What to paint with?

Wood is an aesthetically attractive material, but susceptible to various influences. It can be damaged by moisture, temperature changes in winter, ultraviolet rays and insects. Block house elements made from natural raw materials are no exception. Impregnations and protective paint coatings will help extend the service life of a wooden facade. A more expensive version of the block house undergoes industrial processing in autoclaves. The coating elements are impregnated with compounds that protect the wood from fire, rotting and the destructive effects of other factors.

Those who bought untreated parts should improve their properties themselves. This must be done before installation. It is advisable to process both the planks, the sheathing, and the base. Impregnations and stains are suitable for this.

Impregnations do not change the appearance of wood. All compositions can be divided into three groups:

- Acrylic water soluble ones are used for untreated wood. Good for interior decoration, as they do not have an unpleasant odor.

- Alkyd ones are made on the basis of white spirit and alkyd resins. They create a durable coating, but have a serious drawback - a pungent odor. Used only for facade work.

- Oilseeds are made from natural oils, most often linseed. The coating takes a long time to absorb and dry, but is durable. But it is incompatible with some paints.

Stains change the shade of wood towards darker tones. At the same time, they do not form a smooth layer or film on the surface. There are also colorless ones; they perform only protective functions. Compositions are produced on a water basis, as well as on the basis of alcohol, solvents and wax.

Decorative coating can emphasize the natural structure of the tree or change it in accordance with the owners' plans. In the first case, you should choose a transparent varnish or azure. If the surface of the parts is imperfect, paint will help hide some imperfections.

For decorative finishing of a block house, you can use materials, taking into account their characteristics.

Varnishes create a transparent or translucent film on the surface. Azures have the protective properties of impregnations and at the same time create a thin waterproof layer on the surface. They come in glossy and matte, transparent and tinted. Alkyd-urethane glazes make wood more resistant to mechanical damage. Paints - glossy, matte and semi-matte. For exterior finishing, it is better to choose oil rather than water-based finish. Wax – traditional finish with a matte sheen

It is important to remember that you can no longer apply varnish or paint on top of it.

Before painting the wall of a house covered with a block house, it is cleaned of dust or old coating. It is advisable to paint new parts before installation. Before applying paint, the wood is treated with a primer. It will improve the adhesion of the enamel to the surface. To work over a large area, craftsmen advise using a roller and painting hard-to-reach areas with a brush.

Decorating a block house inside the house

From the point of view of the quality of this finishing material, allowing its use inside the building, it is permissible to highlight further features. Let's look at them in more detail:

- Environmentally friendly, because it is a completely safe material that does not produce absolutely any negative effects on the human body.

- Lightweight and reliable. The presence of a block house for the purpose of interior decoration of the house does not create an unnecessary impact on other systems (neither the structure nor the foundation).

- Soundproofing. Block house, just like any other tree, provides a significant reduction in various hums of external sounds.

- Simplicity and ease of installation.

- Treating the blockhouse from the inside of the home allows the materials from which it is constructed to breathe.

For reference. Particular attention is paid to such a component as the indoor microclimate. The air here is saturated with oxygen and the intoxicating smell of wood, which allows us to talk about the medicinal properties of such a material as block house.

In addition, such a board allows you to quite easily combine or, on the contrary, highlight different elements of the building’s design; for example, beams with a reddish-brown coating will be the most expressive elements. So, with the help of a block house, you will be able to avoid unnecessary hassle regarding how to hide seemingly unnecessary, unnecessary interior elements.

Decorating the inside of a house with a block house

The first thing you need to take care of in this case is the correct choice of material.

As mentioned earlier, coniferous trees are best suited for interior decoration for these purposes. Any breed has its own, unique characteristics:

- The spruce tree has a lot of knots, and they form a unique sketch in the plane.

- Pine will show excellent structure, and their combination will create unusually clean and fresh air in the room. However, a lot also depends on what kind of premises the block house is used for.

- So, for example, if it is planned to treat the inside of a steam room with a block house (see Finishing a steam room: fundamental features) or a sauna, it would be more correct to beware of using the above-mentioned coniferous trees for finishing.

