The initial stage of major renovation of the housing stock is redevelopment. Interior walls made of plasterboard are currently the most common type of dividing the area of apartments and houses into separate rooms. The trend in recent years has been new buildings that offer open-plan apartments. The total area in such apartments is not divided into separate rooms. Future owners are offered to plan the space themselves, zoning the premises into separate rooms at their discretion. For interior walls, plasterboard structures are most often used.

Interior walls made of plasterboard without plaster

Tools and materials

Before you start creating a plasterboard wall with your own hands, you need to prepare all the tools. The minimum list includes :

- Roulette

- Material (plasterboard)

- Knife for cutting material (or stationery knife)

- Rail

- Self-tapping screws

- Screwdriver

- Building level

- Lace (upholstery cord).

The lath can be of two options : metal profile or wooden veins.

Depending on which rail was selected, you may additionally need :

- Hangers for metal profiles

- Nails, dowels, self-tapping screws for fastening the slats

- Hacksaw for wooden slats.

Preparatory work

Before making walls with your own hands, you need to carry out a number of preparatory work :

- Measure the size of the room (height, width, length) to buy enough material.

- Decide whether additional sound insulation or thermal insulation will be needed.

- Make a sheathing (aka frame).

The first step in creating a frame will be drawing out the corners . It depends on them how even the room will ultimately be, whether there will be a diagonal in it. All angles are set to the building level. Next, a lace (upholstery cord) is pulled tightly between the corners. It is needed so that subsequent slats can be immediately leveled, evenly.

Intermediate slats are attached in increments of 60 cm. That is, each such step must have a vertically screwed rail. This parameter is determined by the width of the plasterboard sheet (1.2 m). In order for the sheet to hold firmly, it is necessary to grab it in three places: on both edges and in the middle.

If a metal profile is used , then the first step is to set the starting profile (guide). It is located around the perimeter of the entire room. Then the rest of the slats are mounted to it with a standard pitch.

Depending on the type of wall, you may need nails, dowels, or self-tapping screws to attach the slats.

The latter are preferable whenever possible. They provide the necessary mobility of the structure. In addition, if necessary, they can be easily adjusted to the building level to create a perfectly level wall.

Installing plastic windows yourself. You will read about this in our article. Video. And in this article you will learn how to finish the slopes yourself.

Selecting suitable materials

Scheme for assembling profiles for installing drywall.

Drywall is sold in standard sheets 120 cm wide, 250 and 300 cm long, 6, 9 and 12.5 mm thick. Conventional gypsum board type plasterboard consists of two sheets of thick cardboard, between which there is a solid gypsum mass. Gypsum plasterboard type GKLV is produced, which has increased moisture resistance. Through the use of special fillers, plasterboard acquires improved heat resistance (such as gypsum fiber board with fiber filler), increased sound insulation or acoustic properties. The most commonly used plasterboard is the GKL type, but in rooms with high humidity, GVL plasterboard is recommended.

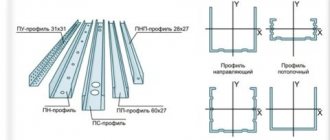

The frame of the partitions is made of metal profiles. For vertical placement, rack profiles (C-shaped) of the PS type are used. The standard ones have dimensions of 50x50, 65x50, 75x50 and 100x50 mm (the first number is the width, the second is the height of the sheet) and are available in lengths of 3 and 4 m. Guide profiles (U-shaped) of the PN type are mounted horizontally. Standard sizes are 50x40, 65x40, 75x40 and 100x50 mm. The profiles are produced in lengths of 3 m. When making a wooden frame, you can use a wooden beam 40x40 or 50x50 mm.

For the frame of the additional wall, you can use the same profiles as for the partitions, but it is recommended to use lightweight profiles with a wall thickness of 0.55-0.8 mm. It is enough to install the following profiles: rack-mount – CD (PS) 27x60; guides – UD (PN) 27x28. For a wooden frame, beams 30x40 or 40x40 mm are suitable.

Drywall installation

Before attaching sheets of drywall to the frame, take all measurements on them . If the leaf does not fit in height, it will have to be trimmed. This is done with a utility knife or a knife for cutting drywall. An incision must be made along the pencil line. Doesn't have to be too deep. Then the plaster simply breaks in this place, gently but sharply.

If the height of the drywall sheet is not enough, it will have to be increased. First, attach a whole sheet to the wall (from the ceiling), then measure the missing piece. Why is that? It is easier to attach a small element from below; the top will be perfectly level.

Installing drywall with your own hands is difficult to do alone. At least two pairs of hands are required. One person holds the sheet, the second grabs it with screws.

They need to be screwed in at approximately 15-20 cm increments. There is no need to tighten the material too much. The maximum immersion of the screw head is 1 mm.

After the walls are covered with plasterboard, you can proceed to the last stage - puttying the walls, grouting the joints . In this process, it is important to carefully process all seams, screw heads, and joints. The integrity of the wall and its decorative coating ultimately depends on this.

