self-tapping screws. Thus, the frame is ready and you can safely carry out further work.

Next, the first panel is cut into two equal parts and applied with a tenon to the wall or frame. The panel is secured to the beams using self-tapping screws.

A distance of three millimeters is left in the space between the board and the wall, which will then be covered with the ceiling plinth.

The places reserved for self-tapping screws must be drilled with a drill. But only in such a way that the drill has a smaller diameter. Then the heads for the screws are countersinked.

The last of the panels is attached to the ceiling in the same way as the first, to the frame, and the finishing is completed by installing a plinth or corner.

Install MDF ceiling panels yourself and purchase them for your home! An ideal option that will transform your interior and also turn out to be a durable and practical companion!

In appearance and structure they are similar to conventional chipboard. Only now, there is still a difference between these two materials and it lies in the manufacturing technology.

When choosing a building material for a home that should transform the interior, not only its price and quality are important, but also many other advantages.

The advantages of the panels are more than enough, even if they have to be compared with other, more expensive ones.

So, the advantages of MDF panels for the ceiling are as follows:

- Easy to assemble material. You can assemble and install it on a ceiling or wall surface in just a few hours, without experiencing any particular difficulties.

- Working with panels is not dusty or dirty and will not cause inconvenience or discomfort.

- The coating disassembles quickly.

- An element damaged on the ceilings can be easily replaced.

- Caring for the panels is easy, even if they are laminated.

- It has a wide variety of textures and a wide price range.

- Resistant to any external influences.

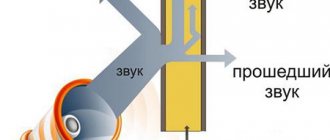

Thanks to the panels, the soundproofing of the walls in the apartment will not become its companion.

These and other advantages are a reason to make this material the main finishing material for the house, to use it for cladding both the ceiling surface and walls.

The panels have significantly fewer disadvantages than advantages.

Among the disadvantages of MDF for ceilings are:

- They have a low degree of water resistance, so as a result of flooding by neighbors or other penetration of moisture into the material, it can easily swell.

- Strength is not high enough. Any impact or other damage spoils its entire aesthetics.

- The panels are easily flammable. For this reason, you need to operate them in any room very carefully, making sure that no sparks fall on them.

It is easy to install it yourself without the help of craftsmen and enjoy the aesthetics for a long time!

Ceiling panels of this type are the best option for finishing at the most affordable prices!

What is MDF

MDF is a medium-density fiber-wood board used for making furniture and all kinds of interior decor attributes. MDF panels for ceilings are produced in the form of planks of different lengths and widths with special tenons on one side and carved recesses (grooves) on the other. The material differs from the chipboard we are all familiar with due to its special decorative coating, which gives it great strength, visual appeal and other valuable performance qualities.

Types of MDF panels

There are three main types of MDF panels.

- Painted. Covered with a durable layer of high-quality matte or glossy paint in various shades.

- Veneered. They have a natural veneer finish on the front surface.

- Laminated. They are decorated on the outside with a waterproof film made of modern polymer that imitates unusual designs, patterns, and the structure of natural wood or natural stone.

Popular types of MDF panels

General characteristics of MDF

The advantages of the material include unsurpassed strength and high flexibility, simple, convenient installation and ease of processing (it does not crumble when sawing). The widest range of shades and textures allows you to choose the right option for any interior solution, from elegant classics to catchy, extravagant modern or fashionable urban trends. High resistance to moisture (indicated on the packaging by a pattern with a drop of water) makes it possible to install MDF ceilings even in rooms with difficult conditions (kitchen, bathroom, etc.). Caring for the material (washing, cleaning) does not require significant effort and a lot of time.

The only significant drawback of the panels is their increased flammability, characteristic of wooden products.

Beautiful examples

Ceiling made of PVC plastic panels step by step instructions

MDF panels can be used in different rooms. To prevent such an addition to the interior from spoiling the overall picture, you need to use the ideas of real masters of their craft as an example.

Modern living room

A beautiful living room in a modern style is a triumph of minimalism and subdued tones. The background in this room is contrasting - part of the room is dark, while part, on the contrary, is very light. In the dark area, the ceiling and wall are finished with MDF panels of the same color. The material is stylized as parquet masonry, which looks very interesting. This background adds coziness to the room and sets the whole family and guests up for relaxation.

