DIY bed repair

Sleeping on a squeaky or wobbly bed is unlikely to be comfortable or comfortable, but you shouldn’t rush to throw away the furniture and replace it with new ones. If desired, the bed can be easily and quickly repaired at home. Repairing will not only help you extend the life of your favorite furniture, it will save your budget - after all, the price of a new bed in a store is a decent amount.

In order to properly and efficiently restore a bed at home, you need to diagnose the type of damage.

In what cases is it necessary to disassemble furniture?

Dismantling of furniture is required in the presence of massive bedroom sets, sliding wardrobes, multi-part shelving, wide three-door wardrobes, and high cabinet construction. Furniture such as double beds and custom designs are always dismantled. The limited staircase openings often make it impossible to load until the furniture is dismantled.

Installation and dismantling of furniture also depends on such parameters as the number of floors of the building, whether it is equipped with an elevator, the amount of furniture to be transported and time constraints. It is mandatory to assemble and disassemble furniture with given dimensions, the transportation of which is carried out in a certain position. First of all, this applies to rare, antique and especially valuable items for which dismantling and disassembling furniture is irrational. This work is extremely necessary, without it it is impossible to perform loading and unloading operations, and it should be trusted exclusively to professionals. Unprofessional disassembly makes the furniture assembly process much more complicated.

Repairing bed slats

If the bed slat (slat) is broken so that it is not possible to seal it, you will need to buy a new element. Bed slats can be found in furniture stores, or you can order them online. Slats are made in single copies in carpentry workshops. Take dimensions from the element and contact a specialist. In just a few minutes they will make you a new slate for your bed. In workshops and stores you can order and buy not only lamellas, but also lath holders. Although these elements are made of durable plastic, they can also break under constant load.

If the entire base fails, you can make a new one using boards or thick plywood.

Features of leg repair

Replacing the legs usually does not pose any problems. A broken leg can be replaced with a new one, and if it is loose, replace and tighten the fasteners.

When replacing the legs, be careful when dismantling the element - it is important not to damage the bed base during the work, replacing which will be a difficult and expensive process.

How to eliminate a squeaking bed?

It is impossible to sleep and get a full night's sleep on a creaky bed. A loud and unpleasant sound can disturb sleep and prevent you from falling asleep quickly. When planning to fix a defect, the first thing you should do is find out exactly what material your furniture is made of. If the structure is made of MDF or chipboard, then the cause of the squeak may be both the fittings and the base boards. Metal beds most often begin to creak at the places where the screws are installed.

To identify the cause of the creaking, the bed structure will have to be completely dismantled and then completely reassembled. During the assembly process, all fasteners are carefully screwed and tightened. If you are not sure that you can disassemble and then correctly assemble the bed, you can try to solve the squeaking problem by treating all joints with different substances: special furniture lubricant, wax-based or silicone-based compounds.

Let's write down the instructions for eliminating bed squeaks step by step:

- First, you should check the tightness of all fixing elements, tighten and strengthen all nuts, bolts, screws and screws. It is also recommended to treat all fittings with a special furniture lubricant.

- Check the mattress: its springs may be squeaking.

- You should also coat all joints in the structure with wax, soap or silicone.

- Pay attention to the slats too. If they are the ones making the creaking noise, you can replace them or change the distance at which they are installed.

- Her legs can also creak in the bed. The creaking of the legs is eliminated by replacing this structural element.

- It is worth checking the evenness of the boards on the base. They should not lie flush against the sides of the structure. If one of the boards creaks, try swapping it with other elements or simply turning the base over.

The cause of the squeak may also be in the fastenings. The easiest way to solve the problem is to replace the old fasteners with new fixing elements. If you do not want to face the problem of squeaking, when buying furniture you should give preference to metal and forged bed models.

Choosing high-quality fasteners for bed repairs

Do you want your bed to serve you flawlessly for many years, and to have to repair it as rarely as possible? Pay careful attention to the correct selection of fasteners. Professionals categorically do not recommend using conventional fasteners - bolts, screws, angles, ties. These types of fixation elements quickly fail. It would be best to choose special types of bed fasteners for repairs in specialized stores. The classic combination of a bolt and a foot can provide excellent fixation of all structural elements.