Advice. In this situation, boards of such species as poplar, linden or some small shrubs are more suitable. The problem is that when temperatures and vapors are too high, resins are released from coniferous trees.

- This material usually has a high density, therefore affecting its highest heat capacity. This creates favorable conditions for quick and relatively easy heating of the air in the steam room.

A house block made of coniferous trees heats up very quickly on its own, therefore, it is possible that during washing you can get burns if you touch the wall. Consequently, finishing a house with a blockhouse inside a sauna must be carried out in connection with individual requirements.

Blockhouse installation

Once you have accurately selected the type of material that will be used in your case, you can begin their direct installation. What you need to consider before installation:

- In order to ensure special expressiveness, the walls of a block house should be decorated with short and fairly neat boards, their maximum width should not be more than 10.50 cm.

- This approach will make it possible to advantageously decorate the wall with a convex plane and at the same time not in any way affect the safety of the volume of the room. The quality of manufacturing of the boards is also important.

- Everyone has their own views on this matter, so many cope with the installation of a domestically produced block house, others consider exclusively European and American standards, others are guided by some special ideals of their own, often exceeding the requirements of generally accepted building standards.

An excellent way to make your country home more comfortable and attractive is to decorate the inside of the house with a block house. At its core, a block house is an ordinary European lining, but the latest developments in the construction industry are used for its installation. The main advantage of the interior decoration of a house with a block house is the pleasant aroma of fresh wood. In addition, using materials from coniferous trees, it is possible to prevent the occurrence of respiratory diseases among residents of the house.

Options for wall decoration in a wooden house

There are many options for finishing a wooden house. It all depends on the operating conditions, finances, your desires and the style of the room.

Clean log house finished with paints and varnishes

If you strive for naturalness and environmental friendliness, and live in a region with a consistently dry and stable climate, then a log house made of natural wood is suitable for you.

In such a house you will always be haunted by the aroma of natural wood.

This type of finishing is increasingly gaining popularity among our stars. This original Russian style makes the room lively and the microclimate healthy. This type of finishing attracts with its beauty, durability, environmental friendliness, simple design and simplicity. Such projects can be recreated with historical accuracy in the way houses were built many centuries ago.

Lining as a wood finish for walls when it is impossible to sand the timber

Lining is a traditional material for home decoration. Its advantages are obvious - it is easy to install and looks quite aesthetically pleasing. The lamellas, with the help of special fasteners, are connected tightly.

Cladding with clapboard creates a perfectly smooth and beautiful surface

Other advantages of this material include:

- speed of installation;

- environmental friendliness;

- many shades of coating;

- made from different types of wood.

Among the disadvantages are:

- high price;

- the need to construct sheathing;

- the need for careful care.

Preparatory steps include not only the installation of the sheathing, but also the processing and inspection of the lamellas themselves

It is important to sand and dry them first.

The final stage is coating the lining with varnish, sanding and another varnishing.

Block house is a more modern type of lining. Typically, such blocks are made from high quality wood, which does not shrink, is not inferior in strength and strength, and in many ways even surpasses classical materials.

In addition, this finishing material does not lose its original quality due to wood processing. The texture of the material is no different from natural wood.

The main advantages of a block house:

- mechanical strength;

- environmental friendliness;

- aesthetic appearance;

- light weight;

- ease of assembly.

For interior decoration, slats with a thickness of no more than 25 mm are better suited. As the thickness increases, difficulties may arise with high-quality fastening of the sheathing. In addition, this can lead to a reduction in the internal space of the room, which is extremely undesirable. The disadvantages of the material include too low vapor permeability and increased flammability.

If you purchase material in winter, it is important to place it in a warm room to dry it

Finishing a wooden house inside with plasterboard

Drywall is the ideal solution for those cases when you need to hide or hide something. This could be some kind of communications, or planning defects. Typically, drywall is used to level walls. Most often, in a wooden house, plasterboard is used to finish ceilings or erect interior partitions. In addition, such coatings will be a good solution for bathrooms.

Drywall with a moisture-resistant coating can protect your bathtub walls from excess moisture

In addition, plasterboard is made in a fire-resistant version. This is exactly the case when it can be used to cover fireplaces or stoves, additionally protecting wooden walls from overheating and fire.

