There is so much wallpaper on the market that it is easy to get confused, but one of the most popular options is vinyl embossed wallpaper, which is based on a non-woven backing (less often on paper). Their popularity is not at all accidental, because many of their characteristics are exceptional.

Using modern burgundy wallpaper to create an elegant interior

You can immediately notice the brightness of the image printed on them, the clarity of the texture and the rich color range - and this is just the tip of the iceberg. But let's go in order.

How such wallpapers are made

As you can already understand from the name, these wallpapers have two main layers - on a non-woven base there is a polyvinyl chloride coating (or, more simply, a vinyl coating). The technology used to produce such embossed vinyl wallpaper is not too complicated.

- A layer of specially prepared polyvinyl chloride is applied to the non-woven base.

- The web moves along the conveyor and enters a chamber with high temperature. There the material is heated until it becomes sufficiently plastic.

- The surface of the heated two-layer material is compressed using textured rollers of several different types.

- Cooling occurs. Wallpaper is ready for use.

Interesting embossing and design on the wallpaper

Of course, this is a very simplified manufacturing principle that does not take into account the application of color and image, but the main thing that can be understood from this production technology is that vinyl wallpaper, made by hot stamping and based on a non-woven base, is acquired during the manufacturing process properties of two materials at once. And this is precisely what makes them so popular in the first place.

Varieties

There are several different popular solutions that are produced using the hot stamping method. They (with some exceptions) have fairly similar technical characteristics, but the appearance is usually quite different.

The combination of black and white will create a high-quality interior

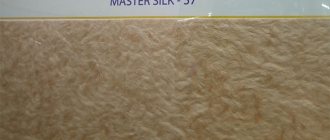

- The first type is silk-screen printing, which produces a coating that resembles silk (although it is not). A special luminescent coating reflects light in a unique way, so when illuminated, a room with such wallpaper looks unique. The color range is quite limited, and the relief is not very textured, but resembles silk.

- The thickest variety is the so-called “compact vinyl”. This same variety is one of the most common. Such vinyl wallpapers weigh a lot, their texture is deep and very embossed, and the palette is the richest; you can find hundreds of shades of colors, which will allow you to ideally choose the optimal solution specifically for your interior. The texture of compact vinyl can be stylized, for example, imitating wood, brick or even leather - therefore, if you want to adhere to a certain direction in interior design, compact vinyl will come in handy.

- Inhibited vinyl is a type of compact vinyl, but processed slightly differently. Chemical embossing is also added to the manufacturing process of the latter, which adds unique characteristics to this coating. Therefore, the price of this variety is one of the highest.

Increased texture of vinyl wallpaper

Advantages and disadvantages

Why is this two-layer hot-stamped non-woven wallpaper so popular? There are a number of characteristic reasons that make buyers choose them:

- Durability. When compared in terms of durability, such wallpapers are inferior only to fiberglass. The warranty on them is very long - about fifteen years. And who wouldn’t want to update their interior at least once within fifteen years?

- Water resistance. Such wallpaper can not only be wiped with a damp sponge, but also confidently washed using various types of detergents. This property of the wallpaper gives you confidence that you will be able to wash off the dirt at any time, be it or any other kind of dirt.

- General resistance to external influences. Various external factors are tolerated very easily by this embossed non-woven wallpaper. They are not afraid of heating from home radiators, they do not deteriorate from exposure to direct rays of the sun, and so on.

- Good heat and sound insulation. If we compare this wallpaper with other materials, then plasterboard has similar characteristics, and this already says a lot.

- Possibility of gluing on uneven surfaces. Embossed vinyl wallpaper based on a non-woven backing is an excellent solution if you need to mask various surface irregularities that may be present on the wall.

- Ease of installation. Since these wallpapers do not stretch, have excellent adhesion properties and fit perfectly on many surfaces, from wood to plaster, they are very easy to install with your own hands.

Floral theme on discreet wallpaper

Each type of coating certainly has its own subtleties and nuances, so it is also important to take into account the disadvantages inherent in this type of wallpaper. In particular, although solutions based on non-woven fabric have better vapor permeability than solutions based on paper, there will still be problems with air transmission, therefore it is recommended to ventilate rooms with such wallpaper especially often.

There will also be a problem if you decide to hang such wallpaper on damp walls. Then the moisture will be trapped, and fungi and mold will develop under the wallpaper. To be on the safe side, it is best to apply a special antifungal antiseptic primer that will protect the coating before wallpapering. Special types of adhesives are also sold that have a similar effect.

The wallpaper collection consists of several options on the same theme

Mechanical stability of the coating. If there is a child or pets in the house, then such a coating may not be optimal in terms of its stability. It is better to replace it with something noticeably more durable.

A few tips that are important to consider when you choose vinyl wallpaper based on non-woven backing.

Using custom brown wallpaper

If you decide to choose a coating stylized as some natural material, do not be afraid to create contrasts. For example, if the decoration of the room is made of wood, then what prevents you from purchasing material that is stylized not like wood, but like brick?

If you want to prefer silk-screen printing, then this, on the one hand, is an extremely good solution, but, on the other hand, it will require almost perfect smoothness of the walls, therefore, if there are even small flaws on them, you will first need to deal with them.

Screen printing is very dependent on the lighting in the room. If the wallpaper is located in a room located on the sunny side, then its palette should be rich and bright; if the light is artificial, then it is better to choose warm and calm tones.

Two types of silk-screen printing from the German factory Erismann, however, the photo cannot appreciate the excellent quality of the wallpaper.

The process of gluing wallpaper on a non-woven basis, made by hot stamping, is almost the same as with any wallpaper, but there are several significant differences when these vinyl ones are glued They are two-layer varieties; they are applied only to the wall.

