Decorative panels, offered in abundance by the building materials market, can bring any design idea into reality. Materials made from raw materials of natural origin do not pose a threat to health, have reasonable prices, but sometimes have a significant mass and can “eat up” part of the free space. One of the most successful ways for decoration is MDF panels imitating brick.

Natural brick

Decorating with natural bricks is convenient to use in recently constructed buildings, where, in fact, renovations have not yet been carried out. Take note: this option will allow you to save on finishing! And in old houses, the brickwork hidden under a layer of wallpaper can be cleaned, treated and made into a fashionable element of the decor. Newly constructed brick walls will also need treatment. They must be sanded, the seams rubbed, and the surface coated with water-based varnish.

Varieties

Not all types of brick-like materials used for interior wall decoration are the same. They differ in several parameters: material of manufacture, size, installation method and appearance. The most significant items on this list will be the appearance and what the slats are made of. If we talk about materials, then more often than others you can find similar products on sale from:

- Plastic.

- MDF.

At the same time, plastic brick panels can be used not only for interior decoration, but also outside the house, while MDF is used only in residential spaces. There are also sheet imitations of masonry made from chipboard and thin plywood, but they are inferior in performance to the options presented above. However, below are photo examples of such elements. As you can judge from the illustrations, even the external side of such products is less attractive, and their price is higher than that of their PVC or MDF counterparts.

Individual stones made from gypsum cannot generally be classified as sheet-type coverings and can only be considered as an option for the fragmentary design of a small space. This category also includes various imitations of masonry or artificial stone itself, mounted not in large sheets, but from individual components.

Brickwork: why is it fashionable?

The popularity of “brick trends” in design was facilitated by attention to the loft style, which initially used old industrial premises (workshops, factories, workshops, warehouses) as residential ones. Uncovered pipes, plenty of free space and brickwork perfectly preserve the “industrial aesthetics”. Nowadays, a living room in a loft style can be arranged in a regular apartment, using imitation “brick” tiles or clinker as wall cladding.

Another design direction in which brick will look authentic is Gothic. The romance of European medieval castles, knightly tournaments... In this case, brickwork can be used wisely, decorating arches, individual sections of walls, columns, etc. The design is contrasting and original. When rough brickwork is placed next to a luxurious wrought iron bed with a silk throw, it produces an amazing effect!

Brick will become a successful component of modern minimalist interiors. Brick walls can be, for example, pristine white, or gray, or even black. Minimalism is characterized by the creation of contrasting solutions: when the colors of the walls are radically different from the furniture. Nevertheless, in a single ensemble everything looks very harmonious.

Installation specifics

MDF panels for brick walls are mounted in the following ways:

- glue;

- on a frame made of slats.

The use of glue involves surface preparation associated with the removal of old finishing material and contaminants. If there are large defects, the wall is leveled with cement mortar, covered with a primer and dried.

Installation work is carried out from the corner section; the material is adjusted to the required dimensions using a jigsaw.

The adhesive composition is applied to the wall, and the facing panel is pressed. The horizontal and vertical position is checked with a building level.

If installation is carried out with liquid nails, then the fixing material is applied to the reverse side of the facing material in separate dots or zigzags. The panel is then placed in place and pressed tightly against the wall.

As soon as the glue has dried completely, it is necessary to rub the seam areas with the solution.

Now let's look at how MDF wall panels, intended for interior brick finishing, are attached to a frame base. This method is good because it makes it possible to cover utility pipes under the cladding, install an insulating layer, or create additional sound insulation.

Technologically, the process consists of a couple of main stages - the formation of the frame and the installation of panels. The surface of the walls does not require preliminary preparation; the frame performs leveling functions.

Unfortunately, this finishing method requires a lot of time and additional financial costs, and reduces the usable space of the room.

To create a frame, you will need slats with a cross section of 2 by 2 cm. They are easier to install than their metal counterparts, but the base will receive certain features:

- wood should not be used in rooms with high levels of air humidity;

- Each rail is pre-treated with an antiseptic.

Installation of the base is carried out in this way.

The slats are fixed at the ceiling and floor, after which the longitudinal elements are attached, the interval between which is no more than half a meter.

Holes are drilled in the planks in increments of fifty to seventy centimeters, they are applied to the wall and markings are made for mounting sockets for fasteners. All that remains is to drill holes in the wall, install fasteners and secure the frame elements, checking their correct placement with a building level. The free space between the slats is filled with insulating or soundproofing material.

Once the preparation of the frame is completed, they proceed to installation work with decorative MDF panels. First, the starting guide is attached to the wooden slats with a stapler, after which the installation of panels begins, which are fixed to the frame elements with staples. Before installing the penultimate slab, the finishing strip is installed, the last panel is cut to the required dimensions and placed under the finishing profile element.

Finishing work has been completed.