Textile products were also selected to match the color of the wood. These are not only checkered curtains, but also equally stylish pillows.

Classic interior

The second example is a beautiful living room in a classic style. It is made in light colors. The floor is dark, the walls are coffee, and the ceiling, made of MDF panels, is very light. The beautiful finishing around the edges reminds us of ancient houses in which the ceilings were decorated with stucco. And the lighting allows you to feel comfortable in any part of the room. In the center of the ceiling there is a luxurious chandelier, which serves as a real decoration of this room.

Against the background of such a light ceiling, furniture made several shades darker also looks good. This includes a sofa, armchairs, shelves, and everything you need for a comfortable stay in the company of loved ones.

Bright corner for relaxation

The last example is a room decorated in bright colors that serves as a place to relax or work. Colors that are too light are known to be relaxing. But the shade of yellow present here, on the contrary, will charge the person entering with energy. Both the wall, the ceiling, and the floor are in the same color, so the room does not seem too colorful. In addition, stylized wood inserts soften the white background of the wall.

The lack of wide windows next to the reading corner is compensated by good lighting. Along the entire perimeter of the ceiling there are neat chandeliers that provide pleasant light.

MDF panels are a good option for finishing a modern room

It doesn’t matter whether it’s a bedroom, a bathroom or a kitchen – with proper care, they will last a long time, regardless of where they are used. Take into account the manufacturer's recommendations for care, designers' advice when finishing, and then your interior will become unique and arouse the admiration of all guests who come to your home.

How to attach panels to the ceiling, see the video below.

Advantages and disadvantages of the solution

By deciding to make an MDF ceiling in your home, you will not only be able to easily hide even very significant flaws in the base surface, but also a lot of other advantages:

- It is possible to choose both the color and texture of the finished structure. The front side of more budget panels is decorated with films or painted, while more expensive options are covered with natural wood veneer.

- The frame structure of the ceiling implies the presence of some distance between the ceiling and the plane assembled from the panels. In this part of the composition you can place all the necessary wires or other technical communications.

- It will be possible to install recessed lamps in the ceiling and place them exactly where lighting is most needed.

- The heat and sound insulation of the room in which such a ceiling will be assembled will improve.

- No careful preparation of the base for work is required - just assemble the frame and attach the panels directly to it.

- The service life of the coating is many years without losing its beautiful appearance.

- Partial dismantling and repair of the coating is possible without completely dismantling the structure.

- Standard types of panels are inexpensive. Those covered with veneer will cost significantly more, but they look much better.

- The durability of the coating is quite high.

Such coatings also have several disadvantages. Most of them cannot be called too significant to give up the idea of decorating your ceiling with this material. However, you should know in advance about the possible disadvantages of the solution:

- Veneered coatings do not withstand moisture well and should not be used for finishing bathrooms or kitchens. An alternative for such rooms would be film-laminated parts.

- Laminated parts, in turn, are not recommended for children's rooms and bedrooms, since their surface is impermeable to air, and vapor permeability is important in these parts of the house.

- Due to the fact that MDF is based on wood, this material is very poorly resistant to fire and is potentially fire hazardous.

Base ceiling mounting

How to make a ceiling from PVC panels with your own hands

This method is considered simpler and lighter compared to suspended profiles. To attach to a base ceiling, there is no need to install additional structures, which means significant savings in financial resources and time. The advantage of this finish is the fact that when mounted on a base ceiling, the height of the room does not decrease. Decorating with this finishing method is quite varied, thanks to the available finishing materials. But it should be noted that this method does not allow the installation of shaped structures, as well as the installation of ventilation communications and lamps.

Panel installation

To install a ceiling made of MDF panels with your own hands, the homeowner will need the following tools:

- pencil and cord or thick thread rubbed with chalk;

- tape measure and level;

- a diagram of the location of electrical wiring on the ceiling or a device that detects it;

- miter box, metal scissors;

- a hammer drill and a screwdriver with an angle attachment (you can do without it);

- a drill with a crown, a circular saw with guides, a nail gun or a hammer;

- fastening elements: screws, nails, staples, dowel-nails.

The following materials are also purchased for attaching MDF panels to the ceiling:

- the panels themselves;

- ceiling plinths;

- wooden bars and metal holders;

- for metal lathing you will need connectors, hangers and guides for the profile, profile.