It should be taken into account that the non-woven material is quite transparent, therefore, if the top layer of vinyl is also not thick enough, then you should first bring the wall surface to a uniform state.

The wallpaper looks a little blurry, but that's the designer's intention.

You can simply paint the wall, or use a special thicker glue. Otherwise, the process is no different - the wallpaper is glued as usual, the glue is applied to the wall surface.

Vinyl wallpaper made on a non-woven base is popular for good reason. Their combination of optimal characteristics and attractive visual presentation makes the choice obvious. You can choose the most suitable types of wallpaper for you and decorate the room to the highest standard.

The emergence of an increasing number of finishing materials serves as a reason for the formation of certain requirements for one or another type of material. Today, preference is given not only to visually attractive, but also to practical and durable coatings. Hot stamped wallpaper for walls successfully combines the above requirements.

Secrets of the popularity of hot stamping

- In terms of durability, such a material can only compete with fiberglass

. Manufacturers provide a guarantee for paper sheets for up to 7 years, for non-woven fabrics for up to 15. Such lining is more likely to become obsolete than to become unusable. - Walls covered with this coating can be safely washed with a regular sponge using household detergents

. An important advantage here is the high resistance to direct sunlight and good tolerance of high temperatures, for example from household radiators. - Such wallpapers are quite accessible for DIY installation; they have high adhesion rates, do not stretch and fit on most traditional surfaces without any problems. They adhere firmly to plaster, concrete or wood.

Advice: before gluing smooth, glossy surfaces, such as smooth concrete, ceramic tiles or stubborn paint. It is better to treat the base with concrete-contact primer. This is especially true for heavy canvases.

- Heavy vinyl wallpaper with a deep texture can successfully hide minor defects or cracks in the base.

- Polyvinyl chloride has a foamed fine-pored soft structure, thanks to which it is a good heat and sound insulator. Thus, the thermal conductivity of this canvas fluctuates within 0.16 W, which is quite consistent with the data for such a coating as drywall.

- Many manufacturers claim that the process of hot stamping of polyvinyl chloride burns off formaldehyde, which is hazardous to health

. We will not claim that this is the pure truth and will leave such assurances to the conscience of the manufacturers. - As for the cost, the price for paper-based silk-screen printing starts at 400 rubles per roll, deep embossing and inhibited vinyl is already estimated at 550 or more. Non-woven wallpaper with hot stamping is considered to be of higher quality and will cost 15–20% more.

Is everything so good

- As you know, 100% universal materials do not exist; hot stamping vinyl also has some disadvantages. This paper-based coating practically does not allow air to pass through. As a result, the room requires more intensive ventilation.

- For the same reason, covering damp walls with such a cloth is highly not recommended, since moisture will be trapped in the wall and fungi and mold will begin to develop under the coating.

Important: non-woven fabric is a thinner material that has better vapor permeability compared to paper. But in any case, even under such a coating it is advisable to apply a primer that has an antiseptic and antifungal effect; sometimes this function can be performed by a special glue.

- Thick fabric, deeply embossed, pleasant and soft to the touch. But precisely for this reason it has very low mechanical stability. If there is an active child growing up in the house, and especially when there are pets, such cladding will not last long.

3499 0 0

Hot-stamped vinyl wallpaper on a non-woven base is an elite roll covering. They come in several types. Let's talk about the advantages of each, consider the disadvantages and methods of application.

Types, properties, characteristics

Structurally, hot wallpaper is a two-component material consisting of vinyl (polyvinyl chloride) and a base. Technologically, the manufacturing process is quite simple, although the possibility of manual production is unrealistic.

Hot-stamped wallpaper for walls is obtained by applying a layer of polyvinyl chloride to a base (base), placed in a high-temperature chamber, where the blanks, or rather the vinyl itself, are heated until it reaches plasticity.

Then the softened surface is exposed to textured rollers of several types, which creates the relief of future wallpaper. Thus, this is a unique variety of well-known vinyl wallpaper, which is what gave the coating its name - hot-stamping vinyl.

Classification by basis

The function of the base can be performed by two materials, which was the reason for the classification.

Vinyl wallpaper hot stamping on paper backing

Advantages: excellent vapor permeability, lightness and low cost. However, they are not able to boast good density, wear resistance, and durability due to the instability of the paper to both mechanical and temperature influences.

Externally, it is almost impossible to distinguish a paper web from a non-woven fabric. Service life – 7 years.

Hot stamping non-woven wallpaper

They have a number of improved characteristics compared to paper wallpaper. The durability of non-woven fabric can be envied by any other type. The main advantage is strength, which prevents the wallpaper from getting wet during finishing work, stretching or tearing .

Hot-stamped non-woven wallpaper is denser and more reliable, which allows it to mask small defects in wall surfaces. Vinyl, on the contrary, will highlight all existing shortcomings.

Most often, hot-stamping non-woven fabric coated with vinyl can be found in an untreated form, that is, they require further independent painting. The useful life is 15 years. Release form: rolls with a width of 1.06 m and a length of 10 m.

By manufacturing method

Embossing used in the production process is performed using three methods, depending on which the wallpaper is divided into separate groups:

Silk-screen canvases

They are distinguished by a flat and smooth decorative surface, which allows them to refract light rays and advantageously emphasize the silkiness and beauty of the wall covering. The effect created by the reflection of light waves is called “silk fabric”.

It is the iridescence that carries the main aesthetic load, and the patterns have a less important function, so most often the patterns are quite small and unobtrusive.

Today, wallpaper is the most popular and widespread finishing material. They are used for finishing walls and ceilings. This material is highly practical, attractive and simple in terms of room decoration. The market offers a huge variety of colors and textures. Wallpaper differs not only in appearance, but also in application methods and performance characteristics.

