Application and processing of wood panels

For the production of flat furniture parts, carpentry, fiber boards, particle boards, plywood, as well as frame panels are used.

Blockboards consist of an inner layer and two outer layers, which are glued together under pressure and temperature.

Slat-filled wood panels require a significant amount of valuable raw materials. They have high flexural strength and should be preferred when producing parts that will experience heavy loads. When cutting such slabs, large amounts of waste are obtained, since it is necessary to take into account the direction of the fibers of the facing layer and the lath filling.

Many businesses use waste solid wood from millwork and particleboard for secondary purposes to reduce overall waste. After cutting the slabs, the slats are tied or glued (at individual points) and lined with plywood or fiberboard. The flexural strength of such boards is lower than the flexural strength of commercially produced wood slabs, and their scope of application is limited to products that require lower quality requirements.

For such kitchen furniture, mainly frame panels with various internal fillings are produced. These shields are manufactured to precise final dimensions. The internal filling consists of corrugated cardboard, strips of fiber boards or plywood glued together to form a lattice, paper impregnated with resin, and boards of rigid polyurethane foam, which are covered on both sides with fiber boards. These designs save wood and are dimensionally stable, but in most cases require significant labor to produce. Such boards are used primarily for the manufacture of doors and furniture walls that are not subject to bending loads.

Flat-pressed particle boards and fiber boards have a high density, which is due to the production technology and their structure. They swell a little and shrink along the length. The consumption of raw wood in their production is lower compared to the wood consumption in the production of joinery and plywood boards and is partially covered by the use of low-grade wood. These advantages and the ability to carry out semi-automatic production underlie the national economic importance of the production of particle boards and fiber boards. Due to the absence of fiber direction in the structure of these boards, it is possible to rationally cut them. Taking into account the structural features is only required conditionally. The surfaces of the slabs can be lined and finished in various ways. It is advisable to process plates with carbide tools due to their high density and synthetic resin content.

While thin fiberboards are mainly used as back walls and drawer bottoms, flat-pressed particleboards and medium-density fiberboards with a thickness of more than 10 mm are intended for the production of flat structural groups such as doors, walls and shelves . Extruded particle boards have limited use in furniture making and must be covered as the flexural strength of these boards is very low.

Plywood is mainly used for the manufacture of furniture back walls and drawer bottoms, since it has very high strength and, if the outer layer is of good quality, can only be varnished and sanded. However, during its production and cutting, significant overall waste is generated. Therefore, plywood is increasingly being replaced by solid fibreboards.

Payback

Total investment expenses in the first year of business (premises, equipment, raw materials, registration, personnel): about 3.4 million rubles. (Moscow), 2.9 million rubles. (regions). Likely additional costs (per month):

- transportation of furniture (100 thousand rubles);

- advertising (30 thousand rubles);

- current repair of equipment (10 thousand rubles);

- utilities (5 thousand rubles).

Total additional expenses per year: about 1.7 million rubles. Total expenses in the first year of business: 5.1 million rubles. (Moscow), 4.6 million rubles. (regions).

Above we provided calculations regarding the possible intensity of furniture production in the workshop. If an entrepreneur manages to achieve the indicators for assembling kitchen sets (5 sets per month), then with the average market selling price of a set of 40 thousand rubles. he will have the opportunity to earn about 200 thousand rubles for them.

Assembling cabinets, when we reach the figures we have considered in terms of assembly intensity, will bring in about 150 thousand rubles. per month. Revenue in the table production segment will be about 100 thousand rubles. per month. Maximum annual revenue: about 5.4 million rubles. It will provide a profitability of about 6% in Moscow, 15% in the regions in the first year of business.

Based on the recoupment of expenses for modernizing premises and equipment (from the second year), profitability can increase to 12% in Moscow and 19% in the regions.

Selection and application of veneer

Veneer is thin sheets of wood that are glued to supporting structures. Depending on the production method, veneer is distinguished, planed and peeled; depending on its purpose, it is divided into facing, sub-facing and reinforcing.

Facing veneer is made from decorative wood (mostly planed veneer) with a thickness of less than 1 mm. First of all, it determines the appearance of the furniture.

Sub-cladding and reinforcing veneer performs structural tasks. This veneer is made from cheaper wood species with a thickness of 0.7-1.8 mm by peeling. In most cases, the texture and color of peeled veneer does not matter.

When cladding extruded particle boards, first of all, the goal is to increase their bending strength. For this purpose, peeled veneer up to 2 mm thick is used, which is glued so that the direction of the veneer fibers is parallel to the direction of production of the boards.

Of great importance is the gluing of wood boards with veneer made from cheaper wood species, with a weakly defined structure, which until now has been used only for secondary purposes. After veneering, a pattern of decorative wood texture is applied to this veneer using one to four cylinders using printing.

Thanks to the presence of pores in the veneer, the imitation looks so believable that even a specialist finds it difficult to distinguish veneer with a pattern printed on it from genuine veneer. This economical method allows, under certain circumstances, to achieve significant savings and make the most efficient use of veneer. For example, sapwood walnut veneers, which were previously largely wasted, can be excellently used for wood grain printing.

When choosing veneers, the main focus should be on ensuring sufficient stress equalization to prevent warping. Since different types of wood swell and shrink differently in the tangential and radial directions, one side of the product cannot be faced with peeled veneer and the other with sliced veneer, even if the veneer is of the same type of wood. In rotary cut veneer, veneer shrinkage along the width always corresponds to tangential shrinkage; in sliced veneer, it mostly corresponds to radial shrinkage. Cladding with veneer of varying thickness leads to significant stresses due to changes in humidity and ambient temperature.