Installation process

After everything necessary has already been purchased from us, we begin construction.

- We make markings.

- We cut (or saw off) the height of the profile for plasterboard partitions.

- Using a level, we begin to attach the first vertical profile to the wall.

To do this, take the CW-40x50 profile, attach a level to it vertically, make sure it is perfectly vertical, and begin attaching the frame to the wall using a hammer drill.

Advice! If you have little or no experience, it is better to do this work together.

Having attached the profile, we take the next one for the floor. We insert them into each other and, following the existing markings, fasten the lower profile to the floor. In the same way, we install the profile for the plasterboard partition on the opposite wall.

Advice! In the place where the vertical and horizontal profiles join, before twisting with a self-tapping screw, clamp them with pliers, this will make the process easier.

All that remains is to attach the bar to the ceiling, which will fit into the vertical racks. If the width of the room is more than 3 m, you can attach a thread to the edges of the vertical posts and align the profile along it.

Next, we need to install vertical posts inside the resulting frame. To do this, we make markings, take a tape measure and a pencil, start with the first profile attached to the wall, mark 60 cm to the end of the partition along the floor plank.

We measure and cut the posts from the profile to the height. We insert the resulting blanks into fixed horizontal slats.

We align the bottom according to the marks so that the bar is located in the center of the profile. We fasten it using a screwdriver with a 3.5x13 self-tapping screw. We place a level on the inside of the rack, align the profiles along it and secure the top edge. We install the rest according to the same principle.

This is what the mounted partition should look like.

Marking horizontal jumpers

Installing horizontal jumpers

The next step will be the installation of horizontal jumpers to stiffen the frame.

We mark a distance of 60 cm from the floor on the outer stand, and make similar marks along the entire height. From these marks, using a level, we transfer the size to the remaining racks. We measure the length so that one edge fits into the vertical post, and the second in length reaches the middle of the second.

This is necessary in order to attach it using the “ears”, as shown in the photo.

The shelves are cut and bent

We insert the jumpers and secure them with self-tapping screws.

The final stage of work

Final stage

We lay the wiring and sew up one side with sheets of plasterboard. We lay mineral wool and install the sheets on the other side.

Advice! Leave a gap of 5 mm between the floor and the sheets, as well as on the ceiling.

Now we have come to the final stage. Now you can easily build a partition with your own hands.

Niches or columns made of plasterboard

Drywall is especially convenient for making unusual options in the interior - niches and columns. There is nothing special about making them yourself. It is important at the preparatory stage to set the slats and prepare the frame taking into account these niches or columns. The guide rails in this case are attached to the floor and ceiling. To make the structure more stable, you can make additional slats from timber, to which drywall will be mounted.

It’s possible to make plasterboard walls with your own hands. The whole process does not take too much time. It is important to carry out all the preparatory work most carefully, because this determines how smooth the walls will be in the end.

What to do if the parquet creaks? You will find the answer here. And here is an article about how to choose the right parquet.

Partition of complex shape

I would like to tell you a little more about how to make a partition with a complex design from plasterboard.

To do this, it is important to understand:

- how to make a semicircle;

- how to make shelves or niches.

To make a semicircle, we cut the stiffening ribs of the profile.

Creating a Bent Shape

Principle of operation

Before making shelves or niches, think about where you will have them. Next, we assemble the frame and sew it up with sheets.

Advice! When building a frame with shelves, it is better to take a 50x75 or 50x100 profile. When attaching a sheet to a cut plank, place a wooden block, this will prevent bending when fastening with a self-tapping screw.

Conclusion

Now you know how to install a plasterboard partition. In order to more accurately understand the technological and practical issue, our website provides detailed photo and video instructions in which you will find the necessary information on this issue.

Plasterboard partitions

Making plasterboard partitions is even easier than lining walls with them. In addition to standard tools and materials, you will also need :

- Wooden beam or metal profile;

- Soundproofing;

- Thermal insulation.

The last two can be foam sheets, mineral wool or angelin. If you use wooden beams to create partitions, then it must be treated with special means that protect against bark beetles, premature rotting and increase the life of the wood.

The thickness of the timber can be 5, 6, 7 cm. It depends on how thick the wall is needed.

The first step is to align the starting profile or timber to the level in the room. If a solid partition is intended, then the vertical profiles and beams are set in increments of 60 cm. To keep the wooden frame tighter, you can make ties between the vertical guides. This is also necessary if you plan to hang something heavy on the wall.

If the partition has an arch or doorway, you need to measure and mark in advance where they will be located. There must be vertical guides around the perimeter of the opening. From them the rest of the profiles and beams are set. All with standard steps.

If you use insulation and sound insulation , then it is more convenient to lay it when at least one side is covered with plasterboard. It is better to attach mineral wool in rolls to a construction stapler so that it does not crumble over time. Foam sheets are chosen of the thickness that the partition will be. Angelin, the thicker and denser, the better it copes with its task. You can also fasten it with a construction stapler. After all the necessary materials have been laid, you can sheathe the second side of the partition with plasterboard. The sheets are attached in the same way as when leveling the walls.