Please note that not all bed damage can be properly repaired at home. If the base of the furniture has dried out, broken, or you need to renew the varnish coating on the bed, then it is better to entrust this work to professionals. Specialists will help you quickly bring your bed into functional condition, and at the same time, the services will be cheaper than buying new furniture.

Assembling the bed.

It is not enough to transport the bed - it must be assembled in a new place. Gently wipe the parts of the bed from dust, cover the outer sides with furniture polish or varnish if necessary. Assembling the bed is not difficult if you carefully mark the parts when disassembling. If you had to transport your orthopedic bed in cold temperatures, it is best to keep the bed warm before assembling it.

New Level LLC was repeatedly faced with the task of transporting a bed during moves organized by our transport company. Our specialists are familiar with all the nuances of transporting beds. Therefore, if you need to transport a bed inexpensively and efficiently, feel free to contact us for a price estimate and transportation of the bed!

The nuances of repairing a bed at home, step-by-step recommendations

New furniture means comfort, coziness and aesthetic pleasure. But some 7-10 years will pass and your favorite bed or sofa begins to age: the wooden frame cracks in places, the upholstery tears, the foam base sags. Many owners are beginning to look at the bed differently and are thinking about replacing it. Of course, you can buy new furniture, but you can also try to repair it. Repairing beds and sofas helps extend the life of once-loved furniture, as well as save money in the family budget. If you have the desire and a little knowledge, you can easily restore your furniture. First you need to understand what is the cause of the breakdown.

How to restore an old bed with your own hands at home - tips and tricks

Many people got rid of such furniture at one time, but in vain, because it can be brought back to life

Do you have an old bed at home that you are planning to get rid of? Do not rush to replace old furniture with new ones, because it can be restored. I offer simple and effective instructions for restoring beds with your own hands at home. Check out the recommendations in this article and bring time-worn furniture back to life.

What to do if a squeak appears

It is inconvenient to fall asleep on a creaky bed, and it also causes discomfort to those around you. It is impossible to accurately determine the location of this unpleasant sound. It can come from the base or partitions, metal connections of the product.

Basic measures to eliminate squeaking:

- The first step is to determine the material from which the bed frame is made;

- Check all connections. It is necessary to tighten the connecting elements: screws, self-tapping screws, bolts and nuts. For reliability, they can be treated with a special furniture compound. Wax and soap can also serve as a replacement for this composition;

- Carefully inspect the mattress, especially the spring one. The cause of the unpleasant sound may be springs;

- If lamellas are used instead of springs, then broken elements can be easily replaced with new ones;

- Particular attention should be paid to the legs at the base of the bed. Now the choice of legs is huge and choosing the right ones will not be difficult;

- If squeaking is caused by boards lying too close to each other, there are several options for eliminating it - the boards are swapped, the base is turned over, or the contact points are treated with lubricant.

The most successful and 100% way to get rid of squeaking in connecting elements is to replace old fasteners and assemblies with new ones. And it is not necessary to call a specialized company for help for these purposes; you can independently repair the bed at home.

Disassemble the transformable bed

Modern manufacturers of children's furniture amaze with a huge variety of different modifications. Of course, one of the most multifunctional is the transformable bed. Usually it consists of several parts connected to each other. Assembling such a structure is a job for experienced professionals. Dismantling can be done independently:

• how to disassemble a bed consisting of a cabinet, a pendulum and a base, with drawers for linen located in it? Partial dismantling is possible. This option will be required when it is necessary to install the cabinet at the head of the bed and remove the base. Using a set of keys, completing the procedure is not difficult; • transformer options, when the models “hide” inside each other, are more difficult to disassemble. Without the appropriate experience and knowledge, it is better not to do the work on your own. The help of an experienced furniture maker will come in handy; • if the assembly instructions have not been preserved, then do not despair. You can search for a scanned document on websites on the Internet, contact the furniture manufacturer (every self-respecting company has a resource on the World Wide Web).

