Metal swing garage doors, with a wicket, and also insulated.

Ours is engaged in the manufacture and installation of metal garage doors in Cheboksary and throughout the Chuvash Republic, as well as in neighboring regions. We offer you economical options for garage doors, equipped with everything necessary to begin operation immediately after installation. Customers are offered all types of metal garage doors made from 2, 3, 4 mm metal sheets, insulated garage doors, as well as from 2 mm solid sheet metal with rubber sealing.

If you set out to purchase metal garage doors , first of all make sure that your future purchase meets the following functional requirements:

— high-quality gates should be easy to use, easy to open and close; — good metal garage doors should work smoothly even in bad weather; — garage doors must have a high level of security; — reliable gates should provide effective protection of your garage from attacks by robbers and from the adverse effects of atmospheric phenomena.

The simplest type of gate is the swing garage door . They have an affordable price, ease of maintenance, and most importantly, a high degree of reliability. Such gates have a simple design, consisting of two metal leaves attached to the exit opening using hinges.

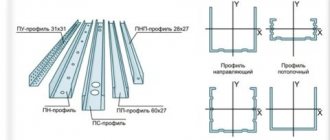

Here below are several types of swing garage doors based on metal frames made of a single angle 50x50 mm, 63x63 mm and 75x75mm, the leaves of which are made of profile pipes measuring 40x25x1.5mm; 50x25x2 mm or 60x30x2 mm. Garage doors have a metal leaf with a thickness of 2, 3 or 4 mm, which is painted with nitro enamel. All basic configurations of swing garage doors with a wicket are equipped with a reinforced 5-bar Elbor or Class lock with an increased security class. And also for more frost resistance and heat and noise insulation, we offer insulated garage doors from a 2mm solid metal sheet with sealing rubber or a 2.3.4mm metal sheet with a sealing strip and rubber. We insulate garage doors with URSA mineral wool or KNAUF mini-slab with internal door lining with 1 or 1.5 mm sheet metal or moisture-resistant plywood from 6 mm (any other material of the customer’s choice)

Preparation for construction

Preparatory work begins with choosing a suitable design. You will need project development and design drawings. When making a system with your own hands, you should choose a proven technology - a lever mechanism with a hinged mount. At the project stage, measurements of the garage opening are taken. This will allow you to correctly sketch the system.

The size of the gate is selected taking into account the parameters of the opening. The choice of size is also influenced by the mechanism used, which can be spring or torsion. The greatest width occurs in steel structures.

Before work, it is important to prepare a drawing with all dimensions. In terms of dimensions, the system should be 10 cm larger than the length of the opening. Adding centimeters will prevent gaps from occurring between the walls and the structure.

The dimensions of the opening are measured in width and height at several points. The dimensions of the frame must correspond to the parameters of the opening.

On this topic:

We build a garage from sandwich panels with our own hands

How difficult is it to build a garage from corrugated sheets with your own...

Choosing a floor covering in the garage

How to properly pour a concrete floor in a garage yourself

BACK FORWARD 1 of 5

In order not to spend money on development, you can take ready-made drawings. There are different plans - schemes from trusted manufacturers. Systems with gates, as well as automated structures, are in demand.

The height of the opening should be 30 cm higher than the top point of the vehicle roof.

Our prices for metal garage doors:

| Garage doors No. 1 Material for manufacturing metal garage doors: Frame: corner 50x50mm Leaves: profile pipe 40x25 Metal sheet 2 mm Painting of the gate: nitro enamel | Garage door with wicket No. 2 Garage door manufacturing material: Frame: angle 63x63 mm Leaves: profile pipe 40x25 Sheet of metal 2 mm Lock in the wicket: 5-bolt "Elbor" reinforced Gate painting: nitro enamel |

| Garage door No. 3 Gate material: Frame: corner 63x63 mm Leaves: profile pipe 50x25 Metal sheet 3 mm Painting of the gate: nitro enamel | Garage doors with wicket No. 4 Gate material: Frame: corner 63x63 mm Doors: profile pipe 50x25 Sheet of metal 3 mm Lock in the gate: 5-bolt "Elbor" reinforced Gate painting: nitro enamel |

