Nowadays, the building materials market is so diverse that everyone will find what they need, both in quality and price. One of the most used materials in construction is sealant. With its help, you can protect the joints between materials from moisture, as well as eliminate some defects. The only problem with the sealant is the difficulty in removing it from the tube without a special tool. In this article we will tell you how to use a caulk gun. Using this tool will increase your work speed and make it more enjoyable.

Design and principle of operation

Regardless of what type of pistol, the basic structure is the same for all. It has a body, a rod, with the help of which the sealant is squeezed out, a trigger and a latch that holds the rod. The task of the work is to squeeze the contents out of the package. This process is very simple: you pull the trigger, which, in turn, sets the rod in motion. Next, the rod is pressed onto the bottom of the sealant package, which serves as a piston, and it comes out with ease.

Types and classification of pistols

Sealant guns are divided according to several parameters: appearance, complexity of the body structure, method of supplying the sealant.

| By design features | |

| Semi-hulled - they are not designed for long-term use. Such guns are suitable for small household work, are not very durable in use and are relatively inexpensive. | |

| Skeleton pistols, like half-body pistols, can cope with the same amount of work. They differ from each other in that the skeleton pistol is more convenient to use. It consists of two ribs and a rod, which allows the tube with sealant to be more firmly fixed in it, resulting in better quality of work. The cost of a skeleton pistol is higher than that of a half-body pistol, but it will also last longer. | |

| Case pistols are intended for those who do repair or construction work quite often. They are distinguished by their versatility; they can be used both for sealant in hard tubes and for sealant in soft packaging. Their cost is higher than all others, but due to the fact that the consumption of sealant with a housing gun is minimal, it is considered more profitable. | |

| According to the method of applying sealant | |

| Mechanical is the most affordable option. The supply of sealant in such guns occurs only due to the physical strength of the hands. Mechanical pistols are purchased for small household purposes. | |

| Pneumatic - used for medium-sized work. The principle of its operation is such that the sealant is released due to the pressure of compressed air. This type of gun has a special valve that allows you to discharge excess sealant and minimize its losses. | |

| Electric - allows you to make a more even seam and reduce the time required to complete the work. But to use them, appropriate experience is required. In addition, the cost of such a pistol, compared to mechanical and pneumatic ones, is much higher. | |

When choosing which pistol to buy, you need to consider how often you plan to use it and what your financial capabilities are.

Features and types

Such a gun cannot be called a complex device - in fact, it is a design for squeezing a sealing compound out of the container in which it is located. However, there are nuances in any matter, even in such a seemingly simple one. And based on these nuances, manufacturers offer tools for every wallet and for any purpose. Sealant guns can be divided into several categories according to the type of cartridge compartments, the features of the device and the method of supplying the sealant.

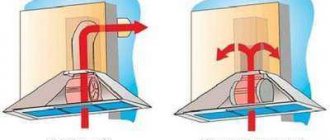

So, according to the type of compartments for cartridges (containers with sealant), these “peaceful” pistols can be divided into frame and sheet. The first ones are very popular among consumers because they hold the cartridge more tightly. Depending on the extrusion method, you will find cordless, pneumatic, electric and mechanical tools in stores. Each of them has its own advantages and disadvantages, so you need to choose depending on your goals.

What's good about cordless pistols is their autonomy - from the name it is clear that they operate from a battery pack, most often a lithium-ion one. Using a sensitive handle, the material is extruded, while the extrusion speed and feed accuracy can be adjusted using the same handle - the stronger the pressure, the more intense the work.

An electric gun differs from its battery-powered counterpart by and large only in the absence of a battery - the device runs on mains power. They apply sealant quickly and accurately, with a high degree of economy. Most often, these guns are used by construction professionals, because, in addition to convenience and autonomy, such pistols work with different types of cartridges. It is clear that such pleasure is not cheap, and for ordinary home use, for example, a small renovation in the bathroom, it is simply not advisable to buy this type.