Restoration of children's upholstered furniture

If a child's bed is broken, it should be repaired immediately, because deformation of the surface of the bed will eventually affect the child's health, posture and well-being.

The places in children's beds that most often fail can be:

- Lifting mechanism in a sliding or built-in bed;

- Wooden partitions of the base and the frame itself due to normal wear and tear of the material or any external mechanical influence;

- Fragile decorative legs installed on furniture under strong impact (intensive play by children, jumping on the bed);

- Poor quality mattresses and product deformation, which negatively affects the child’s health;

- Additional elements: armrests, drawers and sections.

Before you buy new furniture, you should try to fix your old bed. Broken parts can be replaced, and some elements can be fixed yourself. There are several types of lifting devices in furniture design and each has its own characteristics. To repair the bed lift mechanism, you need to have some knowledge and skill, so it is better to entrust this process to a specialist.

The main reasons for the breakdown of children's upholstered furniture:

- Children, unfortunately, often treat furniture carelessly. They perceive it as an element of the game, jumping on it, using it as a trampoline;

- The wood from which the structure of a bed or sofa is made tends to delaminate and dry out. Natural wear and tear of the material leads to various breakdowns of the product;

- Sometimes design flaws lead to premature failure of a furniture sample. This is the incorrect placement of lifting devices or legs at the base of the frame. As a result, the furniture body is affected by significant mechanical loads that break the furniture;

- Poor quality assembly of the structure, when the lifting mechanism is installed in places not provided for in the furniture assembly diagram, due to the incompetence of the worker who performs the operations.

Thanks to the variety of building materials and tools, you can try to repair a bed at home. The result should be some nice furniture. A renovated bed is a new object in the interior of an apartment for little money.

It is worth noting that it is quite difficult to repair beds with built-in lifting mechanisms of complex design. It is recommended to change the side drawers, lamellas or the base itself for an orthopedic mattress. It is better to purchase factory-made walls where lifting devices are installed. The procedure for repairing a children's bed is no different from the step-by-step restoration of large adult bedroom sets.

Restoration

Repairing a bed at home includes several stages:

- The surface where the work is planned to be carried out is covered with film so that dust and dirt do not fall on the floor;

- The furniture is disassembled according to its structural elements: sides, backs, armrests. They are numbered and added up;

- Fastening parts are set aside separately;

- Remove and disassemble upholstery material;

- Inspect the bed frame for cracks and other damage. If any are found, parts of the furniture are replaced;

- They make new upholstery and assemble furniture;

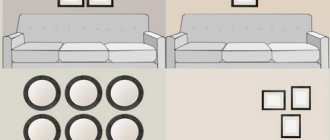

- You can include some decorated elements in the design of the furniture, for example, installing mirrors in frames similar to the decoration of the bed at the headboard on the sides.

Mattress restoration

The main condition for restoring upholstered furniture is a strong frame. The mattress is also one of the structural elements of a soft bed, which requires proper care. One mattress lasts a child for about five years, after which it is better to replace the product with a new one. This is because the baby is growing and gaining weight and height. As a result, the mattress deforms over time and loses its orthopedic properties.

Spring mattresses are very popular, and they still remain in first place in the list in terms of sales. This product has an excellent orthopedic effect and a long service life, which often reaches up to 12-15 years. The service life depends on the use and storage of the product and may differ slightly from the indicated figures. If it breaks down, you don’t have to buy a new mattress in the store; you can try to restore it.

You can repair your bed mattress at home. To do this, you need to stock up on the following tools: a hammer and nails, a furniture stapler and slats, a foam roller and fabric for upholstery.

First, you should make sure about the type of mattress. The first option is intended for use on sleeping beds, the second - on sofas. Their difference lies in the shape of the corners: mattresses in beds have right angles, while sofas have rounded ones. Operations to restore the product are accompanied by the presence of debris and dust. Therefore, it is recommended to carry out work outdoors. If this cannot be done and the mattress repair has to be done within the apartment, then prepare a vacuum cleaner in advance to get rid of excess dust and dirt.