For wooden houses, timber sheathing is used as a base for drywall

Wall panels of various types

Wall panels for finishing a wooden house are quite a popular option. The choice of materials is quite large. The finish with natural veneer, as well as with laminated MDF, which is not afraid of moisture and can replicate almost any texture, looks very interesting.

MDF boards can imitate patterns not only of wood, but also of leather, bamboo, and plaster

What are the benefits of wall panels:

- simple and easy installation;

- good heat and sound insulation;

- stylish appearance.

The panels are also convenient because they can be selected to suit any size. They are also attached to the sheathing and have a tongue and groove fastening system. Externally, the seams are almost invisible. The coating looks like a single monolith.

Decoration with MDF boards can be selected to suit any interior

Related article:

Choosing wood for interior decoration

In order to decide which material to use for the interior decoration of a country cottage, you need to explore all the options for using wood for a block house with their advantages and disadvantages. Some types of coniferous and deciduous trees are used for the manufacture of interior cladding.

Moreover, the resin contained in coniferous species provides additional waterproofing and aromatherapy effect in such rooms.

The choice of wood for finishing depends on the operating conditions of the room.

The choice of possible options for materials for interior decoration of a block house is as follows:

- Larch. Moisture-resistant, dense and difficult to rot wood, its processing is very labor-intensive due to its special strength. Considering the high cost of this type of wood, it is most often used for exterior decoration, but if the cost of the material is not scary, then for internal use this wood will justify the additional costs due to the special wear resistance of such a house, its immunity to moisture and its expensive appearance;

- Pine. It is much easier to process and cheaper. The board made from the butt part of the tree is of high quality, with a beautiful texture, and in some ways it is inferior to a board made from larch. Can be used both outside and inside;

- Spruce has a loose structure and has many knots. Its use for interior decoration is extremely limited due to its low quality;

- Hardwoods - aspen and linden - are used quite rarely, although linden is often used to decorate baths and saunas, and in this it has no equal.

The method of connecting block house boards (groove-tenon) ensures the absence of gaps

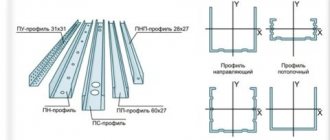

Installation of sheathing

Assembling the puzzle inside the house begins with a frame made of beams. Both the primer for plaster and the blockhouse require preliminary installation in the form of lathing, otherwise the final result may be distorted over time. It is unlikely that anyone will want to live in a kingdom of crooked walls.

Detailed blockhouse installation diagram

This manipulation during installation often involves attaching beams with a diameter of 0.20 - 0.30 cm to the base. One of the simplest methods of fixation is universal self-tapping screws; nails can also be useful.

- Horizontal or vertical? When the house block is in a horizontal position, the sheathing bars are attached vertically, and vice versa. If necessary, the board must be adjusted to the required thickness. If you don’t have woodworking skills, you can put something under it (to make it bigger). Careful preparation of the sheathing will give you the opportunity to get a perfectly smooth wall.

- The saving level will control surface differences of 5 plus.

- Between the boards there are special compounds to retain the heat of the vapor barrier.

Blockhouse installation technology

Panel installation

The main advantage of a wooden block house is its ease of installation, which anyone can do. The most difficult and time-consuming stage of this process is preparing the walls for installation of the covering and constructing the frame. Before attaching the panels, you need to study the sequence of actions. It is as follows:

- Preparing the base. The walls must be freed from decorations and unnecessary structural elements.

- Alignment of walls. If the unevenness is not very pronounced, the walls can be left in their original form. If the radius of curvature of the wall can complicate the installation of the frame, it is better to level the surface.

- Frame installation. If the house is made of wood, siding can be installed directly on the walls. Stone walls need it. The frame for the insulation is made of galvanized profile. The fastening pitch is 0.59 m, since the width of the insulation sheet is 0.6 m.

- Insulation. The choice of insulation remains with the owner. This can be mineral wool, glass wool, or polystyrene foam. Sheets of material are inserted inside the skin, into the cells formed after installation of the profile. The outside of the insulation must be covered with a vapor barrier film.