Ceiling technology

Before attaching the MDF, the home craftsman must mount the sheathing on the ceiling:

- determine the level at which the ceiling will be located, not forgetting the size of additional elements in it, for example, lamps;

- measure the dimensions of the ceiling, then mark it with a pencil and a chalk cord so that the ceiling is lined with squares with a side of 100 cm;

- using a wiring diagram or a special device to find it, mark the location of the wires on the ceiling;

- Use a puncher to make holes in the places where the marking lines intersect. If there is wiring at the desired point, move the drilling location a few centimeters so as not to catch the wiring with the drill;

- insert the dowels into the resulting holes and secure the hangers with dowel nails;

- slightly bend the edges of the hangers towards the ceiling;

- mount the guides for the profile using a level and making a hole for the dowel-nail;

- fasten the profile to the suspension on both sides with metal screws, controlling the process with a building level;

- bend the protruding edges of the suspension more strongly or cut off completely;

- install the second profile, aligned with the level of the first, the third - with the level of the second, and so on;

- to make a profile shorter, cut it with metal scissors, and to lengthen it, use profile connectors;

- take the last step before installing the MDF panels - fasten the wooden beams to the resulting frame in increments of 40 cm (it is advisable to calculate the exact step according to the size of the purchased panels) using a screwdriver and self-tapping screws, leaving a gap of about 5 cm between the outer beams and the wall so that it was hidden by baseboards.

A metal profile frame is preferable in terms of durability and fire resistance

After installing the sheathing, begin installing the MDF panels on the ceiling:

- attach the panel to the sheathing, insert a metal holder in those places where the panel meets the wooden beams of the sheathing, and nail it to the beams;

- install the staples on the first panel close to the edge so that they can be hidden by the baseboard;

- insert the next panel into the groove of the previous one, the third panel into the groove of the first, and so on until the end of the ceiling;

- if the edge panel does not fit into the remaining space, it needs to be cut: measure the empty space on the ceiling, measure on the panel and cut it;

- When installing MDF panels with your own hands, at the same time monitor the electrical wiring and cut holes for it with a crown drill;

- Installation of MDF plinth is carried out by coating it with glue and installing it in the desired place, followed by fixing it with nails without a head.

Practical techniques for attaching MDF panels to the ceiling are shown in the video:

https://youtube.com/watch?v=CrqfLr_FZj8

Installation of MDF panels on walls: step-by-step instructions

In order to install the panels efficiently, it is important to strictly follow the technological process, which in general is not particularly difficult

Surface preparation

No special training is required to work with MDF sheets. If we are talking about walls, it is enough to tear off the wallpaper and carefully prime the surface to prevent the formation of fungus.

If desired, you can cover the wall with insulation (for example, foil penofol).

Measurements

Any finishing requires accurate measurements. And the first thing you need to do is determine the height and width of the walls. The easiest way to calculate the amount of material is to draw up an exact layout of the elements on the wall.

Selecting a frame and its subsequent installation

Lathing for MDF panels can be of two types:

- from a metal profile for plasterboard;

- from wooden planks.

The last option will be slightly cheaper. But it is unlikely to be suitable for installation in a damp room, since wood is a material that does not have a high moisture resistance. The metal profile is stronger and more durable.

Fastening panels

You can attach MDF to the frame using glue, clamps (these are special brackets made of metal) or self-tapping screws. If adhesive is used, it is highly recommended to use moisture-resistant materials.

When working with self-tapping screws, the latter should be installed at a distance of 10 to 15 millimeters from the edge. This will be enough to successfully hide the screw heads under the baseboards or under the corners.

Why wall parts?

Many may ask this very question when they see the word “wall” in the title. The use of this kind of wall details is dictated by several points:

- The coating is much more durable.

- The thickness of the parts is greater and due to this, their heat-saving and sound-proofing characteristics are improved.

- The choice among various options for wall materials is often much greater than for ceiling coverings.

- Often stores simply do not have MDF boards for decorating ceilings.

All these nuances force us to choose coatings that would seem unsuitable for use as ceiling cladding. There are no other fundamental points in the use of such materials.