The main steps on how to repair a spring mattress for a bed with your own hands at home:

- The workplace must be prepared in such a way that the mattress can be accessed from all sides. An excellent solution would be to install four stools at the corners of the mattress. The product is placed on stools with the soft side. The paper clips and fastening parts are removed from the base, and the thread is removed;

- Change the flooring and clean the fabric insulating base of the springs from dust. Cut the harness and release each spring;

- Eliminate defects and put the base of the mattress in order: attach torn slats and pieces of fabric in place;

- Install each spring vertically so that it rises 10 centimeters above the level of the frame;

- The old springs are fastened to the slats using belts;

- Once the installation of the springs is complete, they begin to be tied. To do this, nails are driven along the edge of the frame. The upper part is tied using a rope of small diameter. They work in rows - first the transverse rows, then the longitudinal ones. The rope is not pulled too tightly to avoid the springs tightly fitting to each other;

- The rows are tied diagonally and the nails are bent;

- The resulting network with springs is covered with lining material. Usually it is fabric that is clamped by slats on the frame.

How to pack a bed

Much has been said and written about the need to pack furniture during a move. Transportation is a risk, and it can only be minimized by thoughtful insulation of each element of the bed using modern packaging materials.

You will need:

- packaging corrugated cardboard in sheets;

- bubble wrap;

- wide tape;

- any other materials that can be used as covering (polyethylene, multi-layer packaging paper, non-woven fabric).

Laminated, varnished or polished surfaces should be wrapped several times in bubble wrap and secured with tape. The corners and edges of the backs and sides additionally need to be protected with cardboard. If the base is a frame spring mattress, carefully wrap it in paper and cling film to protect it from dust and moisture. Don't skimp on packaging: restoring and cleaning a bed after an unsuccessful shipment will cost much more.

The fasteners should be placed together in a plastic container with a screw-on lid - this way you can be sure that you will not lose them along the way.

Don’t know how to pack a bed, but don’t have time to study other people’s experiences? Contact us! We will help protect your furniture from any accidents during the move.

Back to Contents

Basic Rules

Repairing broken bed elements does not require such a careful approach as, for example, repairing mirrors, but it still cannot be done without preliminary preparation. It is also necessary to select materials and tools, find out the cause and type of damage. In addition, it is important to follow certain rules for carrying out work:

- before screwing in the screws, holes are specially drilled for them, the depth of which is 2/3 of the length of the fastening element, and the diameter is 3/4 of its diameter;

- before screwing in the screws, the prepared hole is filled with PVA glue or a polymer-based emulsion;

- It is better to choose nails with a ring notch;

- It is also recommended to coat the joints of parts with glue;

- nails are hammered only some time after gluing the parts (12–16 hours).

Failure options and fixes

To repair a bed at home, you must first find out the cause and type of damage. Most often it is necessary to restore the legs, slats, frame of the product, as well as the spring mattress. The technology for carrying out work is different in each case.

Leg repair

If the entire structure is attached to the legs, then bed repairs must be carried out very carefully. When parts become loose, the fasteners must be tightened. If they break, it is better to completely replace them. To do this, the nuts are unscrewed, damaged components are removed, and others are installed in their place and clamped with fasteners. Ready-made parts can be purchased or made independently. If the master is a beginner, then the first option is preferable.

Most often, children's beds have to be repaired. The reason is that this type of furniture for a child is not only a piece of recreation. He can play on it, jump, do what he likes. This often causes damage to the lamella. If the damage is minor, then it is enough to fix the element with glue. Otherwise, the part is replaced. Moreover, now you can purchase not only the lamella itself, but also its holders, which are most often damaged.

If the damage is minor, then it is enough to fix the element with glue

In the event of a serious breakdown, the failed part will have to be replaced.