- Manufacturing of counter-lattice. Block house siding made of pine should be installed on it. The installation principle is simple: relative to the starting frame, this structure is attached perpendicularly.

- Installation of panels. It occurs using fastening strips fixed around the perimeter of corners, in the openings of windows and doors. If double-fracture panels are used, installation is carried out from below, but if the siding is single-fracture, then fastening occurs due to the reverse lock. This means that the fastening should start from the top.

Siding is gradually displacing materials considered obsolete from the construction market. Lightness and practicality, the ability to choose colors, durability make it an excellent solution for every owner who strives not only to give his home an aesthetic appearance, but also to make it warm, comfortable, and convenient for living.

Material selection

Decorative finishing should begin with the selection of materials. The block house is divided into several types depending on the type of wood and class of material.

Wood type

Block house slats can be made from several types of wood, differing from each other in texture, color, technical properties and cost.

The table shows the comparative hardness of some types of wood used for interior decoration.

Use coniferous wood for residential premises

For residential premises - living rooms and bedrooms, it is recommended to use coniferous wood. The subtle pine smell that will emanate from the walls and ceilings will have a calming effect on the nervous system of the inhabitants of the house.

In addition, the resin of coniferous trees has antiseptic properties, preventing the development of pathogenic bacteria in the room.

For cladding interior spaces with high heating temperatures (saunas, baths), it is recommended to use deciduous wood, since coniferous wood varieties tend to release excess resin when heated.

For finishing a bath, it would be optimal to use larch

You should also take into account such a factor as high humidity, so decorating the walls of a block house in such rooms involves the use of wood that is resistant to dampness.

At the same time, an important criterion for choosing the type of wood is personal preference. After all, the main purpose of decorating a wall with a block house is to create an interior that is pleasing to the eye, so if you like the openwork texture of Karelian birch or beech, purchase just such a material.

Panel size

Use thin panels to decorate rooms

When choosing panels, you should also pay attention to their size. Typically, the width of the lamellas ranges from 80 to 230 mm, but there may be exceptions to these rules

Wider panels are used to decorate the facades of buildings, since inside the house they will look too massive, creating an oppressive feeling and “eating up” the space.

As practice shows, for interior decoration it is better to take thin lamellas, 8–16 cm wide. The thickness of the lamella can be from 20 to 50 mm. The length of the block house slats can vary from 2 to 6 m, so when choosing a material, this parameter should also be taken into account so that there is as little production waste as possible.

Material class

Extra-class materials have a high price

In addition to the type of wood and size, the block house is also divided into classes depending on its quality.

It has enhanced decorative qualities; first of all, it is characterized by the almost complete absence of knots and other cosmetic defects. However, the cost of such a block house is quite high.

The next class of material is “A” and “B”. They have a larger number of knots, and some other defects are acceptable on their surface.

The cost of such material, accordingly, is significantly lower than that of the extra class, but if you are not too demanding of quality, then you should pay attention to this economy class option. Moreover, repairing small chips or dents is not difficult

Features of internal installation of a block house

In each case, the blockhouse used to decorate the house can be mounted on surfaces made of different materials. However, regardless of this, a mandatory requirement for it is the presence of sheathing. It is made using bars reaching a thickness of 30-40 mm. The finished bars are mounted to the wall, placing them at a distance of 50-60 cm from each other, making sure that they are aligned in height. This reveals an additional advantage of this method of finishing a room: by using a block house to decorate a house, the need to level the walls before carrying out work disappears.

Installation technology

According to the facade finishing technology, before installing a blockhouse, you must first perform thermal insulation. But if this work is carried out inside the house, then nothing bad will happen if the owner decides to ignore this recommendation. First of all, this applies to premises that are built of brick and wood. However, you need to think about this before work on installing the sheathing begins. The fact is that if you include insulation in the list of necessary works, this will require increasing the thickness of the bars. The presence of free air space between the wall and the cladding has a certain positive effect, which ensures better noise protection of the house.