In this article we will take a closer look at hot stamping wallpaper. Let's look at their pros and cons and analyze customer reviews about them.

Types of wallpaper and methods for gluing them

To understand the gluing technique as much as possible, it is best to start with the characteristics of the canvas itself and move on to further gluing technology. As mentioned above, depending on the chosen canvas, the gluing technique varies, so be careful.

Paper wallpaper

Consist of 2 layers - both paper. Among the features of this type of canvas are:

- possibility of masking irregularities

- strength due to 2 layers of thick paper

- air conductivity

- environmental friendliness - only natural products are used in production

- price - the cost is lower than other alternatives

Among the disadvantages are poor moisture resistance and a short service life - up to 5 years.

You need to select adhesive for paper covering according to the markings on the roll. In most cases, an adhesive mixture for heavy fabrics is suitable.

Before the gluing process itself, you first need to prepare the wall surface. So, the old coating, if any, is removed, unevenness and defects are repaired, fats and acids are cleaned.

Technique for gluing paper sheets

You can glue embossed duplex wallpaper by following these steps:

- The finished wall surface is treated with a primer for better adhesion. For everything to dry and give the best results, wait about a day.

- Measure the lengths of the room to be covered and place them on the rolls. For cut strips, it is advisable to leave 5-6 cm for allowances. Make sure that the patterns and designs match at the joints.

- Prepare the glue as indicated in the instructions and apply markings to the wall on which the strips will be glued.

- Start gluing from the window, removing bubbles (if they have formed) with a spatula as you go. After pasting the strip, remove excess with a special knife.

Also try to apply the recommendations. Thus, work should be carried out at a favorable temperature in the range of 15-22℃.

Close all doors and windows in the room during the procedure. When working with switches and sockets, it is better to de-energize the room.

Hot and chemical stamping vinyl wallpaper

Despite the fact that production methods differ significantly, each of these canvases has qualitative characteristics:

- durability - service life reaches up to 15 years;

- moisture and heat resistance;

- possibility of wet cleaning;

- thermal insulation ability of the coating;

- resistance to direct ultraviolet rays.

Each of these materials also has its own disadvantages; both canvases conduct air poorly, which is why the room should be ventilated frequently. You should also add an advantage to each type, for hot stamping - environmental friendliness (during production, wallpaper heats up and releases some harmful elements), for chemical stamping - resistance to mechanical damage.

The technology for gluing vinyl wallpapers of various types of embossing is identical to paper ones. The only difference is the selection of glue. Based on the markings, select the appropriate glue and do the same as with the paper gluing technique.

Non-woven types of wallpaper

Produced for further coloring. The base of such a fabric consists of cellulose fiber bonded together with polymers. Among the main advantages of this coating are its strength, resistance to combustion, and also:

- good ability to visually mask wall irregularities;

- large width of rolls, due to which simple gluing is ensured;

- possibility of wet cleaning, as well as repeated painting

Among the disadvantages are mainly poor air conductivity and high cost.

Technique for gluing non-woven wallpaper with hot and cold stamping

Regardless of the embossing method, non-woven fabrics are glued in the same way. However, before gluing them, you need to check the level of translucency. So, apply the coating to the wall surface when there is direct sunlight. If the material does not show through, everything is fine, but if flaws are visible, you will have to paint the wall in 1 color tone.

Glue for non-woven fabric should be thick, which remains colorless after drying. The work itself proceeds according to the following scenario:

- Strips are cut to a given length with a “surplus” of 3-6 cm. Make sure that the patterns and designs match.

- The prepared adhesive mixture is applied to the wall.

- The cut fabric is applied to the area treated with glue and pressed.

- When bubbles form, they are removed with a rubber brush.

- The remaining strips are glued end-to-end, observing all patterns and designs.

Vinyl wallpapers

This type of finishing material appeared on the domestic market not so long ago. Only vinyl sheets are available as hot-embossed wallpaper due to their special characteristics and composition. The material has proven itself to be a durable and reliable coating with a huge variety of colors. In this article we will take a closer look at the composition of this type of product.

The coating is actively used to decorate residential premises, work rooms, offices and even various commercial facilities.

Description of technology

Hot stamping is a special technique that is used to create vinyl wallpaper:

- During production, the canvas with the decor applied to it is processed at high temperatures. Special ovens are used for this. Under the influence of heat treatment, the top layer becomes voluminous and plastic.

- After this, the air layer of vinyl goes through the final stage - processing with embossed metal and rubber pressure rollers. It is these tools that create the expressive texture of the finishing material.

Various harmful chemical elements (for example, formaldehyde resins) are released from the vinyl layer under the influence of temperatures. Due to this, the coating is safe to use. We'll talk more about the properties of hot-stamping wallpaper and their classification below.

Fabric composition

This version of the finishing material consists of two elements:

- The basis.

All wallpaper of the above type can have two types of base: paper and non-woven fabric. Depending on this component, the service life and practicality of the canvas changes. Finishing based on non-woven fabric is considered more reliable. Accordingly, the price of such products is higher. - Polyvinyl chloride.

This element creates the final appearance of the wallpaper. It is applied to any of the bases. The amount of component may vary.

Varieties

Experts classify hot stamping models depending on the density of the second layer.

- Heavy vinyl.

The density of this finishing material option is more than 250 g/m². It is characterized by expressive relief, reliability and strength. This type of wallpaper is used when you need to hide unevenness and various defects on the wall. Due to the special properties of the coating, it is not necessary to carefully treat the surface. Externally, designers compare such wallpapers with textured embroidery or crinkled leather.

- Silkscreen printing.