Frame frame

Although this part does not experience maximum stress, failure of the bed frame is common if it lasts more than 3-4 years. The problem may be as follows: the crossbars that connect the backrests pop out. The reason for this is the wear of the coupling bolt. To correct the situation, you need to drill several holes in the end of the cross member. After this, insert guide pins into the outer holes, and a tightening bolt into the middle one.

Another type of failure is the loss of the metal fitting connecting the front backrest and the crossbar of the furniture. To solve the problem, you should simply fix the element in its place. To do this, wind the thread around the foot in the opposite direction to the twist. The diameter of the product should be slightly larger than the size of the loosened hole.

Before fixing the part, the hole is coated with glue, and then the component is installed in place. A screw or self-tapping screw is also screwed into the back of the furniture, securing the footing on the back side. Once it has hardened, the bed can be used.

After 3-4 years of use of the product, the tightening bolt may fail, which will lead to breakage of the bed frame

If the cause of the breakdown is associated with a fallen out fitting, you should fix the element in place by winding a thread around it and lubricating the loose hole with glue

Lifting mechanism

Different types of lifting mechanisms are installed in beds, therefore their repair schemes are not the same. Before starting work, the type of structure is determined and a visual inspection is performed. The algorithm for repairing the bed lifting mechanism is as follows:

- First, the structure must be removed and disassembled. It is advisable to photograph the entire process or write down the sequence of unscrewing the parts so as not to get confused during assembly.

- Conduct a visual inspection of the mechanism to identify broken parts.

- Replace damaged components and assemble the structure.

- Place the product in place.

To prevent the lifting mechanism from breaking for a long time, it must be periodically lubricated. Thanks to this, the friction of the fragments, as well as their wear, will be reduced. In addition, the protective oil film will prevent rusting and corrosion processes.

To ensure that the lifting mechanism lasts as long as possible, it must be lubricated periodically.

Benefits of DIY restoration

An alternative to restoration - artificial aging of furniture

- Saving money . A good modern bed costs a lot of money, so why not restore old furniture, which in the end will be no worse.

- Old furniture is better quality than modern furniture . Until the end of the eighties, Soviet beds were made to last and last, while modern products will last no more than ten years without repair.

- Fashionable retro ambiance element . Retro is in fashion, and therefore, by restoring an old bed, you will get a unique element of the surroundings for a very small amount of money.

- Old furniture can be modernized . With the right approach to restoration, a bed can not only be restored to its original appearance, but also modernized. As a result, furniture that was otherwise thrown away will be relevant when arranging modern interiors.

- Gaining valuable experience . If the bed restoration is successful, you will gain valuable experience that will be useful when restoring other furniture in the house.

Where to begin

Most iron beds are in excellent condition and for their restoration it is enough to select a mesh of the appropriate size

No matter what you decide to restore, you need to start by identifying and assessing the damage that will have to be repaired during the restoration.

If the wear of the bed is insignificant, you can do without disassembling and limit yourself to eliminating cosmetic defects on the back and foot. If there is a lot of damage, the bed will have to be disassembled into individual structural elements, cleaned of accumulated dirt, after which it will be possible to identify all the defects and decide on their elimination.

When is restoration appropriate and when is it not? Any furniture can be restored, even in very poor condition. But you need to understand that the worse the condition of the furniture, the more time, effort and money will have to be spent on restoring it.

Chipboard is a short-lived material, but if desired, it can be updated

An important point is the material from which the bed is made. The easiest way to restore metal products is to simply clean off the rust and oxides, after which you can start painting. Furniture made from chipboard is the most difficult to restore. After more than 10 years of use, particle board loses its former strength, and therefore I do not recommend restoring old broken chipboard beds.

The most popular option is restoring wooden beds. Such furniture, being made in the 50-60s of the last century, is now distinguished by enviable durability and all you have to do is repair chips, cracks and abrasions.

Features of partial restoration

Attention. When repairing the frame, we use dry wood, which does not deform or crack during the drying process.