Due to air pressure, a pneumatic type gun extrudes the material by pressing the handle. The design of such tools is often very ergonomic; manufacturers equip the tools with various stops and regulators, thanks to which you can obtain an even strip of sealant of the required thickness. Another good thing about the tool is the ability to work with different containers. It is advisable to use this type in medium and small construction, when the speed of work is not so important.

The most affordable and short-lived type of sealant guns is mechanical or manual. If we talk about everyday use, when you need to squeeze out 1-2 cartridges of material, this option is the most practical. But it will be difficult to work on large objects with such a tool, since squeezing out the mass is possible due to the physical effort of the hands, which reduces the accuracy and speed of work.

According to their design, pistols are divided into skeletal, semi-body and tubular. Skeletal ones are adapted for 310 ml cartridges. Semi-body instruments also work only with this volume, but have a simpler mechanism. Do not expect a long service life for such a tool - it is enough for 2-3 cartridges. And it will be quite uncomfortable to work with it - the rod squeezing out the mixture is quite tight, and besides, the tool tends to slip out of your hands every now and then.

It’s better to buy skeleton pistols - they are not much more expensive, but much more durable. The tubular type is capable of working with completely different cartridges, volumes from 600 to 1600 ml. Undoubtedly, such a tool will have to be refueled much less often.

Directions for use: instructions

Regardless of which type of caulk gun you choose, the instructions for use are similar for all. So, how to properly prepare a pistol for use? Let's look at each stage in turn:

- Using a stationery knife, carefully cut off the spout of the tube at an angle of approximately 45°. The width of the hole should be selected depending on the width of the intended seam.

- Having unscrewed the plastic cap with the cut off spout, pierce the protective valve on the package, and then screw the cap back along the thread.

- In order to insert the sealant package into the gun, you need to free up its internal space. By pressing the latch, push the rod back until it stops.

- The tube with sealant is installed into the gun body until it stops. The piston is pushed in until it comes into contact with the bottom of the package.

- To supply the sealant, pull the trigger of the gun. The speed of the extruded composition depends on the force of pressing.

When using sealant in soft packaging, only case guns are selected. The usage diagram is simple:

- Unscrew the applicator with the spout on the front end of the gun.

- Free up space in the gun in the same way as when using sealants in a tube.

- Using wire cutters, carefully cut off the metal bracket on one side of the package.

- Insert the package so that the cut end is in front.

- Screw the applicator back.

Video: how to insert sealant into a skeleton gun

Video: features of using a frame pistol

There are several rules for using a sealant gun:

- Before applying the sealant, it is necessary to thoroughly clean the area where it is applied: remove dirt, remove dust and degrease with alcohol.

- You can stick masking tape on both sides of the gap. Its function is such that when applying sealant, all excess will fall on it and you will not have to wipe off the excess. Peel off the tape immediately after finishing work. The seams are clean and even.

- For good and durable adhesion of the sealant, the surface is treated with an acrylic primer.

After finishing the work, the spout of the package is cleaned of any remaining sealant and closed with a special cap. This will protect the sealant from drying out. The sealant can remain closed for about three months without losing its qualities. The gun itself is also wiped. If this is not done, the gun can quickly become unusable. The metal case is cleaned with a special metal solvent. Plastic surfaces are wiped with soapy water.

Do not forget to ventilate the room well where you are carrying out repair work.

Video: How to Optimize a Casing Gun for Sealant

If during the repair you need to seal several cracks or joints, you can carry out these actions yourself using sealant. As everyone knows, sealant is mostly sold in packages with a long spout, but it is impossible to get the mass out of there without a special construction gun.

Seeing such a gun for the first time, not everyone will understand how to use it. But this article will tell you in detail and show that this unit is not so difficult to use, but it simplifies the repair process much.

How to choose the right option

When going to the store for sealant, you need to familiarize yourself with the assortment at home through online stores. There you can also read reviews about long-known manufacturers and completely new ones. Popular brands include:

- Moment.

- Penosil.

- Tytan.

- Ceresit.

We suggest you familiarize yourself with How to remove pomegranate from fabric

These manufacturers offer packages of different sizes. In addition, a coloring agent is added to the main composition, which allows you to select a sealing material that is invisible on any surface.