Room

You will have to rent premises for starting production for a long time, having budgeted for the required volumes. To produce economy-class furniture (this is the segment that novice entrepreneurs are recommended to enter, especially if we talk about starting a business during a crisis, when “premium” goods become less popular), you will need a premises of about 50 sq.m.

This will allow you to open a small workshop for processing materials and assembling such types of furniture as:

- kitchen sets;

- cabinets;

- tables.

Room structure:

| Room | Area, sq.m |

| Shop | 30 |

| Stock | 12 |

| Utility room | 8 |

| Total | 50 |

Approximate prices for renting premises: 300 thousand rubles. per year (Moscow), 200 thousand (regions).

Possible costs for upgrading communications:

- Laying power cables capable of servicing powerful equipment (hammers, miter saws, etc.);

- Equipping the premises with a unit for washing materials;

- Purchase of tables, racks for parts and materials.

Estimated additional investments in modernizing the premises (one-time): 150 thousand rubles.

Total one-time investment in premises in the first year of business: 450 thousand rubles. (Moscow), 350 thousand (regions).

Application of molded parts from chips

Currently, parts molded from chips are increasingly being used for various purposes. The chip preparation technology is similar to the technology used in the production of particle boards. In a press with special and very expensive tools, the product is given a certain shape. The surface of the parts pressed from the chips can then be lined or finished, after which no further treatment is required. For the manufacture of furniture, for example, profiled and shaped table tops, chair seats, legs, small cabinet products and other structural elements can be made. This method is also used to make cases for televisions and radios.

The use of pressed parts from shavings can significantly save wood, since waste is mostly used as raw material. In addition, the furniture manufacturing process is greatly simplified. Typically, when using pressed parts from chips, many operations associated with their subsequent processing are eliminated. In mass production, the cost of producing chip extruded parts is generally lower than the cost of producing conventional structural components, and it decreases as production volumes increase.

Application and processing of polymer materials

The ever-increasing shortage of wood is forcing the furniture industry to increasingly replace it with various polymer materials.

According to Boehm, in 1980 the ratio of replacement of wood with plastics will be from 1:5 to 1:3. Depending on the type, plastics have a number of advantages over wood: resistance to mechanical, climatic, chemical and thermal loads, the ability to produce profiled moldings, boxes, and beautifully shaped fittings. In addition, they are distinguished by ease of processing and ease of maintenance. The integration of hygienic bread bins, drawers and containers for bulk plastic products into kitchen furniture, guides for sliding doors and drawers increases the consumer value and functional reliability of the furniture. The manufacture of furniture is simplified, since a number of technological operations are eliminated.

For several decades now, polymeric materials have been known as wood gluing materials. Adhesives based on synthetic resins provide high strength and, due to their short setting time, allow for continuous production.

The next area of application of polymers is surface bleaching. Along with coatings and various varnishes based on synthetic resins, high-strength surface coatings are obtained by pressing, in a hot press, paper impregnated with synthetic resins with printed decorative patterns. For this purpose, both high and low pressure presses are used. This technology is widely used in the production of kitchen furniture. In addition to significant savings on veneer, when using decorative film based on impregnated papers, you can easily select surfaces by color and texture. Decorative film is resistant to light, heat and moisture.

Resin-impregnated paper without a pattern printed on it is used as an inner layer under the veneer veneer to level the surface of the particle board. This paper is also used as a primer when applying colored varnish.

Recently, facing materials based on unsaturated polyesters have become increasingly important.

Materials based on unsaturated polyesters make it possible to produce films with both an embossed and non-embossed surface, with a pattern printed on them or in one color, as well as films of various thicknesses and with different degrees of gloss. Such films, using low pressure, can be glued to any surface, even slightly curved ones.

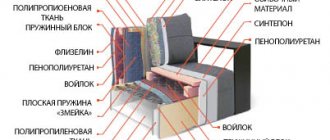

The possibility of combining plastic with wood is to use foam materials as the internal filling of panel elements. Such panels are much lighter than particle boards, but withstand less bending load.

Foam materials made from polyester and polyurethane can be of particular importance in the production of molded parts that cannot be made or can be made with great difficulty from wood. For example, when restoring various products or interior decoration using foam materials, it is possible to completely restore the appearance of the original. Molded parts with appropriate profiles capable of withstanding the appropriate static load will be widely used, which will allow the use of simpler connection principles in design. But research and design are only just beginning in this area.

Taking into account the specific features of polymer materials, it is possible to improve the functional reliability of furniture and improve its quality.

MDF

This material consists of dry wood fibers, which are connected using a special synthetic substance and pressed under high pressure. Cabinets made from MDF will serve their owner for a long time and faithfully. The interior with such a piece of furniture will acquire originality and grace, since the material can be easily given any color, its surface can have an unusual texture and extraordinary patterns.

MDF has the following features:

- ease of care;

- high strength;

- environmental friendliness and safety;

- excellent aesthetic and decorative properties;

- ease of processing;

- pleasant to the touch surface;

- the ability to create furniture of complex design;

- affordable price.

Before you order a wardrobe made of MDF, you must first decide on the color scheme and ornament, since once you are at the manufacturer, you will be surprised by the wide variety of possible furniture design options.

Application of metals

First of all, in order to increase functional reliability, almost all mounting hardware is made of metal. It provides high strength, hardly wears out and is easy to handle.

Wide design possibilities open up with the use of chrome-plated or varnished metal furniture legs, seating furniture frames made of steel profiles and light metals. This eliminates the need for heavily loaded wood joints. In addition, such products are very easy to clean.

In general, for the manufacture of furniture, the main materials used in production are given. Along with the above examples, there are other areas of application of metal parts in the production of furniture products, including fittings.

I also advise you to read the review article – Review of flooring – Linoleum/marmoleum “Forbo”. Good luck with construction and renovation! Write in the comments and subscribe to new articles.