Required tools and materials

During the restoration you will have to do a lot of sanding, and therefore you cannot do without a sander

Furniture restoration requires a variety of tools, including:

- Devices for disassembling cabinet furniture - hex keys for confirmations, spanners for bolted connections, screwdrivers for self-tapping screws and screws.

- Equipment for roughing and grinding the surface - an industrial hair dryer for softening the paint, a sanding machine with a set of sandpaper of different grain sizes.

- Painting tools - brushes, rollers and sprayers for applying paint and varnish materials, as well as spatulas and sandpaper for applying a leveling layer of putty.

Wood putty is an effective remedy for removing deep dents and scratches.

In addition to the tool you will need:

- Paints and varnishes (paints and varnishes) - including varnishes, paints and stains.

- Primers and impregnations - these materials reduce the absorbency of wood, increasing adhesion to coatings.

- Putties - used to level the relief on wood.

- Oil and wax impregnations and mastics - to mask cosmetic defects of the old coating.

Brief characteristics of restoration compositions

Varnishes vary in texture and come in glossy, semi-gloss and matte. Also, varnishes can be colored or colorless.

If wood is treated with stain or other coloring compounds, it is preferable to use colorless varnish.

The use of varnish over paints and enamels is due not so much to the decorative as to the protective effect.

The use of oil impregnations is allowed only on solid wood surfaces.

Methods for eliminating minor defects

Mix 1 tablespoon of vinegar and 2 tablespoons of unrefined sunflower oil in a small bowl until an emulsion is obtained. Next, dip a thick cloth in the composition and oil the abrasions. As the composition is absorbed, apply it again.

As a rule, for cosmetic masking of abrasions, three layers of the product will be sufficient, with a break for the previously applied layer to dry. To mask scuffs on dark furniture, it is better to use olive or castor oil instead of sunflower oil.

On the market and in auto parts stores you can purchase a repair marker that masks scratches on the paintwork. This option can also be used for cosmetic restoration of furniture.

Scratches are degreased and rubbed with soft wax. The applied layer of wax is softened with a hairdryer.

After the softened wax has cooled, polish the surface with a soft cloth and no traces of repair will be noticeable.

Varnish layer renewal technology

Let's look at the instructions for updating the varnish layer using the example of restoring the headboard of a bed.

After the putty has dried, the headboard is sanded down to wood using 200 and then 80 sandpaper.

We sand the wood with a sander or float. If you hold the surface with your hand, it will not work.

After the wood has been sanded, remove the dust with a solvent.

The varnish is applied in several layers with a break for the previous layer to dry. After this, the surface can be polished.

If you prefer a glossy surface, as in the photo, use a glossy varnish. If gloss is not needed, use varnish with a matte texture.

Finishing the product - decoration

Decoupage consists of making decorative appliqués that are cut out from special napkins and glued on top of certain areas of furniture.

Various methods are suitable for artificial aging, including applying and then sanding paint, brushing wood (combing out soft fibers), etc.

If earlier the thinnest gold foil was used for gilding, today there is no need for such expenses. Inexpensive “golden” paint can be bought in a can at any construction market.

For a better effect, gilding can be used not only in decorating the bed, but also when decorating other furnishings in the room.

You can cover the headboard, footboard and sides, as shown in the photo. Under the leather upholstery we place a foam filler.

How to eliminate a squeak

It's uncomfortable to fall asleep on a bed that creaks. In addition, this unpleasant sound can irritate others. In houses with thin walls, even neighbors can hear it. To get rid of a problem, you need to determine the cause of its occurrence. Depending on the type of breakdown, eliminating squeaks in beds with your own hands is done as follows:

- The frame of the product is carefully inspected beforehand. Pay attention to all connecting elements. If they are loose, they are tightened. Additionally, screws and bolts are lubricated with a furniture composition based on wax and soap. Excess gaps in the wooden frame of the bed can be eliminated using a cork seal. Additionally, it is recommended to use furniture glue.