Regardless of which side of the room the block house is attached to, this work is carried out horizontally along the vertical sheathing. However, sometimes you can resort to the vertical installation method. First of all, this applies to those rooms where high humidity prevails. Therefore, this approach should be used for saunas and baths. By acting in this way, you can prevent water from accumulating in the grooves of the board and avoid destruction of the wood.

If we talk in more detail about the technology of such installation, then it is especially important here that the tenon of the first and subsequent boards is located in the direction of the light source. Thanks to this, it will be possible to hide the joint of the boards as much as possible. This solution is as effective as gluing wallpaper overlapping. However, this installation method is resorted to in rare cases. The most commonly practiced method is to attach a block house horizontally, where the tenon is located on top and the groove is located at the bottom of the board.

Another important feature of finishing work using a block house is that the wooden material must lie in the room without packaging for several days. Such exposure will allow the block house to acquire environmental humidity.

As a starting point for installing a block house, you can choose the upper or lower boundary of the house wall. In this case, most often, nails or self-tapping screws are used to fasten the material, which are driven into the tenon at an angle. For such an installation scheme, it is most preferable to fasten the material from below, since this eliminates many inconveniences. Instead of traditional blockhouse fastening elements, special brackets and clamps can be used. In this case, it is possible to ensure high quality and reliability of fastening the material, although this leads to an increase in its cost.

Basement siding

Basement siding is used to finish a building in the base area. This cladding is made to protect the lower part of the house from the aggressive effects of precipitation and constantly operating mechanical factors.

Finishing the base with siding

To eliminate their harmful effects, cladding should be used, the thickness of which should exceed 3 millimeters. To solve such problems, installation of basement siding is used.

Basement siding

Individual elements of the building material have a relatively large thickness and are made in small sizes in order to ensure reliable fastening and reduce the likelihood of spontaneous destruction of the structure due to its large weight, which does not correspond to the fastening method used.

Attaching basement siding

To give a house a presentable appearance, they often use basement siding, which will not only provide reliable protection for the lower part of the building, but will also play an effective decorative role.

Basement siding also plays a decorative role

In accordance with the requirements of the owner of the building, you can select elements of basement siding that imitate various materials: wood, brick, stone. To ensure an affordable level of cost of building materials intended for the construction of a basement structure, manufacturers often combine it with affordable raw materials.

Basement siding imitating brick

In some cases, cement siding is used to cover the lower part of the building. It should be taken into account that in order to perform the functions assigned to the structure, its height should not be lower than 15 centimeters from ground level.

Finishing the base with cement siding

The advantages of basement siding lie in the possibility of its long-term use, the period of which practically corresponds to the life of a residential building, during which it will not be necessary to carry out work to eliminate damage caused by mechanical force or natural adverse factors.

In a house whose cladding is made in the style of basement siding, rodents cannot appear, due to the reliable protection of all walls from the possible entry of uninvited guests. The construction material does not crack and maintains a respectable appearance for a long period of time.

Basement siding has a long service life

When purchasing siding elements made from various materials, you should consider:

- thickness of the structural element;

- presence of defects on the surface;

- availability of certificates of product compliance with regulatory requirements;

- manufacturer's warranty.

In general, buyers prefer to equip their homes with cladding made from natural materials, due to their environmental friendliness and hypoallergenicity.

Types of basement siding

When choosing elements for a future structure, materials whose appearance imitates natural wood or stones are popular. Wooden siding is less popular in building cladding due to its high price and short-lived product life.

Basement wood siding

All types of siding can be easily washed when dirty. For convenience, a garden hose is used for such purposes, under the pressure of water from which any dirt can be easily removed with a sponge.

Siding needs regular washing and cleaning.

Covering a bathhouse with siding

Siding - decorative panels of a standard size: width - 22 cm, length - 125 cm. The material can be metal or vinyl, has more than 10 colors.

To cover a bathhouse made of timber with siding, you must first install a profile frame or wooden sheathing on self-tapping screws. All installation work can be done independently. The surface of the walls is carefully treated with antiseptic compounds to prevent the formation of mold and harmful microorganisms.

The siding is installed in a horizontal position with a distance of 20 cm from the foundation of the building.