| Garage door No. 5 Gate manufacturing material: Frame: angle 75x75mm Leaf: profile pipe 60x30 Metal sheet 4 mm Painting of the gate: nitro enamel | Garage door with wicket No. 6 Gate material: Frame: angle 75x75mm Leaf: profile pipe 60x30 Metal sheet 4 mm Lock in the gate: 5-bolt "Elbor" reinforced Gate painting: nitro enamel |

Garage door No. 7

Swing garage doors (frame size 2500x2500)

|

Garage door No. 8

Swing garage doors (frame size 2500x2500)

|

Garage door No. 9

Swinging garage doors with a counter jamb for masonry (brick, etc.) frame size 2500x2500

|

Garage door No. 10

Insulated swing garage doors made of solid bent sheet, 2mm metal (frame size 2500x2500)

|

Recommendations for use

In order for overhead garage doors to last for many years, it is necessary to take good care of them. The structure requires modern adjustment and repair.

It is important to follow the following recommendations:

- Regularly treat rubber seals with silicone. This will help prevent cracking and freezing.

- Lubricate the rollers and components of the lever system. The procedure will help prevent the occurrence of rust and extraneous squeaks.

- Adjust spring tension.

If there is visible damage, operation of the structure is prohibited. It is not recommended to drive the vehicle while the opening mechanism is in motion. During installation work, welding or drilling may be used. Welding is the preferred option. In this case, the frame is securely fastened and there are no additional holes in it. If the canvas weighs more than 100 kg, you will need a reinforced mechanism for fastening.

Garage door No. 11

Insulated swing garage doors, with 1 mm metal inner lining (frame size 2500x2500)

|

Installation of automation

Operating gates with an automatic electric drive can make life much easier. You don't need to make a lot of effort for this.

But it is worth considering that the electrical wiring system is complex and requires a direct connection to the house wiring. Additionally, a remote control is used, which can be portable or stationary.

The advantage is the use of an automatic mechanism and manual opening. Expensive solutions include hydraulic drive. This mechanism allows us to call the structures quick-lifting.

Automation installation consists of the following steps:

- The gate structure is checked for cracks.

- The drive is assembled taking into account the instructions.

- The guide beam is fixed in the center of the ceiling.

- The brackets are fixed at the rear of the guide. This is done using dowels.

- The drive is being installed.

- The lever is installed. One part is fixed to the sash, and the other to a cable or chain.

- Finally, the electrical wiring is installed.

- The device's functionality is checked.

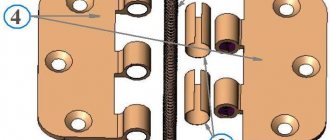

Loops

Hinges are a very important element of the design of swing gates; the reliability of the gate and its long-term operation largely depend on them. For swing gates we use hinges of our own making: regular hinges or on thrust bearings hidden in the body of the hinge, which easily accept unilateral axial loads. Such hinges ensure ease and smooth movement of gates even with very heavy leaves, almost unlimited time. There is also a convenient mechanism for lubrication of bearings using special grease nipples.

Features of insulation of the structure

Additional thermal insulation will help prevent heat leakage from the garage. For this purpose, foam finishing is used on the inside. This material is rigid and does not absorb moisture. Polystyrene foam is not difficult to work with, as it is light in weight.

You must first process all the gaps between the canvas and the frame. For this, polyurethane foam is used. This will protect the room from heat loss and drafts. Gate leaves are treated with paint or a special primer that protects the surface from rust. After the coating has dried, you can begin thermal insulation of the system.

In order for the gate to open easily, you need to adjust the spring by tightening the nut. For ease of use of garage doors, you should install an electric drive with a control unit. The drive must be suitable for a certain type of gate.

To protect the valves from freezing, they must be periodically lubricated with silicone grease.