Attractive and light wallpaper. Their density is approximately half that of heavy vinyl. Indicator – 90-130 g/m². When making canvas, special emphasis is placed on the reflective property of the canvas, and not on the textured image. Due to the play of light, the surface looks like natural silk and has a light, pleasant shine. - Compact vinyl.

The density of wallpaper of this class can vary from 150 to 200 g/m². Most models imitate various materials, both natural and artificial (fabrics, brick, wood, stone and many others). You can also find options that simulate large brush strokes. The material is characterized by great thickness, and the texture is particularly embossed. The color of the canvas and the theme of the design can be varied.

Types of non-woven wallpaper

Non-woven wallpaper is available in two types: smooth texture and embossed. If you touch them, they feel like velvet. Structural non-woven coverings can have a continuous relief, a textile surface or a three-dimensional pattern. The coating receives its volume due to a certain embossing technology, for example, hot or chemical with PVC foam.

Material for painting

The most common type of non-woven wallpaper is paintable. These models have an embossed surface and are made in light colors: white, yellowish, light beige. The paint used for them is latex, acrylic or water-dispersion. However, the more layers of paint are applied to the material, the less air exchange will occur in it.

Only after painting with latex paint can the wallpaper be washed. The advantages of this type of wall covering are that the joints of the panels become invisible, and to update the interior, you just need to repaint the wallpaper. This feature allows you to significantly save on repair work. There are several ways to paint non-woven structural wallpaper:

- conventional roller painting;

- structural coatings are painted with a short-pile roller so that only the design is painted and the base remains untouched;

- materials with a vinyl layer can be painted before gluing to the wall, the paint will be absorbed into the non-woven base, and the pattern will remain unchanged;

- Painting the walls before wallpapering will give them a light pastel shade.

- Non-woven coverings are painted only after they have completely dried, not earlier than a day after gluing.

Important! Non-woven wallpaper can be repainted for painting up to 5 times.

Textile wallpaper

Textile wallpaper on a non-woven base looks very elegant and sophisticated in the interior. The base is non-woven fabric, and the textile layer is made of silk, velor, linen or other materials. These wallpapers look very impressive, but are also quite expensive. Let's look at their advantages:

- rich appearance;

- the joints between the canvases are not visible;

- environmental friendliness;

- create additional sound and heat insulation.

The disadvantages of textile wallpaper include the following features: they require regular maintenance, actively accumulate dust, and absorb odors.

Embossed wallpaper

The non-woven base for embossed coverings consists of cellulose fibers that are connected by a polymer. The top layer is made of polyvinyl chloride. Such materials are also called non-woven vinyl. They are usually produced as an embossed coating for painting. They can withstand re-painting several times without losing the quality of the design. Embossed wallpaper has the following advantages:

- fire safety;

- the ability to mask small defects;

- ease of cleaning;

- You can detach the damaged vinyl layer and stick new wallpaper on the bottom one.

Hot stamping vinyl wallpaper

Vinyl coverings have a top decorative layer of polyvinyl chloride. The vinyl surface is resistant to acids, fats and reduces the risk of fire. The production of hot-stamping vinyl wallpaper is quite labor-intensive and consists of the following stages: foamed polyvinyl chloride is applied to the non-woven layer; I pass the coating through a chamber where the PVC becomes soft and plastic; special rollers form the corresponding relief on the surface.

Hot stamping coatings come in three types: silk-screen, which have a smooth and even surface; heavy vinyl is like a thick layer of plaster; flat vinyl, characterized by the imitation of various materials, such as brickwork, stone cladding, wood, etc.

Let's look at the advantages of this type of material:

- long service life;

- resistant to light, heat, water and cleaning agents;

- do not absorb odors;

- have thermal insulation properties;

- are considered the most environmentally friendly of all types of vinyl wallpaper.

The disadvantages of this type of wallpaper include low breathability and high cost.

Important! In a room covered with vinyl wallpaper, air stagnation should not be allowed, as this can lead to increased humidity and the appearance of fungus on the walls. It is advisable to carry out regular ventilation.

Chemical embossed vinyl wallpaper

To obtain chemically embossed vinyl coatings, an inhibitor that suppresses foamed vinyl is applied to individual areas of the PVC-coated canvas. Then the material is heated in the chamber and the layer that has not been treated foams and increases its volume. The result is a very original combination of silk-screen printing and foam vinyl.

Let's look at the advantages of coatings with foamed PVC:

- interesting design;

- resistance to mechanical stress;

- possibility of regular washing;

- long service life - up to 17 years.

The disadvantages of foamed vinyl include the fact that it cannot hide defects on the walls. Therefore, in the process of repair work, you need to take into account that such a coating requires a perfectly smooth wall surface.

Non-woven base

Such wallpapers also have positive and negative sides.

pros

Based on customer reviews and expert opinions, a list of the advantages of hot-stamped wallpaper on a non-woven basis was compiled.

Let's look at the main advantages:

- Safety.

This option is environmentally friendly and completely safe for health. Such wallpaper can be used to decorate houses where allergy sufferers, small children or pets live. - "Breathable" fabrics.

Professionals from the field of decorating residential premises note that the finishing material is highly breathable, which reduces the likelihood of mold forming on the canvas and other unpleasant consequences. - Form.

Wallpaper retains its shape remarkably well for many years after installation. High-quality canvases will serve for a long time, without deformation and attract attention with their rich color.

- Design.

This finishing material provides enormous opportunities for decorating rooms. The varied palette and texture are pleasantly surprising, and the affordable price makes the material accessible to most buyers. - Possibilities for decoration.

Hot stamping fabrics can be used as a base for painting. Paint treatment will not affect the integrity of the finishing material, and the structure will be compacted.

- Versatility. Non-woven fabrics can be safely used for gluing various surfaces. They are perfect for wooden, plasterboard or concrete walls. They can also be used to decorate chipboard walls.