DIY ceiling made of MDF panels

To finish walls and ceilings with MDF panels you will need the following tools:

- building level

- pencil

- screwdriver, screwdriver

- for concrete surfaces – hammer drill

- wood hacksaw, jigsaw

- measuring device (roulette)

- metal scissors

From materials:

- self-tapping screws

- pendants

- profiles

- clamps

- dowels

- ceiling plinth

- connector

- finishing material

To finish the ceiling with MDF panels, you first need to make a frame. First, you need to make markings around the perimeter of the room, using a tapping cord, having first retreated 5 cm from the ceiling. In accordance with the drawn markings, the first profile will be attached. You can check the horizontality of the marked line using a building level.

The first profile is mounted on wooden surfaces with self-tapping screws, and on concrete surfaces with dowels; the distance between them should not exceed 50 cm.

You need to insert the ceiling profile into the guides. The step frequency should be 40-60 cm.

After that, ceiling suspensions are installed, to which the profiles are attached. The optimal distance between profiles along the length is up to 70 cm.

For information! The edges of a hanger that is too long can be directed upward or trimmed with metal scissors.

Each profile needs to be attached to the suspension on both sides; it is especially good to do this with self-tapping screws with a pointed tip. Next, the transverse profile is fixed and leveled.

There is an opinion that wooden blocks can be used instead of metal profiles. This option is quite possible, but not in rooms with high humidity, since there is a high probability of their deformation and damage. Working with wood material in dry rooms is simple and easy.

We begin to sheathe the frame with MDF panels. Panel fastening process:

- Cut strips of the required size using a jigsaw with a sharp blade;

- The first panel must be inserted into the guide profile and secured with self-tapping screws or clamps every 20-25 cm;

- The second panel is inserted and connected to the starting one. The tongue-and-groove technology is used; the tongue of the second panel must be inserted into the groove of the first;

- Each subsequent panel is mounted to the ceiling profiles. To avoid cracking of wood-fiber material, you can use clamps. Nails or screws are screwed into the installed plate;

- It is recommended to prepare places for built-in lighting fixtures immediately. To do this, first insert the panel, mark the specific location of the lamps, remove the finishing material and make a hole to size. For convenience, it is good to use a screwdriver with a special attachment - a crown. After the preparatory work, the lighting fixtures are installed and the panel is mounted on the working surface;

- The last panel often does not fit in width, and it has to be adjusted and trimmed.

The final stage is the installation of the ceiling plinth. It is needed not only to give the structure an attractive appearance, you can hide fasteners under it.

The ceiling covering with MDF panels is finished. All work on installing the finishing material can be done with your own hands, without the involvement of a construction team. This is an affordable and effective way to cover ceiling surfaces. And the use of panels with a three-dimensional texture will allow you to create an original interior in your living space.

MDF panel installation technology

Before starting finishing work, it is necessary to: prepare working tools, purchase the required number of panels and additional elements (see Ceiling plinth Format: information about the manufacturer, types of plinth, related products).

MDF ceiling panels

Necessary tool

We will need a tool that a home craftsman will probably have:

- Pencil.

- Building level.

- Roulette.

- Hammer.

- Metal scissors.

- Screwdriver.

From the materials we will need:

- MDF panels.

- Ceiling plinths.

- Galvanized metal profile.

- Suspensions.

- Connectors.

Veneered MDF panels for ceilings

Frame installation

- Let's move on directly to installation. First of all, we begin assembling the frame from metal profiles. Using a building level, we mark the perimeter of the room. In this case, the distance from the ceiling must be at least 5 cm. After marking, using a special device, we check the location of the hidden wiring.

- We fasten the starting profile around the entire perimeter of the room using dowels or self-tapping screws. It depends on the material of the walls. The fastening pitch is 400 millimeters.

- The next step is installing the ceiling profile. It is inserted into the starting profile parallel to one of the walls. The profile pitch is 400-600 millimeters.

- Next, we attach the ceiling profile to straight ceiling hangers. The profile is attached to the suspension on both sides with self-tapping screws.

For each subsequent profile, we take the horizontal level from the previous one, install all the remaining profiles identically, if necessary, shortening them using metal scissors (see Ceiling tiles made of polystyrene foam - select the appropriate option).

If the length of the profile is not enough, you can use special connectors to lengthen it.

- Installation of wooden blocks. It is with their help that MDF panels will be attached to the ceiling. We fasten using a screwdriver and self-tapping screws. When installing the edge bars, a prerequisite is a gap from the wall of approximately 5 centimeters. We carry out calculations individually for your existing ceiling plinth.

- Calculate the length from one bar to another, relying on the geometry of your specific MDF panels; as a rule, the distance between the bars is about 40 centimeters.