Covering a bathhouse with siding has the following advantages:

- protection of the facade from precipitation;

- resistance to temperature changes and fading;

- inertness to deformation and mechanical damage;

- Fire safety;

- absence of toxic elements;

- good air permeability;

- low level of moisture absorption;

- accessibility of installation.

However, the material has some disadvantages:

- high cost of individual fixing elements of the structure;

- the appearance of deformations and play due to violation of installation technology;

- the need to create a flat surface for fixing the panels.

Advantages and disadvantages

Each type of siding has its own advantages and disadvantages. They are determined both by the initial characteristics of the material and the quality of the equipment used. Metal siding-log block house has the following advantages:

- fire safety;

- resistance to ultraviolet rays;

- resistance to too high and too low temperatures;

- no need for updating and processing;

- environmental friendliness and health safety;

- durability;

- ventilation;

- ease of installation;

- variety of colors: walnut or mahogany, delicate linden or light pine;

- low cost.

The only disadvantages of this type of material include low thermal insulation properties. When using metal panels, you should pay special attention to the choice of insulation option for a residential building.

Vinyl siding block house also has many advantages:

- color as close as possible to the real one, for example, walnut;

- compatibility with various types of materials;

- ease of care;

- practicality, long time of use;

- fire safety, rot resistance;

- resistance to mechanical stress;

- resistance to atmospheric influences;

- availability;

- ease of installation.

A disadvantage that can stop a block house from purchasing vinyl siding is the fragility of the panels, as well as the possibility of deformation in the event of strong impacts.

Self-finishing technology

Specialists are hired to decorate the house, but to save money you can do it yourself. When covering a room with a block house yourself, you must follow the following rules:

- Before starting installation work, wooden boards must be left in the room for several days. This is done to reduce the moisture content of the material.

- The board must be fastened along the guides.

- When attaching panels, they should be installed so that the tenon is on top and the groove is on the bottom. This installation allows you to minimize the entry of dust or dirt into the grooves.

- When installing, you need to leave a small gap between the floor and ceiling, which will serve as natural ventilation.

- The panels should also have a small gap between them. If moisture enters or temperature changes, this arrangement will prevent deformation of the material.

- Galvanized materials should be used as fasteners to avoid rust stains.

Preparing the block house

Before installing a block house in any part of the house, you need to wait some time so that the new beams go through the process of adaptation to the climatic conditions in which they will be located. The tree's susceptibility to natural decomposition makes it a good breeding ground for many insects and various forms of microflora. An important stage of preparation is the impregnation of wooden elements with antiseptic agents, which can significantly increase the resistance of wood to biological damage. Treating wood with a fire retardant increases the material's resistance to fire and mold.

Assembling or installing the frame

The complete assembly of the frame can be divided into five stages. During installation, some of the listed steps can be skipped in cases where there is no need for additional insulation of the room. Let's look at the installation steps:

- A vapor barrier material is attached horizontally to the wall. To fix it, you can use nails, but it is more convenient to use a construction stapler.

- Sheathing bars are attached on top of the waterproofing. It is also recommended to install the first layer of sheathing in a horizontal position.

- Thermal insulation material is installed in the cells of the sheathing.

- After the insulation, the waterproofing layer is installed again.

- At the last stage, the second layer of sheathing is fixed, which is now in a vertical position.

When installing, be sure to fix it level, since the block house will be installed on it.

Installation

The panels are mounted from the bottom corner in a horizontal position, along a pre-assembled sheathing. To fix the board, gluers are used; they are attached with self-tapping screws to the frame. A sheathing panel, which is positioned with the groove down, is inserted into the fastener tabs. The next board is placed with a groove on the tenon of the bottom panel. This procedure is repeated until the entire wall is finished.

If you refuse to use gluers and use self-tapping screws as fasteners, installation begins with preparing the seats for them. The fastening step is approximately 40 cm, and the self-tapping screw is screwed into the tenon with an inclination of 45 degrees. To give an aesthetic appearance, the fastening material is masked.