- Dismantling. If you want to update the room, the process of removing old wallpaper will not take much time. The fabric should not be soaked or treated with steam. To remove the old coating, use a regular spatula.

Flaws

Despite a number of advantages, the finishing also has a drawback, although it is not inherent in all canvases.

Regular non-woven fabric without additional coatings and enamel (paints) cannot be washed. The cleaning process can severely damage the product. It is recommended to use only surface treatment with a conventional vacuum cleaner.

Paper based wallpaper

Hot stamped wallpaper on a paper base with two layers has a second name - “duplex”. Material with a relief surface can have a different appearance, from plain canvases with an even color without a pattern to products with an expressive pattern.

Paper-based wallpaper can be used for painting. Next we will look at the advantages of this category of finishing.

Pros:

- Wallpaper creates a comfortable microclimate in the room due to its special structure. This option is ideal for residential premises.

- Masks minor defects on the wall (cracks, abrasions, roughness).

- High-quality duplex wallpaper is much stronger and more reliable than embossed canvases, as well as single-layer paper models.

- During production, virtually no chemicals are used. Thus, it is an environmentally friendly material.

- The cost of wallpaper of this type is affordable for most buyers. This aspect played an important role in the distribution of products. The minimum price of one roll can be about 200 rubles.

Disadvantages of embossed paper-based canvases:

- Cannot be used to decorate kitchens and children's rooms due to low resistance to stains. It is forbidden to wash them.

- The base is subject to various mechanical damages.

- Low service life - about 5 years.

- The standard width of wallpaper per roll is less than a meter (usually 0.53 m), which contributes to a longer pasting process.

- If there is a moisture-resistant coating, it is strongly recommended not to use them if the room has high moisture and damp walls. Otherwise, the paper will become a breeding ground for harmful bacteria, including mold and mildew.

Washable wallpaper and other film materials

Manufacturing plants produce several types of washable wallpaper with a polymer coating. Paper-based wallpapers are metal, silk-screened, vinyl, isofilm, Devilon, foam, leukorten, glass wallpaper. Wallpaper on a fabric basis is polyvinol, artificial leather, vinyl artificial leather, leatherette, texoplen, textvinit. Wallpaper on a non-woven fiber base - pletex. Without a base - plasticized polyvinyl chloride haberdashery film, decorative self-adhesive finishing film and decorative finishing film.

Isoplen is a polyvinyl chloride film on a paper base, which is intended for finishing the internal surfaces of partitions and walls. This material can be washed with water and detergents. Foam film consists of pigments, a stabilizer, a foaming agent, a plasticizer and polyvinyl chloride, applied to paper, followed by heat treatment. This film belongs to the class of combustible materials, which must be taken into account when wallpapering. Polyfiln consists of a paper base, onto which a polyvinyl chloride paste colored in the paste is applied, subjected to firing, during which relief patterns are applied to the base. This film also belongs to the class of combustible materials.

Devilon is a polyvinyl chloride mass applied to a base made of fabric, paper, fiberglass and a foamed polymer backing. The properties of Devilon are similar to those of isoplene, and they also need to be taken into account when gluing wallpaper.

Vinisten can be multi-colored or single-colored, repeating the textures of valuable wood species. This material has high decorative properties.

Leatherette is a cotton fabric with a nitrocellulose coating applied to one or both sides of the fabric. Used as a leather substitute.

Vinyl wallpaper: interior in blue tones

Vinyl leather is a fabric on one side of which a polyvinyl chloride coating with plasticizers and fillers is applied. Vinyl leather is elastic, non-marking, non-sticky, odorless, it is produced in the following types - facing, upholstery and haberdashery. Upholstery vinyl artificial leather is used for finishing sliding partitions and doors.

Baseless polyvinyl chloride decorative film is used for gluing to the internal surfaces of door panels, walls, and built-in furniture. There are two types of this film: PDSO, on the back side of which a non-drying layer of polyisobutylene glue is applied, and PDO, which does not have an adhesive layer. This film is wear-resistant, elastic, has good strength and low water absorption. Most often, the front surface of this film imitates marble, fabric, and valuable wood species. In winter, before gluing the film, it must be kept for 48 hours at a temperature of +18 degrees Celsius.

PVC plasticized haberdashery film is made in different colors based on PVC resin with the addition of three grades of plasticizers - GF, GV and GP.

Linkrust is a roll of wallpaper on which a relief pattern is applied. It is made by applying a plastic mass based on synthetic resin onto a paper base.

Vinyl wallpaper is a two-layer wallpaper that consists of a layer of polyvinyl and a paper base. The outer surface of this wallpaper has a relief. Such wallpapers are easy to clean and wash, they do not fade. They are glued using the technology of wallpapering walls in the bathroom, kitchen, and toilet. When wallpapering, use universal adhesives or special adhesives for heavy wallpaper. Vinyl wallpaper is not used in rooms with poor ventilation.

Foamed vinyl wallpaper is foamed vinyl on a paper backing. These thin wallpapers are available with a pattern or plain colors. Used in non-residential premises that are ventilated. Heavy wallpaper adhesives are used for wallpapering. Foamed wallpaper can be washed; it should not be bent, because this will damage the polyvinyl layer.

Wallpaper with silk-screen printing can be smooth and embossed, they can have a holographic pattern or a shiny surface. This wallpaper is elastic, dense to the touch, and does not fade in the sun. They are glued using the technology of wallpapering walls for finishing the walls of residential and non-residential premises.

Glass wallpaper. This wallpaper is based on fiberglass thread, which is made from environmentally neutral materials - soda, lime, dolomite chips, quartz sand. This wallpaper is produced on a paper backing and has a corrugated surface. Glass wallpaper does not allow rotting, mold and the proliferation of microorganisms. They “breathe”, which helps create a good microclimate in the room, and they can be washed.