Thus, we prepared the ceiling directly for the installation of MDF panels.

Installation of MDF panels

Attaching MDF panels to the ceiling is very simple. To do this, it is enough to acquire special metal holders.

The installation algorithm looks like this:

- The panels are fastened using tongue-and-groove technology. Therefore, finishing the ceiling with MDF panels begins with securing the very first screws or nails. Then this fastener can be easily hidden using a ceiling plinth. The panel fastening spacing is no more than 200 millimeters (see Installation of ceiling plinth: expert advice).

Panel installation

- The next panel is inserted into the groove of the previous panel. We secure it from the groove side with a clamp.

A kleimer is a special fastening element that allows you to secure moldings and MDF panels to the walls and ceilings of a room.

It is a rectangular metal plate that has special cuts and a tongue with which the panels are actually attached (and screws are screwed into the cuts of the plate or nails are driven into them). Considering that the panels can be used in rooms with high humidity, the stamp is specially made in such a way that its anti-corrosion properties are maximized - it is made of carbon steel and additionally galvanized.

Fastening with a clamp

- If the panel is too long, it must be shortened. We do this using a jigsaw with a cutting blade designed for a clean cut.

Jigsaw

When installing panels, you should make holes for spotlights in advance using a “crown”.

This can be done on an already installed panel, or before its installation. We install sources of spot lighting in the resulting holes. When installing halogen bulbs, remember that they are very sensitive and should not be touched with your hands. All subsequent panels are installed in the same way.

- Lastly, the decorative plinth is installed. It will give our design a complete appearance. It will also help hide the starting fasteners.

Ceiling plinth option

This completes the finishing of the ceiling with MDF panels. We examined in detail all stages of installation work. They talked about all the subtleties and nuances. Now you should have no questions left.

Decorative MDF panels

MDF ceiling tiles are a modern finishing material. Unlike PVC, it has high levels of noise and heat insulation, as well as an excellent level of thermal protection.

Decorative MDF panels are also divided into two types:

- Laminated - the top layer is made of PVC film, which gives the material the ability to withstand moisture and water, as well as additional strength. The surface is easy to clean from dirt and is resistant to mechanical stress.

- Veneered - made from veneer of valuable wood species, which is obtained by peeling. In the manufacture of this material, any harmful phenolic resins are excluded. The surface of such plates is coated with special paints that are chemically resistant. This layer gives MDF panels high aesthetic properties and special strength.

Installation of decorative MDF boards

Ceiling tiles made of MDF must be mounted on a pre-installed wooden frame or metal profile. Also, before starting to decorate the surface, the following work is carried out:

- communications are laid and hidden;

- carry out insulation of the ceiling (if necessary);

- install ceiling lamps and fixtures.

Installing panels on the ceiling requires the presence of a frame. To do this, it is necessary to install the sheathing in increments of about 400 mm. Each individual frame element is mounted on the ceiling using self-tapping screws or dowels, as shown in the photo.

When the sheathing is completely installed, you can proceed to attaching the wooden panels. The first element of decorative finishing is mounted on the sheathing using self-tapping screws. All subsequent ones are fastened with clamps (special fasteners). In this way, MDF panels are installed over the entire area.

When choosing decorative materials, you should pay special attention to their surface. The top layer should not have any flaws

Low-quality PVC panels may have a blurred pattern, which can be easily removed with a regular damp sponge.

Also, numerous defects may be the result of improper storage conditions, which is especially common in markets. To minimize the risk, you should purchase finishing materials from construction stores, where all requirements regarding storage and transportation are met. In addition, if a defect is discovered, the product can be returned and your money back.

Pros and cons of the material

MDF panels have many advantages. In addition to the ease of installation, both on the wall and on the ceiling, which can be carried out both horizontally and vertically, these include the external beauty of the material, which is presented in a wide variety of colors and textures (see photo), the ease of maintenance for which is sufficient just a slightly damp cloth, and also a fairly affordable price.

But along with the advantages, like any other finishing material, MDF panels also have their disadvantages

These include the presence of free space between the sheathing and the wall, as a result of which, if handled carelessly, there is a risk of dents or cracks. Also, it will be difficult to hang shelves and pictures on an MDF surface.

To install them, you will need to use very long dowels, which must go directly into the concrete or brick surface.