Advice! For home work, it is better to buy 2-3 small tubes of sealant than 1 large one. In a large open container, the substance quickly becomes unusable.

Some options have additional components that help resist silicone sealant to various microorganisms and fungi. Such compositions are called sanitary sealants. They are best used in rooms with high humidity.

When choosing, you must also remember that the composition can be:

- Acidic - acetic acid is added to the composition, because the substance has a pungent and unpleasant odor. This sealant cannot be used on metal surfaces as they are exposed to acid and will quickly rust. The putty is suitable for working with wooden and ceramic surfaces.

- Neutral. This option is universal and does not harm any known substances.

Attention! Additional components in the composition should be less than 10%. A higher value worsens the properties of the sealant.

There is currently a wide range of different sealants on the market.

Types of sealant guns

A construction gun is a device for effectively squeezing out sealant and has a not particularly complex design. But it would seem that such a simple thing is divided into types in accordance with the type of compartments for sealant, the structural features and supply of the composition.

According to the first criterion, devices are divided into sheet and frame. The second type is more common, as it has better and more reliable retention of the cartridge. Based on the method of supplying sealant, battery-powered, electric and mechanical units can be distinguished. Each type has pros and cons, so we can’t help but say:

Based on their design, devices can be divided into skeletal, tubular and semi-hulled. The first type is designed to work with 310 ml cartridges. Half-body versions of pistols are not very durable and are inconvenient to use. They also use 310 ml cartridges. The tubular type gun is suitable for professional work. It needs to be refilled less often, since absolutely any cartridge options are suitable for it.

Types and features of the device

According to the principle of operation, the gun for supplying sealant resembles a medical syringe, in which a thick mass is squeezed out through a hole in the tip using a rod with a piston.

Based on the type of device, these devices can be divided into three classes:

- Skeletal. The simplest and most inexpensive model designed to work with ready-made tubes. For the manufacture of this type of device, durable steel is used, therefore, despite its apparent fragility, the structure can last for quite a long time.

Semi-hulled. In these construction tools, the lower part of the cylinder is closed, which allows you to securely hold the tube. Half-body pistols are durable and easy to use.

Closed tubular. The closed tubular device is filled with the mixture prepared immediately before use. Such a device is usually found in professional models powered by a battery or mains power.

In addition, guns differ in the method of squeezing out the sealing mixture. Each type of tool has its own pros and cons that must be taken into account when choosing.

- Rechargeable. The device operates from an autonomous current source (battery). It is used extremely rarely in everyday life, as it is expensive and requires special training from the employee. The gun can be refilled either with ready-made tubes or with a mixture diluted from dry packaging. The design provides the ability to pre-set the mixture supply power.

- Electrical. The device operates from the electrical network. With this tool, sealant is applied quickly, accurately and economically. Recommended for professional use.

- Pneumatic. It is most popular because it does not require special skills or physical effort, is easy to use and inexpensive. The device squeezes out the sealing mixture using air pressure created by pressing the handle. The ergonomic design is equipped with all kinds of limiters and regulators for uniform supply of sealant. Used in cases where speed is not too important.

- Mechanical. A hand gun is the most affordable and short-lived; it is used when you need to quickly seal a leaking seam on a pipe or apply sealant between the tiles in the bathroom. The mixture is squeezed out using physical force of the hands, which negatively affects the speed and quality of work.

Which tool to choose, everyone decides independently, depending on the volume of repair work, the specifics of the sealing material and financial capabilities. If you need to seal two or three seams, you can get by with a cheap skeletal device. When work requires precision and speed, you cannot do without an electric gun.

Working with a pistol

Using a caulking gun is not difficult. Having familiarized yourself with the main nuances, you can safely get to work and be confident in a clear result.

The operating principle of such a device is not at all complicated. The gun works by applying pressure to a tube of sealant. As a result of this effect, a strip of material comes out of the container, which is mechanically aligned and placed in the right place. The pressure comes from a rod that is driven by a trigger. The main problems occur before the sealant is inserted into the gun.

Important! A pneumatic tool uses air instead of a rod.