Sticking

The wallpapering process is very simple. Wallpaper does not require pre-treatment with adhesives. This simplifies both installation and pattern adjustment.

Hot-stamped vinyl wallpaper is considered elite-class wallpaper when it comes to vinyl coverings. Their peculiarity is a more labor-intensive production process. Thus, the vinyl coating receives an embossing effect during heat treatment. This expensive procedure allows you to obtain a higher density and better composition. This allows you to clean the surface of the wallpaper with detergents after gluing.

Hot-stamped wallpaper can be glued even in new houses, because... Shrinkage is not a problem for such wallpaper.

Hot-stamped wallpaper is highly wear-resistant to various mechanical impacts and those that pets can exert.

The special strength of the material makes it an ideal solution for houses that have just been put into operation. Such wallpaper will not suffer from cracks due to shrinkage of the house.

Gluing technology

Scheme of the sequence of work on wallpapering the ceiling.

Hot-stamped wallpaper should be glued using the same technology that underlies gluing with conventional wallpaper. However, there are still certain features. So, it is not permissible to glue hot-stamped wallpaper by stretching it in width, otherwise you can get gaps between the joints after drying, since the material can stretch and shrink.

Before you start work, you should double-check that all purchased rolls belong to the same batch. Neither the color nor the design should be different.

In order to correctly determine the length of the strip, you need to add about 7 cm to the height of the room. The canvases are cut so that the pattern of adjacent sheets coincides, forming a single element of the pattern. Rolls should be unrolled in one direction, which is indicated on the label, and cutting should be done using 2 or 3 rolls at a time.

Wallpaper can be glued to almost any surface, including drywall, permanently old paint or plaster. If the walls are covered with old wallpaper, they should be thoroughly cleaned. It is recommended to treat cracks and holes using putty and plaster.

Before gluing wallpaper, you should prepare the adhesive mixture. It is recommended to purchase special glue designed for non-woven coatings. In the process of preparing the glue, you should follow the instructions.

The glue is applied directly to the base of the wall using a paint roller. The canvases should be coated so that there are not even small gaps left on them. You also have to make sure that the glue is not applied in too thick a layer. Afterwards, the canvas needs to be folded in half, which will help prevent drying out. In this state, the canvas should be left for about 10 minutes until it “swells.”

Afterwards, the panel must be straightened and glued to the surface. At this stage, it is important to ensure that the canvas does not stretch. Each canvas should be pressed down with a stiff brush or clean rag.

In order to hide the seams, the first strip should be strengthened, starting from the window. The start of work must be accompanied by marking a vertical line using a plumb line or level. The first strip should be glued along the vertical markings. It is recommended to leave a small amount of wallpaper at the bottom and top, which will allow you to even out any unevenness. The next strip should be glued butt to the previous one. A soft brush or rubber-based roller will allow you to smooth the canvas; movements should be directed towards the edges from the middle.

In order to better glue the edges, it is recommended to apply the adhesive mixture in the places where they are connected, then the excess glue must be carefully removed. Until the wallpaper is completely dry, you should maintain a constant temperature in the room, avoiding drafts. If you are gluing wallpaper on problematic walls, you need to place a thin strip of paper under the joints, which will prevent the edges from lagging behind the base of the walls.

Choosing wallpaper is a very important decision in any renovation process. Some people like to glue “forever” and choose materials that can maintain a spectacular appearance for 8-10 years, while others, on the contrary, prefer to change the appearance of the walls every 2-3 years.

The necessary price-quality ratio, interesting color and all kinds of patterns, moisture resistance, the ability to survive scratches, shocks and children's drawings - the ideal wallpaper should meet all these qualities. For this reason, representatives of various segments of the population are increasingly choosing vinyl wallpaper for their walls.

This type of wallpaper has a beautiful, rich pattern.

The main advantages of vinyl wallpaper

Vinyl wallpaper is a special type of wall covering in the form of rolls with a base made of cheap paper or more expensive and prestigious non-woven material. On top is a layer of polyvinyl chloride (popularly called vinyl) of varying thickness, structure and volume.

There are many subtypes in the huge mass of vinyl wall coverings, but they all have common advantages, which are why they are loved by customers.

- Strength. Unlike inexpensive and popular paper wallpaper, vinyl coating has 2 layers: paper/non-woven fabric + vinyl film, so they are much stronger. It is almost impossible to tear a piece of such a roll, for example, when gluing it.

- Durability. Wallpaper with a vinyl layer is the champion in terms of wear resistance: such a coating can stay on the walls for up to 10 years, maintaining the original color and freshness of the paints even with wet cleaning. The only problem is that bright vinyl patterns can simply get boring.

- Moisture resistance. Depending on the type of vinyl wallpaper in the interior, they can be wiped with a wet cloth, thoroughly washed, and even rubbed with a brush or sponge. You just need to select the necessary markings - and the walls will be able to survive cleaning of any intensity.

- Versatility. Perhaps the main advantage of this coating is that vinyl wallpaper in the interior can be chosen to suit any style. The vinyl layer can imitate velvet, fabric, textured plaster, stone, brick, bamboo, wood and other materials. In addition, the choice of colors and all kinds of patterns on vinyl is simply amazing - such a wealth of colors cannot be found among paper, non-woven or textile wallpaper.

This allows you to choose a two-layer wall covering for houses and apartments decorated in any style: strict classics, elegant retro, cozy country, laconic high-tech, industrial loft and others.

Wallpaper with a washable layer can be used to cover a bathroom

Disadvantages of vinyl wallpaper

For all its advantages, building materials made from polyvinyl chloride have a number of disadvantages, which, however, can always be corrected.