- Often the cause of squeaking is the springs of the mattress. Due to the constant load, they become unbalanced. You can correct the situation by turning the product over. If this does not help, then you need to replace the springs and purchase a new mattress. It happens that the product rubs against the frame of the bed and a squeak appears. The defect can be eliminated by preventing contact of the mattress with the wood.

- An unpleasant sound is often produced by broken slats. If they cannot be repaired, then it is better to replace the incorrectly functioning elements.

- It is also necessary to slightly rock the legs of the bed. In this case, creaking occurs in the area where the supports connect to the frame.

- The cause of the unpleasant sound is defects in the supporting structure - cracks. If they are numerous, then it is better to replace the housing. Single damage is filled with furniture glue and reinforced with a metal plate.

- The creaking occurs due to the fact that the bed is on an uneven floor. In this case, it is better to move the furniture to another place or replace the floorboards.

The simplest and most reliable way to eliminate squeaking is to update old parts. It is important to pay attention to the lifting mechanism.

The cause of a squeaking bed can be loose connecting elements.

Due to the constant load, the mattress springs become unbalanced. To eliminate the squeak, it is recommended to turn the product over or purchase a new one.

Broken lamellas that produce an unpleasant sound must be replaced

Creaking may occur in the area where the supports connect to the frame.

A crack in the frame can be filled with furniture glue and reinforced with a metal plate

Wooden bed for a beginner

Are you tired of your old bed?

Many of us still continue to use old Soviet furniture in our apartments, which were once created for the needs of the working class returning home to spend the night. It was never distinguished by special aesthetics or a scrupulous selection of materials, and therefore had special value. So if you're still sleeping on an old Soviet bed, you know how to end it. Pay attention to the plans for making simple platform beds from natural wood, which even a beginner can handle assembling. An author from the USA made this bed for his daughter for only $50. This is a negligible amount for residents of America, since finished furniture from a furniture showroom will cost several hundred. Moreover, the bed is made of natural wood, and this is real luxury by modern standards.

In order to make a wooden bed at home, you will need fairly modest equipment, metal consumables, such as furniture screws, and wooden boards, bars and slats. But more about this:

Materials:

— wooden blocks with a cross section of 70 x 50 or 75 x 50 mm for making the frame; — support slats for the flooring under the mattress or lamellas with a thickness of at least 25 mm; - slats or thin boards for making a base for a mattress; - planed boards for a wooden headboard of the same thickness; - decorative slats for framing the headboard according to the thickness of the boards used; — decorative protective oil-toner or primer-toner for wood processing; - white paint for decorating the headboard; - furniture screws; - metal corners to strengthen the frame if desired; - glue for woodworking.

Tools:

— a circular saw or miter saw (you can use a sharp wood saw with a fine tooth); - electric drill; - screwdriver; — a grinder, if necessary; - soft cloth for oiling wood or paint brushes for priming and drawing the design of the headboard; - construction tape and square; - pencil.

Step one: preparing lumber for work

If you manage to purchase properly processed boards, the entire process of making a bed will be simplified significantly. Not to mention the list of tools and equipment you will need.

This means that the boards must be carefully and evenly planed, have a smooth surface and a suitable degree of drying. Before ordering material delivery, make sure that the bars and boards are the same thickness. In this case, the error will not have fatal consequences, except, perhaps, for the untidy appearance of the finished structure.

You don’t have to put forward such requirements for slats. All that is important to you is the flat plane of one of the edges, on which the lamellas or boards under the mattress will be fixed. However, it is also advisable to treat them with protective compounds, and if the surface of the wood turns out to be loose and uneven, their consumption increases significantly. But this is sometimes the most expensive item of expenditure.

Step two: preparation for assembly

Assembling a wooden bed frame with your own hands is not such a difficult task. The main thing is to stick to the sequence. The accuracy of the markings and high-quality cutting are also of great importance.

The most convenient tool for cutting lumber for furniture making is, of course, a miter saw. It allows you to maintain a precise, even angle, so that all parts of the structure fit evenly and tightly to each other. However, until recently, a miter saw was an unaffordable luxury, and everyone did without it.