Algorithm for using the tool

- Remove the restraints. When working with a skeleton or half-body caulking gun, there will be no problems with removing the stops. In addition to removing the limiting elements on the tool itself, you need to remove them on the container itself with the composition, if there are any on it.

- Pull out the rod. To move the rod, you need to press the lever all the way and pull out the rod. This frees up space into which a container with sealant is installed. Afterwards you need to press the trigger a few more times so that the tube is firmly secured.

- Release the sealant. We cut a hole in the cartridge itself that will allow the composition to pass to the nozzle. Usually the nozzles come in one piece, so it is also necessary to cut off the top part to create a hole of the same diameter as the thickness of the seam needed.

If a tubular or syringe type gun is used, the filling algorithm is slightly different. First of all, in this case, a hole is made in the container with the compound and its cut side is laid towards the hole through which the sealant will come out.

Important! Before inserting the container with sealant, the rod is removed. This is done in the same way as in the previous case.

As a rule, a set of tips is included with the gun. If the selected nozzle does not have a hole for the sealant to exit, you can make one by cutting off a small part of the tip. This should be done at an angle of 45 degrees.

Each individual caulk gun can be equipped with additional functions and certain elements that help during operation. That is why it is a good idea to study the instructions that come with the purchased pistol model.

Main advantages

In order to make joints between sewer pipes, sealant must be used between the wall and the bathtub or sink. The range of building materials offers several options for sealants based on different polymers. Suitable for use in bathrooms:

- Silicone.

- Acrylic.

- Silicone-acrylic.

- Polyurethane.

Silicone-based sealant is the most suitable option, which will help firmly bond the surfaces. It is different:

- Resistant to temperature changes. Manufacturers indicate the limits within which the substance fully retains its properties, this is from -50 to 200 degrees Celsius.

- Excellent adhesion. It adheres well to all materials used to furnish a bathroom (tile, metal, acrylic, wood, glass).

- Duration of operation.

Silicone-based sealant has excellent adhesion and resistance to temperature differences

But you need to remember that such sealant is more expensive than others. Although you shouldn’t skimp on creating a safe bathroom.

Sealant gun operating instructions

First, a little advice. If at the right time the gun is suddenly not at hand, then in order to knock the sealant out of the cartridge, you can use any available tool. For example, a hammer.

To use the gun successfully, follow these steps, which we have illustrated with pictures.

Step 1. First, take care of personal protection - at a minimum, wear gloves.

Step 2. Next, prepare the surface to apply sealant. In this case, we cannot advise anything specific, since everything depends on the instructions of the cartridge manufacturer. Everything should be written on the back of the latter. To remove the previous coating, use a sharp knife or triangular scraper. Remove remaining crumbs with a brush or use a vacuum cleaner.

In addition, the working surface must be degreased.

Step 3: Next, remove the limiters. If we are talking about a half-body or skeleton pistol, then this procedure will happen quickly. First, make sure that the tube does not have a special bottom-limiter. And if it is still present, then remove it.

Step 4. Let's figure out further how to use a sealant gun. Then pull out the rod in the device. To do this, press the lever and remove the part. Place the cartridge in the place that was vacated by the rod and apply a few gentle pressures on the hook to finally strengthen the container.

Installing a cartridge in a skeleton sealant gun (photo)

Note! In most cases, such cones come sealed. And if you also have it sealed, you will have to cut off the end of the cone to form the required seam diameter. It is important that the cut dimensions are smaller than required for the job.

But if you decide to use a tubular or syringe tool for work, then you should use it slightly differently.

Installing a cartridge into a tubular (syringe) gun for sealant

Photo - diagram of a tubular gun

Step 1: First, make a hole in the sealant tube. If you are using packaged material or a “sausage”, then cut off one corner/end with extreme care so that the mixture can easily come out of the bag.

Step 2. Next, place the prepared container with the material into the tool itself, but so that it is the cut end of the container that goes to the tip, through which, in fact, the strip of material will be squeezed out.

Step 3. Of course, before this you need to remove the rod - do this in the same way as with a skeletal-type device.