- Toxicity. Although a lot of various “test purchases” and studies have already been carried out regarding the dangers of polyvinyl chloride, the debate about whether vinyl wallpaper is harmful does not subside. Indeed, low-quality chemical material, when combined with wallpaper glue, can emit formaldehyde vapor for up to 4 years, but only cheap wallpaper of dubious quality is guilty of this. If you choose the “clothes” for your walls correctly and scrupulously, this disaster can be avoided.

- Air tightness. Another complaint about fashionable wallpaper is its inability to allow air to pass through. Heavy vinyl covers the wall very tightly, leaving it no room to breathe, but it creates a humid environment - a convenient place for the growth of fungi and harmful microorganisms. It is also possible to solve this problem if you choose vinyl wallpaper on a non-woven basis - modern material, unlike paper, allows air to pass through much more freely.

- Problematic repair. If you have no experience in gluing heavy two-layer wallpaper, noticeable difficulties may arise. Thus, vinyl wallpaper on a paper backing can shrink when dried, resulting in noticeable gaps appearing between the glued strips. Vinyl must be glued strictly end-to-end (in no case overlapping!), which does not always work out perfectly, especially with a complex pattern on the canvas and uneven walls. The solution is vinyl wallpaper on a non-woven backing. Such canvases weigh less, are more convenient to hold in your hands during repairs, and the glue needs to be smeared on the wall, not on the roll, which also makes the work process easier.

- Price. The high cost of vinyl rolls is one of the reasons why people choose more affordable paper ones. However, the high price tag is successfully compensated by a long service life and resistance to mechanical stress, dirt and wet cleaning.

Airtightness is a disadvantage of this type of wallpaper. And moisture resistance is a plus

Sound-absorbing wallpaper

Sound-absorbing wallpapers are divided into textile, velor and cork. Textiles consist of natural or artificial fibers on a paper base. Such wallpaper has increased sound insulation, but cannot be washed. Velor wallpaper has a top layer of artificial fibers on a paper base and resembles velvet paper. Cork wallpaper has a layer of cork less than 1 mm thick. This wallpaper is glued using the technology of wallpapering walls without special surface treatment. In the following articles we will talk in detail about all types of wallpaper.

Cork wallpaper absorbs sound well

Prices are indicated without a coefficient depending on the volume and complexity of the work performed. The final cost is determined after a specialist visits the site.

| Name of works | Cost from | Unit change |

| WALLPAPERING WALLS | ||

| Removing old wallpaper | 50 | sq.m. |

| Wall primer (1 layer) | 31 | sq.m. |

| Wallpapering walls (up to 200 rubles per roll) | 150 | sq.m. |

| Wallpapering walls (from 200 rubles per roll) | 200 | sq.m. |

| Pasting walls with combined wallpaper | 134 | sq.m. |

| Installation of curb (without insertion) | 39 | p.m. |

| Installation of curb (with insert) | 60 | p.m. |

| Pasting walls with self-adhesive film | 236 | sq.m. |

| Application of liquid wallpaper (without preparation) | 399 | sq.m. |

Types of vinyl wallpaper

You can find many different classifications of vinyl fabric on the Internet, but there are only 5 main types of such wallpaper.

Structural with a layer of foamed vinyl

This coating has a voluminous loose structure of various colors and patterns, often with sparkles, which are interspersed in the top layer of the lush fabric.

This variety is ideal for rooms with uneven walls. If there are cracks, bulges and small pits on the surface, a volumetric coating will smooth out all the unevenness and create an interesting play of light on the foam surface. This vinyl is also used for gluing surfaces made of wood, plywood, and fiberboard. In addition, fashionable vinyl wallpaper for painting is also a foam material.

Vinyl wallpaper should be painted with caution; first, be sure to check with a specialist in the store whether this type is suitable for painting. For structural vinyl wallpaper, water-based paint and a roller are usually recommended for painting; before the process, a primer in two layers is recommended. The color of the walls can be changed as often as you want until the foam texture on the wallpaper begins to smooth out.

Hot stamping vinyl wallpaper. This group distinguishes between heavy and compact vinyl

Heavy vinyl is the densest canvas available in interesting, deep shades and patterns. Such wallpaper hides wall unevenness well, but it is quite difficult to glue it, and a thick two-layer coating has difficulty allowing air to pass through and can cause fungus on the walls.

Compact vinyl is just a dream for designers: it is the rolls with this canvas that are made to imitate various surfaces: textiles, wood, brick, they are very durable, withstand almost any mechanical impact and retain their impressive appearance for many years.

Sometimes hot-stamped wallpaper includes chemically embossed vinyl. This fabric is particularly resistant to ultraviolet radiation, practically does not fade in direct sunlight and has excellent contact with moisture without damage.

Wallpaper of this type consists, in fact, of three layers

Silkscreen printing is the most beautiful type of vinyl

Such vinyl wallpapers are always on a paper base; silk threads are woven into the top layer, which create a unique noble effect. “Silk” wallpaper can be smooth and embossed, very rich in color, and always looks luxurious and expensive on the walls. These wallpapers are very durable, resistant to water and abrasion, and can retain their bright shade and shine for up to 8-10 years. This coating looks best on walls in corridors, both narrow and wide, bedrooms and large living rooms.

Washable vinyl wallpaper (or polyfoam)

Washable coating is a great way to decorate walls in a kitchen, bathroom or nursery where regular cleaning is required or the walls are often in contact with liquid. Wallpaper can have a smooth or foamed surface; several layers are applied on top of the base: polyvinyl chloride, plasticizers, stabilizers, pigments and other various additives.