Finishing the corners is the most difficult. At this stage, when carrying out work, special elements are used to design internal and external corners. However, they do not always allow you to completely hide all the cracks, so for masking they use planed timber, which is attached before the sheathing begins. This design allows you to fix the boards of the block house directly to the timber and gives the cladding an aesthetic appearance.

Decoration methods

To give the surface of a block house improved properties and the required color shade, special impregnations that contain pigments and oils are used. Acrylic, alkyd, oil – these are the bases used for painting materials. Glazing paints, absorbing into the wood, cover it with a uniform layer and do not create smudges. They enhance the natural beauty of the patterns. Painted timber stands out noticeably against the background of untreated boards.

In addition to glazing compounds and various impregnations, wood paints are used. They are made on a water basis. Organic and synthetic solvents are also used. Paints have their drawbacks that should be considered when using them inside the home. They hide the natural structure of the wood and emit an unpleasant odor. To paint timber, colored and clear varnishes and stains with a rich range of shades are also used.

Installation technology

Joining herringbone boards at the inner corners of the room

Interior finishing with Blockhouse requires the installation of a load-bearing sheathing structure onto which the finishing panels will be attached. The sheathing is positioned strictly vertically in increments of sixty to eighty centimeters. The diameter of the timber for the sheathing is recommended - 30 - 40 millimeters, this will be quite enough. It is advisable to treat the timber for the sheathing with a disinfectant primer for deep penetration wood.

Important. The timber for the sheathing structure must be absolutely dry. The installation instructions allow a material moisture content of no more than sixteen percent. This requirement is due to the fact that when drying, the wood is deformed and the finish may “sink.”

For interior decoration, a Blockhouse with a small thickness - up to one hundred and fifty millimeters - is suitable. The large thickness of the material takes up the usable area of the room and requires the installation of a more powerful sheathing structure, which is impractical for interior decoration.

Facing the room with horizontal panels

There are a lot of photos and videos on the Internet about the step-by-step installation of Blockhouse panels, so we will focus on the most important points of the work:

- Installation of horizontal cladding begins from the bottom up, securing the bottom panel of the material strictly horizontally. The correct installation is checked using a water level and a plumb line.

Important. It is impossible to navigate when installing on the floor covering. Finishing the interior walls with Blockhouse suggests that the first panel must be placed strictly horizontally, leaving a gap of up to five centimeters, depending on the floor level. Then this gap can be decorated with false skirting boards. In addition, such gaps provide unhindered ventilation of the space under the cladding.

- Before installing the load-bearing sheathing, the surface of the walls must be cleaned of old finishing and dust;

- Installation of vertical cladding panels begins with setting the left corner strictly vertically. I would like to draw your attention to the fact that you need to focus not on the walls of the room (they may be uneven), but on the measuring instruments.

- The facing material must be absolutely dry. If you plan to paint the panels, then this must be done in advance, because after finishing it will be difficult to paint the side joints of the lamellas.

For which houses is a wooden block house suitable?

A wooden block house can be used on all houses without exception. The paneling creates the effect of a hut or tower; rural design motifs are used. The finishing style corresponds to centuries-old traditions.

There are no contraindications to installing the material; there are only normal technological requirements. If external insulation is used, then, depending on its type, it may be necessary to create a ventilation gap (for vapor-permeable materials such as mineral wool) or its absence (for impermeable types such as polystyrene foam, polystyrene foam or EPS).

A wooden block house requires periodic maintenance - applying a layer of varnish or painting. This need is due to the inherent qualities of the material and has nothing to do with the construction of the house. Periodically applying a coat of paint has a positive effect - the appearance of the house is updated, the cladding is refreshed, becomes brighter and newer.

Under the timber

The timber block house has a more austere and collected look. A canvas made of such material looks like a wall made of high-quality planed timber, although structurally it can consist of any material.

The walls look smoother, the presence of planes makes the canvas neater. The style of the house and the manner of decorating the facade are more urban and tend to use architectural decorations

A block house built under timber creates a more modern look for the house than when using panels made under logs. The walls look smoother, the presence of planes makes the canvas neater. The style of the house and the manner of decorating the facade are more urban and tend to use architectural decorations.