Step 4. Guns are often equipped with several nozzles with such tips. Choose one of them and screw it onto the cylinder. If you notice that there is no hole on it (the tip), then take a utility knife and cut the tip, but strictly at an angle of 45 degrees. Of course, you also have to guess the size of the future hole in order to get a seam of the required diameter.

Be that as it may, if you have a sealant gun on your hands, then you must also have the manufacturer’s instructions. Take the time to familiarize yourself with it, since manufacturers often equip tools with some improvements and developments that are not provided in standard models.

Video - Sealant application technology

As we have already found out, if the tool is properly equipped, then there should be no difficulties with its operation. And if you installed the cartridge as described in the instructions above, then you have already done half the work. Therefore, all that remains is to slowly press the trigger and apply the mixture to the desired seam. If you have a semi-body or skeletal type tool, it may take a couple of initial clicks for the required amount of material to fill the void in the tip. After this, make only smooth movements.

And if the model is battery-powered or electric, then by pressing the trigger you will regulate the intensity of the material supply. Therefore, if you are picking up a tool for the first time, then first practice in inconspicuous places - for example, seal a seam in the far corner of the room. After a little practice, you can move on to more visible places.

If you need to trim something or insert material into a gap, wet your fingers a little and run them along the surface. Use soapy water for this so that the mixture does not stick to your fingers. By the way, it is with this water that it is most convenient to remove the formed drips.

Note! The sealant does not require additional drying - in the fresh air it will acquire the required strength in just two to three hours.

And one more good tip: after you finish sealing, be sure to rinse the instrument with warm water.

Go ahead. To make the seam beautiful, use masking tape - stick it on both sides of the gap and remove it immediately after applying the sealant. To make a beautiful and, more importantly, high-quality corner seam, do the following. First, gently wet the side surfaces with soapy water. First prepare a small stick made of plastic or wood; Cut one side of the stick so that you can use it to set the shape for the seam. Accordingly, the final shape of the upper part of the seam will no longer be formed by the tip of the gun, but by the stick mentioned above.

Note! If you accidentally squeeze out too much sealant, don't worry - there's nothing wrong with it. Simply dry the seam with a hairdryer and remove the remaining material from the side surface using the same stick dipped in soapy water.

Gun for sealants. Types and device. Work and how to choose

A sealant gun is a specialized tool that works on the principle of a syringe, designed for squeezing sealants and adhesives out of a plastic or foil tube.

Purpose of sealant guns

Pistols are included in the basic tool kit of builders, carpenters, plumbers, and auto mechanics. The gun is used to work with sealants, liquid nails, various assembly adhesives, and sealants.

Guns are used to squeeze out sanitary silicone when sealing plumbing fixtures. They are used to glue ceiling and floor plinths. The tool is used for grouting tile joints, sealing joints between pieces of linoleum and solving dozens of other problems.

Types of guns by drive type

Depending on the source of force generated for squeezing out the sealant, guns are:

- Manual mechanical.

- Electrical.

- Pneumatic.

Manual mechanical ones are the most common and budget ones. They are equipped with a lever, during the reciprocating movements of which the rod squeezes the composition out of the tube. The advantages of such devices are comparative cheapness, as well as complete independence from electricity. They are light and silent. However, when performing large volumes of work, mechanical guns cause severe hand fatigue, which makes them inconvenient for professional builders.

Electric and pneumatic guns are professional tools, the use of which allows you to achieve the greatest productivity. Electric can be mains or battery powered. It is quite bulky and heavy, but it squeezes out the sealant quickly. The feed speed can be precisely adjusted, which distinguishes power tools from hand tools.

The pneumatic sealant gun is connected to the compressor. This significantly limits its range of action, which depends on the length of the hose. The use of such a gun is accompanied by noise from the compressor, which makes it a poor solution for most tasks. However, such a tool is more than suitable for use in production, for example, applying sealants in the manufacture of boat hulls, aquariums, and in the automotive industry. Often, air guns have a pressure regulator, which allows you to adjust the flow rate.