You will learn how roof sheathing for ondulin is made in this article. And here is about creating walls from plasterboard with your own hands.

Here you will find many more informative articles about building a house.

We build a plasterboard partition with our own hands

Attaching a profile to the ceiling

So, in this article we will answer the question of how to make a plasterboard partition in your own apartment without the help of professionals, the design of which will correspond to the overall interior. As it should be for drywall, you will have to prepare for the process, for which you need to study a document such as instructions for its use, watch a video, purchase all the necessary materials, namely:

- plasterboard sheets;

- metal guide profiles;

- self-tapping screws of two types: for metal and for drywall - all self-tapping screws from the piercing category;

- plastic dowels with screws and a metal wedge anchor used to mount the profiles to the ceiling, as the video shows.

Tools you will need:

- drill-driver;

- perforator;

- metal scissors;

- roulette;

- Laser level.

Let us note right away that interior walls made of plasterboard, as well as the ceiling, can be erected in three ways, here everything will depend on the amount of material used and what design will be chosen. So, the methods: simple installation with one-sided laying, double-sided and double-sided laying. As practice shows, the most common and popular option is installation using method number two. We will consider it. But let's watch the video first.

Frame installation

To do this, you will have to purchase two types of metal profile PN50 and PS50, that is, guide and rack-mount, which is necessary to make both walls and ceilings. The first step is to install a level, with the help of which a vertical line will be set for fastening the rack profile. Exactly along the indicated line, it is necessary to mount the profile to the wall and secure it using plastic dowels and self-tapping screws.

Attention! You should not drill the profile separately from the wall, apply it to the surface and drill through the places where the installation will be carried out, installing dowels, and immediately securing it with self-tapping screws, the distance between which should be within twenty to twenty-five centimeters.

Installing a second rack profile

In the same way, a rack profile is installed on the opposite side of the room, as shown in the video, that is, two profiles will define the wall. Next you need to install the guide profile on the ceiling. All the same operations as with walls, the only difference is the fasteners. In this case, it is best to use metal anchor wedges, the distance between which is the same 20-25 centimeters. If the length of the profiles does not allow you to cover the length of the partition with one element, then you can install two or one and a half profiles, or cut one of them to the missing size and connect the profiles by inserting one into the other.

Next, guide profiles are installed and secured to the floor, but with one condition - it is necessary to determine the design and size of the doorway, which will have to be preserved without installing the profile. Then it is necessary to mark on the floor the installation locations of vertical rack profiles, the distance between which is determined by an indicator of 60 centimeters. After which it is necessary to prepare the required number of racks, cutting them exactly to the size of the floor and ceiling. This is where metal cutting shears come in handy.

Install the vertical profiles exactly according to the markings so that they fit inside the guide profiles that are installed on the floor and ceiling. Align them vertically and secure them with self-tapping screws that will connect the racks and lying profiles. Start fastening from the floor, after which you can move to the ceiling, after first checking the racks for verticality.

Creating a Doorway

Measuring and installing the frame

Now you need to design the doorway, maintaining its design, for which you need to make a horizontal top crossbar. It will be made from the same metal profile. To do this, you will need a profile larger in length than the width of the opening. It will have to be prepared, that is, cut on both sides and made from it into a structure resembling the letter “P”. This structure is inserted into the opening so that the legs of the letter “P” look down. The crossbar is fastened at a height equal to the opening.

In order for the side rack profiles defining the doorway to withstand the loads, they are reinforced with wooden slats inserted inside, which are secured with self-tapping screws. That's it, the frame is ready for installing drywall.

Installation of plasterboard sheets

Installation of plasterboard sheets

Plasterboard sheets are installed to the frame in such a way that there is a space of fifteen millimeters from the floor to the sheet. Drywall is attached to metal profiles with black piercing screws. Fastening must be carried out along the entire perimeter of the sheet and in the middle, where the intermediate profile is installed, in increments of 15-25 centimeters. It is recommended to recess the screw heads into the body of the material to a depth of 1-2 millimeters. The distance from the edges of the sheet to the attachment point should be no more than ten millimeters.

In the event that one whole sheet does not cover the height of the wall opening, then one of the sheets will have to be sacrificed for cutting. The pieces cut to size are attached in the same order as a whole sheet. By the way, drywall is cut with a knife and then broken.

Attention! Solid and cut plasterboard sheets must be installed on the frame in a checkerboard pattern. That is, the first vertical row is a solid sheet at the bottom, trimmed at the top, the second row, on the contrary, is cut at the bottom, solid at the top.

Thus, the entire surface of the future wall is filled. On the other side of the frame, drywall is installed in exactly the same order. All that remains is to finish the plasterboard partition so that it matches the basic concept of the room’s interior, emphasizing the chosen design.