MDF panels are materials with low fire resistance, so it is very undesirable to use them in the kitchen, bathroom and toilet, as well as in other rooms where open fire will be used or there will be excessive humidity. It is recommended to make a distance of approximately 45 centimeters between the individual elements of the sheathing during installation. If it is even a little larger, MDF structures on the walls and ceiling may “play,” which will sooner or later lead to their damage.

Preparatory work

In order to install MDF panels on the ceiling or walls with your own hands, you will need the following materials and tools:

- pencil;

- roulette;

- building level;

- metal corner;

- electric jigsaw;

- construction stapler and staples;

- screwdriver or screwdriver;

- self-tapping screws;

- drill.

It is not necessary to level the surface before installing the material.

In this case, it does not matter at all what material it is made of: concrete, bricks, wood or foam blocks, whether there is any finishing on it or not. It is enough just to apply several layers of primer mixture to the wall or ceiling, after which you can proceed to creating your own lathing

If wood will be used during the work, it must be covered with special mixtures that will protect it from moisture and insects. If necessary, insulation material, for example, mineral wool, can be laid between the profiles, which can be seen in the presented photo.

Installation technology

The process of installing MDF panels on the wall and on the ceiling is almost the same, with the only difference being that during installation on the ceiling you will need an assistant to hold the paneling. So, in order to cover a room with MDF panels you need to:

- choose the direction of installation of MDF structures;

- fix the lower profiles at a distance of 5 centimeters from the floor, and the upper ones - about 3 centimeters from the ceiling;

- make the distance between the profiles equal to 45 centimeters;

- use a building level to check how level the profiles are;

- attach additional profiles around window and door openings;

- if the MDF panels are positioned vertically, installation should begin from the left corner, gradually moving to the right, and if horizontally, from top to bottom;

- attach the sheathing to the sheathing using clamps, which are specially designed for working with such materials;

- attach the clamps to the profiles using self-tapping screws;

- installation of MDF panels is carried out using the tongue-and-groove technology;

- Cut the last sheathing element to the required dimensions and attach it to the sheathing using self-tapping screws.

After installing the material on the walls or ceiling, the corners of the room, both internal and external, must be covered with special corners made from the same fiberboards. The corners can be secured very simply with glue (see photo). They will serve more of an aesthetic function, hiding underneath the self-tapping screws that hold the trim along the edges. More detailed information on how to properly install the panels can be viewed in the video presented.

Preparatory work and installation of panels itself

Now about how to attach the panels to the ceiling. We will need to assemble a hanging frame onto which we will attach the panels themselves. To do this you will need the following materials:

- metal profile;

- baseboard;

- fastenings for suspended structures;

- pendants.

Tools that will be useful:

- perforator;

- level;

- roulette;

- screwdriver;

- marker;

- small metal scissors to help trim the profile.

The work sequence looks like this:

- First of all, we mark the area. We take a pencil or marker, arm ourselves with a level and mark a distance of 5 cm from the ceiling along the perimeter of the room. The lowest angle is taken as the starting point.

- According to the marks, we attach the starting profile to one level along the entire perimeter of the working area. The easiest way is to use self-tapping screws in increments of 400-450 mm as profile fastenings.

- A ceiling profile is mounted into the starting profile, and the fastening is the same screws.

- We drill holes at intervals of 600 mm from each other. We mount the hangers into dowels. We place the profile so that the resulting area is divided into squares or rectangles.

- The places where the profiles will intersect with each other are fastened with “crabs”. As a result, we get a metal frame with a good margin of safety.

- Now you can attach the MDF panels. To do this, we use clamps that are attached to the profiles. The clamps will create a visual seamless effect, so the ceiling will look very neat.

- The panels should be fastened so that there is a small gap between the edge of the material and the wall. Upon completion of installation, ceiling plinths should be installed to hide the side gaps.

A do-it-yourself ceiling made from MDF panels using a metal frame is ready.

MDF panels for ceilings

It comes as a simple paper plan, or with a surface laminated with film.

A simple MDF ceiling covering is used for cladding corridors, kitchens or living spaces in general.

You can decorate not only the ceiling, but also the walls with this material. The decoration will not only look aesthetically pleasing, but will also prove to be a practical companion to your interior. Finishing the ceiling with these panels is a simple process that does not require much time.

They can also be used to sheathe interior partitions.

The materials for the ceiling and walls have different structures, differing from each other in many ways.