Pros and cons of MDF products

MDF wall panels intended for interior decoration look almost the same as PVC parts. However, they have differences and they are expressed in different sets of advantages and disadvantages. There is no need to list all the already indicated properties, such as visual attractiveness or the ability to choose colors - they are identical to the previous list. The advantages related specifically to MDF are:

- They have good mechanical strength, much higher than the strength of PVC parts.

- The high density of the sheets will allow you to hang light shelves directly on the assembled structure.

- The sound insulation of the room improves, and if necessary, it can be further increased by using additional soundproofing pads in the free part of the structure.

- Installation is carried out in a simple way - using glue or lathing.

- Many consider wood shavings and sawdust, from which the main material of such coatings is made, to be a more environmentally friendly solution than PVC.

However, such decorative wall panels also have some disadvantages. For example, they do not tolerate long-term exposure to moisture and cannot be used outside the living space. Some varieties can be installed in unheated rooms, such as loggias or glazed balconies. The weight of the parts is quite significant and if the elements are large, you may need an assistant to install them. In addition, they cost a little more than plastic products.

Gypsum tile finishing technology

The decor layers are easy to cut; use a regular hacksaw (small teeth). It is better to work with power tools with suitable attachments at medium speeds to avoid cracks.

The low weight of gypsum decor has the advantage of easy installation. You can take cement mortar or construction adhesive for gypsum plasterboard; any composition for tiles is allowed. A “solid” wall will look different with different grout.

Use modern techniques when laying gypsum tiles.

At the end of each row, it is recommended to clean up any installation flaws. For colored tiles, you will have to tint the adhesive with pigment to avoid the need for grouting. High-quality filling of joints in the same tone as the tiles will make the cladding more aesthetically pleasing. The fewer filled voids between the layers, the more convenient it will be to subsequently care for the masonry of torn stone, especially in the kitchen and bathroom.

Always strive for a perfect tile installation.

How to make imitation brick with your own hands using plaster

The most common method of imitation is to apply a building mixture to the surface and create a relief on it. As an example, consider a plaster-based coating. Regular cement compounds will do.

Surface preparation

The wall is cleaned of old finishing and leveled. The bottom layer is left if it holds well and has few defects. The base is primed to improve adhesion to the top layer. It is better to take concrete primer with antiseptic additives.

Marking

Then markings are made. The contours of the masonry are drawn on the wall. The dimensions of the front side are taken arbitrarily, focusing on the area being processed. The tiers must fit without leaving a trace. Their number is calculated by dividing the height of the room by the height of the front side of the brick. The resulting residue is evenly distributed between all rows. You can also increase the height of the seams. In the same way, calculate the length of imaginary products.

Masking tape is cut into strips corresponding to the distance between the bricks and attached to the wall. It forms a line of seams. First, long horizontal stripes are applied along the markings, then short vertical stripes to form a dressing. The tape is not cut strictly along the corner of the wall, but small overlaps are made that go beyond its limits.

Variety of tile designs

For creative interior ideas, you can choose products from a huge range of shades and shapes. White tiles are used for classic, Provence, fusion, modern style, loft. This tone looks great in every room, be it a bedroom or a bathroom. Red-brown tiles are made with the addition of various types of clay. This is a great way to add variety to your design.

Using this material you can decorate a living room or any other living room, and the effect will be pleasant.

Retro style combines well “aged” material with different structures and a slightly loose surface. Such tiles look rich on fireplaces and stoves; they are often used to line shelves, walls and entrance doorways.

If the room has a fireplace, then the tiles are exactly what should frame it and highlight it in the interior.

Material classification

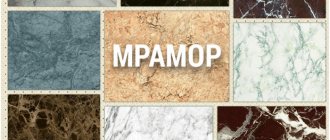

Manufacturers have significantly expanded the range of panels in the form of brickwork used for finishing interior walls. The material differs in texture and color schemes, and has different dimensional values. All this creates the opportunity to translate the most original ideas into reality, use non-standard solutions and finishing techniques.

The most popular panels with imitation brick are the following materials:

- PVC. This material is produced from polyvinyl chloride raw materials, to which special softening components are added. The material is environmentally friendly and lightweight, quickly mounted with special glue. Such panels are used for finishing walls and ceilings;

- MDF. It is based on pure shavings of wood material, which creates good parameters: noise insulation, thermal energy conservation, wear resistance, long service life. They prefer to decorate residential premises with such panels.

In addition to the listed options, there are panel materials made from particle boards, hardboard, plywood sheets and even gypsum. The cost of such panels is low, but the performance characteristics leave much to be desired. Some do not imitate brick stone expressively enough, others do not have proper resistance to moisture or mechanical damage.

This material differs according to the features of installation work:

- the slats are represented by oblong planks that have different widths and grooves for installing the next slab;

- stacked rectangular slabs with easy pattern selection;

- decorative facing material in the form of sheets, characterized by maximum manufacturability.

Panel material is classified according to surface characteristics:

- flat panels imitating modern brick stone;

- relief slabs for wall decoration, reminiscent of ancient stone.

Before you buy this or that type, study the manufacturer’s advice on the features of fastening the material, and check the conditions of its use.