How to use a hand gun

A tube of glue or sealant is inserted into the body of the gun. Before this, the tip is cut off and the spout included in the kit is screwed onto it. Depending on the specific application of the sealant, the spout can be cut at an angle of 45 or 90 degrees.

Then, by reciprocating the lever of the gun, you need to set its rod in motion, which performs the function of a piston squeezing out the sealant. By pressing the lever at a certain speed, you can make a rough adjustment of the feed.

After finishing the work, you need to press a special foot on the back of the gun, which is responsible for the movements of the rod. When pressed, it unlocks and can be pulled back to release the tube.

Types of household pistols

To solve most problems, manual mechanical guns are used. They are also in demand by professional builders. The use of electrical and pneumatic devices is advisable only in large-scale production, or, for example, for sealing seams on the facades of panel houses.

A manual sealant gun may have the following structure:

- Skeletal.

- Strengthened skeletal.

- Half-hull.

- With a cylindrical body.

Skeleton pistol

The cheapest pistols are usually the skeleton type. They are more preferable for one-time work using sealants in a plastic tube. The actual resource of such a tool can often be only a few tubes. It consists of a handle with a rod and a stop, which is held by two posts.

The handle with the lever and the stands are made of very thin sheet steel with a cross-section of 1-2 mm. The rod itself is made from a rod with a cross section of 5-7 mm. At the edge it is equipped with a plate. As a result, when the lever is squeezed, it may bend due to resistance. The metal parts of the gun simply crack and it quickly becomes unusable. Moreover, if you use fresh sealants, the tool works quite well. When the composition in the tube dries out and is blocked by a stopper, the gun is not able to create enough force to squeeze it out, so it breaks.

Reinforced skeleton type sealant gun

It has a similar structure, but is made of thicker and stronger steel. A rod with a thickness of at least 8 mm is placed on it. It is made of hard metal, so the notches on it do not wear out when captured by the drive mechanism.

The tube support stands are made of sheet steel with a cross section of 3-4 mm. Sometimes you can find pistols in which the stands are made of the same rod as the rod. The reinforced tool is able to withstand almost any pressure on the lever necessary to squeeze out plugs from sealant frozen in a tube.

Half body pistol

This is the least successful technical solution. Such a gun, instead of two racks for attaching the stop, has a pipe cut lengthwise. It is also designed to accept sealants in a plastic tube. Such devices have 2 drawbacks: they are made of thin 1 mm steel, and their stem is often skewed.

When working with a half-body pistol, there is a risk of not only bending the thin lever, but also the tube itself that holds the stop. Under pressure, it often warps, which requires support. A half-body instrument is often more expensive than a regular skeletal one, since it takes more metal to make it, but objectively it is worse. This gun is only suitable if you need to use the sealant only once.

With cylindrical body

This is a universal sealant gun. Its peculiarity lies in the ability to work with sealants in hard plastic and soft foil tubes. In addition, they can be filled with various adhesives and other mixtures without packaging. A pipe is used as the body of such a pistol. It is removable, which allows for cleaning and washing in case of contact with the working composition on its walls.

When using a tool with conventional plastic tubes, it is disassembled and a steel plate is installed on its rod. After this, the body is screwed back on, the tube is lowered into it and it is closed with a plastic nut with a hole through which the spout passes.

When using a gun with a soft foil sausage tube, a wide plastic plate is installed on the rod. Then the body is screwed on and a soft tube with a cut edge is lowered into it. A nut with a spout that comes with the gun is installed on the body. When used this way, the spout needs to be cleaned after use. Also a disadvantage is the high risk of unused sealant drying out if you remove its remains from the gun.

You can also use a sealant gun in a casing to work with putties, adhesives, tile fugue and other materials that do not have packaging. To do this, a wide rubber piston plate is installed on the rod. The required solution is placed into the pipe with a spatula or simply sucked into a syringe. Next, the gun body is closed with a lid with a spout. After using the tool in this way, do not leave it refilled. After use, it requires cleaning and washing.

A common problem with body guns is that sealant gets through the plate into the pipe. This problem occurs with a budget tool. You can solve this by changing the plate to a more suitable diameter. A similar piston can be purchased separately at a specialized store.