Metal

A metal block house is a type of metal siding with a panel profile designed to look like timber or logs (for example, golden oak). The similarity to traditional wood panels is purely external. The technical characteristics and performance qualities of the material are typical for galvanized steel siding.

The metal block house has high strength and is resistant to external loads. At the same time, it has low sound insulation, which is noticeable when it rains. Installation of the material is quite simple and does not require special preparation; the only condition is the creation of temperature gaps and loose fastening of the material to the support system, which allows movement during expansion from heating.

A significant difference between a metal block house is the absence of the need to maintain the canvas. The material is manufactured in different modifications and has a wide selection of colors. The kit includes all the necessary components created for the design of corners, openings, junctions and other elements of the facade.

Vinyl

A vinyl block house, like a metal one, has only a decorative resemblance to a wooden prototype and has its own qualities and characteristics. The material is very elastic, which allows it to respond painlessly to small mechanical loads. Absolutely not susceptible to corrosion, exposure to water, and frost-resistant. At subzero temperatures it becomes more brittle and can crack under mechanical stress.

When installing, you should follow the same rules as for metal siding - creating temperature gaps and loose fastening of parts to the subsystem. The peculiarity of the vinyl block house is the low weight of the panels, which makes it possible to use it on any home without exception.

What is attractive about a block house?

This material itself looks like an ordinary board, which is made in the form of a cylinder and has a groove and a ridge on the edges. But still, the interior of a house, which is decorated using a block house, looks somewhat different than when using traditional materials. Photos of the interior will tell you best about the interior decoration of a block house.

Advantages of a block house

The characteristics of the block house deserve special attention. which in many ways made it a popular material for use in interior decoration:

- Environmental friendliness. The use of a block house does not cause any harm to human health.

- Lightness and strength. When choosing this material for finishing a house, you can be sure that it will not create excessive loads on the building’s load-bearing structures and foundation.

- Soundproofing. Being a wood-based material, block house is able to effectively deal with various noises, reducing the discomfort caused by them.

- The use of block house for interior decoration gives the building breathability.

- Indoor microclimate. Thanks to the use of this material for finishing, the air is saturated with the smell of wood and resin, and has a healing effect on people in the room.

It is equally important that this seemingly ordinary board material can look effectively against the background of other elements of the room’s design, including beams, brickwork, and forged parts. And, judging by the photo of the block house, everything is exactly like that.

The unusual appearance of this material, which is associated with walls cut from logs, also attracts attention. A house decorated with a block house creates a feeling of warmth that does not leave a person even for a minute. Therefore, photos are the best way to learn more about decorating a room with a blockhouse.

Design solutions

A thin and light block house is suitable for covering both a city apartment and a country house. Moreover, the latter does not necessarily have to have a massive base; cladding a frame house is a fairly common practice in private housing construction. Moreover, there are many ideas for cladding.

It is not at all necessary to cover the entire room with a block house; it can be a specific area. The material goes well with stone, brick, and tiled surfaces.

The block house can be combined with other wooden textures (boards, lining), as well as delicate, noble textiles. This warm natural material combines harmoniously with forged and glass elements.

A block house is the best option for recreating the atmosphere of a house in the Russian style - an expensive merchant house or a more laconic, in some ways even ascetic peasant house. Interior styles such as chalets and the atmosphere of a small hunting lodge are also impossible without the use of wood.

Due to the environmental friendliness of the material, it can be used not only in the living room and hallway, but also in bedrooms, dining rooms and even children's rooms.

Covering an office with a block house will add rigor, respectability, and emphasize the status and good taste of its owner. It is better to choose a material of a darker shade, combining it with matching furniture, natural leather, and original design elements.

For living rooms and bedrooms it is better to choose lighter options; it is possible to combine several types of block houses with different textures

If panels for rounded logs are used, they will attract attention. In this case, furniture and accessories should have simple shapes and be quite discreet

When finishing a bathroom with a block house, it can be turned into a luxurious boudoir. Typically, light-colored material is also used here. As an option - bleached wood. For more aristocracy, you can add dark “logs”. When choosing this cladding option, you should carefully treat the wood with water-repellent compounds.