Solid or evaporated vinyl

This variety is becoming increasingly popular today - this type of wallpaper vinyl is recognized as hypoallergenic and environmentally friendly. The canvas is based on three layers of paper and evaporated polyvinyl chloride, from which all harmful substances that can subsequently evaporate have been removed.

Wallpaper based on a hard vinyl layer has a quality certificate from the European Independent Environmental Expertise, which means they can be safely used for renovating children's bedrooms and one-room apartments where children live.

Wallpaper with a layer of polyvinyl chloride often has very bright, cheerful shades

Hot stamping wallpaper: what is it and how to use it?

The best option for decorating indoor walls is wallpaper. Among the large number of types, it is worth paying attention to hot stamped wallpaper, as a more modern version of roll wallpaper.

Hot stamped wallpaper is a double-layer vinyl wallpaper.

- The bottom layer of this type of coating is based on paper or non-woven fabric.

- The base of the top is vinyl.

Under the influence of heat treatment, the top layer melts, forming a dense layer of foam. As a result, the material becomes more elastic, and is ready for the last stage - applying a drawing (pattern) using special figured rollers.

Advantages and disadvantages

Let's consider the advantages of this coating.

- Long service life. Paper wallpaper will serve you for at least 8-12 years, its non-woven counterpart - from 20 years.

- Moisture resistance. This wallpaper is “not afraid of moisture.” They can be used both when finishing the kitchen area and the corridor.

- Easy to care for. You can even use a regular kitchen sponge and dishwashing detergent to clean wallpaper. You can use a damp towel to remove any dust accumulated on the drawing.

- Resistant to direct sunlight. Hot stamped wallpaper does not fade or fade in the sun.

- Soundproofing. The non-woven fabric at the base of the covering and the porous shape of the wallpaper conceal sounds.

- Visually straighten crooked walls. A three-dimensional pattern on the wallpaper allows you to hide small unevenness on the wall.

- Quite a varied selection of textures.

Let's also pay attention to the disadvantages:

- Unresistant to mechanical stress. Due to its rough surface, the three-dimensional pattern does not “tolerate” children, animals, or children’s vehicles well.

- Artificial base. Due to the fact that vinyl is not a natural material, its quality characteristics in terms of environmental friendliness and toxicity are inferior to conventional paper wallpaper.

- The walls don't "breathe". The dense layer of vinyl in the base significantly slows down the ventilation of air between the wall and the covering, which is likely to lead to the formation of mold.

- Difficulties with gluing. Thanks to the double layer, hot-stamped wallpaper has a decent weight, which complicates the gluing process.

- Price. The price range for such coverage is quite wide. For really high-quality wallpaper you will have to pay a lot. Please note that you should not save on non-woven fabrics. However, the price of paper wallpaper fluctuates around 500 rubles. per roll.

Types of hot stamping wallpaper

Among the many options for this coating, the following varieties can be distinguished.

- Silkscreen printing . This coating is quite thin, which is explained by a small layer of polyvinyl chloride. Silk-screen printing allows you to create a three-dimensional effect due to silk fabric and shimmer with sparkles. However, it is suitable for a room with perfectly smooth walls.

- Contact vinyl . The exact opposite of silk-screen printing - the vinyl layer is quite thick, which adds significant weight to the coating. Contact vinyl has a relief structure, thanks to which it can imitate brick, fabric, leather and other natural materials.

- Double layer vinyl (heavy vinyl) . Much denser than contact vinyl and has a pronounced pattern.

- Chemical embossing. A special agent, inhibitors, is applied to the vinyl layer along the outline of the pattern, resulting in the formation of a three-dimensional pattern on the wallpaper.

Color palette

Hot stamping wallpaper is rich in textures and patterns. For example, contact vinyl is more often used as an imitation of natural materials - wood, leather, brick.

In turn, among the colors of heavy vinyl, bright shades predominate. Iridescent silk-screen printing is characterized by bed pastel colors, sophisticated patterns, and monograms.

Read about fashion trends in wallpaper for walls here - https://desmyhome.ru/oboi/modnye-oboi-dlja-sten/

Gluing process

In the process of covering walls, it is important to consider several points. Firstly, it is the heavy weight of the wallpaper (in the case of contact vinyl and heavy vinyl). Secondly, you need to glue joint to joint, especially if there is a pattern on the wallpaper.

Please note that the success of covering vinyl wallpaper directly depends on the preliminary preparation of the wall: it must be dry and clean. Before gluing, it is advisable to remove the baseboard, switches and sockets. Always start gluing from the corner. Cut off excess pieces with a well-sharpened tool.

The best manufacturers

One of the leaders in the production of hot-stamped wallpaper is Germany, namely such companies as AS Creation, Rasch and Erismann.

Italy is practically not inferior to its European neighbor - the Zambaiti and Sirpi brands are worthy competitors in the world market.

The Ukrainian factory "Eden" produces vinyl wallpaper of European quality.

Among domestic manufacturers you can find “Erisman”, “Elysium”.

In the interior of different rooms

Hot stamping wallpaper is perfect for the design of any room. For example, pastel colors of silk-screen printing will decorate the bedroom, and patterns and monograms will add tenderness and sophistication to the room. However, dark compact vinyl will provide a more relaxed atmosphere in the room.

The nursery and kitchen will be decorated with bright colors such as yellow, green, pink, turquoise, blue. However, it is better to combine several shades. For the kitchen, you can also use imitation stone or brickwork.

In the living room, the best option would be a predominance of metallic tones, which in turn will give the room a sense of conceptuality and spaciousness. Stylized furniture is an ideal complement.

Learn more about wallpaper for the living room.

Photo collection

A few more gluing options that you can do at home.

Source: https://desmyhome.ru/oboi/oboi-gorjachego-tisnenija-pljusy-i-minusy/