How to determine if a pistol is quality

On sale you can find a sealant gun for every taste and price. There are both frankly expensive tools and very cheap ones. In this regard, it becomes difficult to choose a pistol of sufficient quality that will not break during operation. First of all, it should not be made of thin metal. The more massive the instrument, the better.

If a gun is needed for frequent use, then in addition to its strength characteristics, ease of use is also important. In this regard, when choosing, you can be guided by its compliance with several parameters:

- Type of the back side of the rod.

- The presence of automatic reverse when releasing the lever.

- Has a quick pressure release button.

The back side of the rod may have a convenient butt or simply be slightly curved. The presence of the first allows you to grab it with convenience and pull it out of the tube. A complete backplate is important in cases where the sealant has penetrated to the plate and stuck to it, preventing the rod from returning. In this case, the stop allows you to comfortably grab the piston.

It is desirable that the sealant gun automatically returns the rod a few millimeters when the lever is released. This will allow you to reduce the pressure in the tube during pauses between jobs so that the sealant does not squeeze out on its own. Many devices have an additional lever or button that, when pressed, releases the rod to release the pressure. This makes it possible to more reliably prevent leakage of sealant during breaks in work.

Basic classifications

Based on the type of compartments for cartridges (that is, containers with the mixture), the tool is divided into two categories:

- leafy;

- framed

The latter are more popular because they fix the cartridge more securely. Depending on the method of squeezing out the mixture, guns are divided into four more categories.

Finally, according to the design features, pistols can be:

- skeletal (designed for cartridges with a volume of 310 milliliters);

- half-body (the volume is the same, but the mechanism is simpler; designed for several cartridges, but extremely inconvenient to use);

- tubular, working with any cartridges.

Note! The best option is a skeleton pistol. It costs a little more, but is more durable.

But how to choose the right option? Let's get a look.

Device capacity

The capacity is affected by the size of the chamber installed in the air gun. A certain device contains a different volume of sealant.

This feature is part of the design provided by the manufacturer for filling the device with sealant more rarely.

Most often, cylinders with a capacity of 500 ml are suitable. – 1.5 l.

Features of choosing a sealant gun

The most important criterion is the amount of future work. If you only need to process a couple of joints, you can safely purchase a skeletal tool. And if you have a more complex task ahead (such as, for example, repairing an entire home), then buy a tubular-type pneumatic tool.

When only accuracy and speed of work are important, the best option is a battery-powered or mains-powered tool. Directly at the time of purchase, see how convenient the gun is for you personally, and whether the elements will interfere with operation.

And pay special attention to the hook itself: see if it is fixed tightly enough, what it was made of, etc. Finally, if we talk about specific brands, then, of course, give preference only to trusted manufacturers who have already earned trust.

As you can see, there is nothing complicated about how to use a sealant gun. All you need is the right tool, a quality mixture, a little practice and, of course, good step-by-step instructions. You have already found the last one - here - so all that remains is to go to the store to buy it.

And finally, another useful video. Good luck with your work!

Video - Using acrylic sealant

Reading time ≈ 3 minutes

Surprising as it may seem, the question: how to use a sealant gun sometimes still arises; this question especially concerns novice craftsmen. And although this instrument is not particularly complex in design, some people who pick it up for the first time may even be stunned by it.

Advantages and disadvantages

A glue gun is perfect for applying sealant to any material. The joint will look smoother and more beautiful than a hand-sealed seam. The seam has the same thickness along its entire length. There are other advantages:

- immediate change of the sealing solution is allowed (if necessary);

- labor costs are reduced;

- durability of the air gun, resistance to damage, including from falling;

- the profitability of using sealant due to the available possibility of self-regulation;

- low probability of making mistakes when applying the product;

- noiselessness during operation;

- admissibility of use by non-professionals;

- the ability to use any type of sealant.

Air pistols have few disadvantages. If the device is connected to an electrical outlet, this will limit the possibility of its use. Pneumatic devices often weigh a lot; if you use them for a long time, your hands will get tired.