The panels have the following advantages:

- High-quality and inexpensive (white or colored).

- Durable.

- A practical solution to interior problems.

- Aesthetic.

- The ceilings will provide sound insulation to the walls in the apartment.

If the room has tiles, then laminated MDF is suitable for finishing the ceilings and walls, which will look perfect on their surface.

The main stages of installing a false ceiling

Installation of suspended ceiling

Only with proper installation of a false ceiling can its main functions be performed.

Let's look at everything in detail:

- Stage 1 – marking the ceiling

Then hammer nails into the corners of the ceiling structure and stretch the twines between them. Thus, find the central part of the ceiling.

Ceiling markings

- Stage 2 – installation of a frame made of profiles. Based on the marks obtained on the wall, you need to install guide profiles. To do this, we apply marks through the mounting holes. In these places we make indentations with a hammer drill and insert plastic dowels.

Now we proceed to install the profiles and secure them into the prepared dowels with special self-tapping screws.

Installation of a frame for a false ceiling

Next, using self-tapping screws, we securely attach the ceiling profiles to the guide profiles (see Modern do-it-yourself ceilings: mirror and hemmed structures). In this case, you need to connect the profile guides to each other - to do this, install one profile into another, and securely fasten all connection points with self-tapping screws. We completed the installation of the frame. Now you need to think about how to conduct all communications: telephone and television cables, electrical wires, ventilation.

- Installation of plasterboard sheets.

With the help of a partner, the first sheet of drywall is lifted to the ceiling and attached to the metal frame using self-tapping screws. What’s interesting: you can start laying the sheet from any angle. Initially, we make the fastening along the perimeter of the plasterboard sheet, and after that - along those ceiling profiles that remain under it. Drywall is easy to cut, so if necessary, we cut it according to the required dimensions (see Lining the ceiling with plasterboard: instructions). Gradually close the entire ceiling. Don't forget that you need to leave holes for attaching lamps.

Installation of drywall sheets

- Primer and putty of all joints and seams. After completing the installation of all sheets of drywall into a single ceiling surface, we begin to putty the seams and joints.

After these procedures, we once again putty the seams and joints, prime them and sand them, prepare the ceiling for painting with water-based paints - this will give it a snow-white appearance. If desired, the finished ceiling can be finished with a ceiling plinth, giving the entire ceiling structure a complete look.

As you can see, it is quite possible to install suspended ceiling structures yourself

It is important to have a reliable friend and listen to the advice of experts. And then the false ceiling will delight you for a long time

Mounting methods

For fixation to the sheathing, you can use construction staples (in case of installation on a wooden beam and using a construction stapler), nails or self-tapping screws

Please note that in the latter case, you need to countersink each “breakdown” (make a recess for the head). Methods of fixing to the ceiling depend on the density of the sheet

We remember that the denser the fiberboard sheet, the heavier it is, and, accordingly, the stronger the materials for fastening. Protruding iron from staples or nails must be carefully puttied, because over time these iron parts will rust and show through the paint or wallpaper.

Ceiling made of PVC panels

Recently, plastic as a material for finishing ceilings in the kitchen is being remembered less and less. Although it is quite durable and interacts well with a permanently humid environment.

There are options with a modified mirror surface.

True, this all applies only to the more expensive segment: the most affordable options for plastic panels look frankly cheap, and from the point of view of environmental safety they are completely inferior to the alternatives described above.

Pros:

- cheap and cheerful;

- quick installation.

Minuses:

- turn yellow over time;

- Sometimes there may be an unpleasant smell of plastic;

- Careful care is required to extend service life and maintain appearance.

Perhaps for the kitchen it is worth paying attention to the slatted ceiling.

It consists of a large number of narrow panels and can be either strictly plastic or aluminum. The latter option is several times more expensive, but it is much easier to care for.

MDF panels and lining

If you use wood and its derivatives to decorate the ceiling in the kitchen, then only after additional treatment of the material with an antiseptic and careful varnishing. This will prevent moisture from entering the joints and preserve the service life of such a structure.

In addition, such ceilings can be installed only in those rooms where air humidity does not exceed 70% level.

Pros:

- the tree is always beautiful;

- environmentally friendly.

Minuses:

- life time;

- massive construction;

- a narrow range of suitable interior combinations;

- flammability;

- low moisture resistance even after impregnation.