Such a tool is more expensive than an ordinary hand tool, but it will function much longer and more efficiently. When choosing an air gun, you need to decide for what purpose it is needed and how often it will work.

If the device is needed for one time at home, then it is recommended to use an inexpensive analogue; purchasing an expensive gun with a compressor will not be profitable.

Sealant gun - what is it?

If you look at the photos provided on how to use a sealant gun, you can generally understand what kind of tool it is and how the sealant should be inserted into it. But the very principle of its operation can present a certain complexity. After all, even its name causes confusion among a non-specialist. In fact, if you watch the video instructions on using a caulk gun, you can understand why this tool is called that. It also has another name - a syringe.

It got this name because of its structure and operating principle. The sealant composition is released from the plastic tube by pressing a kind of trigger, so this association arose with one of the types of firearms. There are several types of such tools and they can be divided into the following categories:

- by the type of compartments where the cartridge is inserted;

- according to the features of the device;

- using the silicone supply method.

If you look at the pictures, you will notice that such a tool can be of several types:

- battery;

- pneumatic;

- electric;

- mechanical.

Each gun is designed to be able to seal hard-to-reach gaps. The most common are mechanical tools, as they are a budget option.

Instructions on how to properly use a sealant gun

A caulk gun is used not only for interior repairs, but also for some exterior work in home construction. This tool got its name because of the peculiarities of its action. The sealant comes out when the trigger is pulled, which is why the tool is compared to this firearm. But this comparison, of course, is conditional, since the composition is squeezed out by a piston, which moves after the trigger is pulled. Therefore, it is more of a syringe.

How to use a caulk gun in pictures

How to use a syringe to squeeze out silicone?

It’s worth watching a video on how to use a sealant gun, and everything will become clear:

- Before inserting the cartridge from the syringe, you must pull out the metal pin. To do this, you will need to use two hands, since the pin itself will not extend, because it is held in place by a special clamp. When you pull the trigger with one hand, the lock releases the piston and it can be pulled out. But you need to pull it out to the very end.

- Now you can insert the cartridge into the gun and lock it with a few pulls of the trigger. But do not clamp it too hard, because first you need to prepare the tip of the cartridge.

- When the cartridge is fixed, the tip is cut off and a cone is screwed on, through which the silicone will be squeezed out. Cones come with ready-made holes (one for threads, and a second smaller one for sealant outlet) and without one hole. If there is no smaller hole, you need to carefully make a cut on the cone with a knife.

- In order to see how the sealant gun works, you should pull the trigger several times until the piston fully stops in the cartridge. The tool is ready and you can start working.

The cartridge cone must be placed at the place that needs sealing. After this, you can pull the trigger, activating the pusher, which will evenly squeeze out a sausage of sealant of the required thickness. When the pusher moves, the latch will also be activated at the same time so that the piston does not weaken its pressure on the bottom of the cartridge. To remove a used cartridge, pull the trigger to loosen the latch, pull out the pusher with the other hand and the cartridge will be released.

How to use a sealant gun - step-by-step instructions for a beginner

Sealant is a universal and simply irreplaceable tool in everyday life, which can be used to insulate seams and joints, provide water, moisture, heat and even sound resistance. In order for the sealant from the container to be distributed evenly and applied accurately, it is necessary to use a special gun. If you know how to use a sealant gun correctly, you can even ensure economical use of the substance. Therefore, it is necessary to familiarize yourself with all stages of instrument operation in more detail.

Preparing surfaces for sealant

Preparing surfaces before applying sealant is an important step in the work. The level of adhesion and type of coating will depend on its quality. Preparation process:

- To remove dirt and dust residues with a brush or vacuum cleaner, you can use a damp sponge, but then you must wait until the surface being treated is completely dry.

- Degreasing the surface with alcohol and acetone, paying special attention to the internal areas.

- A paint strip is glued on both sides, allowing you to limit the area where the product is applied.

- Drying the work area: wiping with a dry cloth or a hair dryer.

We suggest you familiarize yourself with how you can clean clothes from polyurethane foam