You can just as easily use a circular saw or a hand saw for wood. And in order for the corners to be even, buy and use a construction square, which allows you to mark bevels at a certain angle, including at an angle of 90°.

The author used simple butt-to-butt pocket joints. This allows you to avoid making complex grooves, which are so intimidating for novice home craftsmen. Pocket joints are joints made using furniture screws or wood screws, twisted at an angle so that the head is recessed into the wood.

All holes are pre-drilled using an electric drill. They can later be filled with epoxy sealant or wood putty. However, it is better to place them in such a way that the connections are invisible to the eye.

Step three: assembling the frame of a wooden bed

The author advises starting assembling the frame by making the front and back panels. Both panels are identical and consist of six parts: four frame parts and two braces, which also double as decor.

All parts are connected end to end, so pay special attention to marking and fitting. Start by assembling the frame using screws and glue. Saw off the braces at the desired angle and install in place.

Screw the longitudinal bars of the bed frame. Fix support slats or bars on them for laying slats or boards under the mattress. At this stage, you can strengthen the frame using metal corners and connectors. It all depends on what load is expected during operation. However, first it is necessary to complete all wood processing work. So feel free to move on to the next step.

If desired, you can also make a hanging panel - the head of the bed. It is assembled from planed boards and framed with slats. The dimensions of the panel are arbitrary and depend on the size of the bed itself. In any case, it perfectly complements the bed and will help you fit it into the interior.

Step four: protection and decorative processing of wood

The author used a toner primer that perfectly tints natural wood, imitating valuable wood species, but at the same time preserving its natural texture. It also protects the wood from moisture, dust and the formation of fungi.

You can also use a decorative toner oil or varnish with a toning effect. All these compounds are new generation products. They give an interesting effect, slightly different, but generally similar. The most durable coating of all of the above is varnish. It also protects the tree from minor mechanical damage.

Apply the coating of your choice in several layers according to the instructions. Give each new layer time to dry.

Step Five: Finishing Touches

Install slats or treated boards to form a base for the mattress. Also screw in metal fittings, if provided for in the design.

Place a level wooden headboard on the wall. The author used a laser level, but you can use a regular one. Place the mattress on the base.

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Troubleshooting spring mattress problems

The mattress is an essential part of the bed design that provides comfort. This item requires proper care. It is better to change it every 5 years, but if this is not possible, then it is recommended to correct the shortcomings that appear yourself. Standard beds use a spring mattress that deforms over time.

For repair work you will need the following materials and tools:

- nails with a hammer;

- slats;

- upholstery fabric;

- furniture stapler;

- foam;

- spare springs.

Repairing a spring mattress involves the following steps:

- Preparation of the workplace. The product must be placed so that it can be approached from all sides. It is better to place it on stools placed in the corners. The base is freed from fasteners and paper clips.

- Replacement of internal parts. The fabric that insulates the springs is cleaned of dust. The old element binding is removed.

- Elimination of defects on the base of the mattress. The torn parts are sewn back into place.

- Restoration of springs. Each element must stand strictly vertically and rise 10 cm above the frame level. To fasten the parts, slats and belts are used.

- Strapping. This process requires a responsible approach. It is necessary to hammer nails along the edges of the frame. A thin rope is used to tie the top of the springs. First, the rows are processed across, and then along. Do not pull the string too tightly so that the springs maintain a vertical position and do not touch each other. Additionally, the strapping is done diagonally, after which the nails are bent.

- Finishing. A lining is placed on the resulting mesh, which is fixed to the frame with slats.

How to reupholster the base of a bed with your own hands: master class + tricks and tips

If the base of your bed is upholstered in fabric, and the fabric is no longer as fresh as you would like, here is a master class on how to make new upholstery.

This method is suitable if the upholstery of the bed base is worn out, dirty, or you just want to change it. For example, in our case, for a small bedroom, we wanted the furniture in it to be light. Therefore, it was decided to change the dark fabric upholstery to a new, light pink color.

All work was completed in 1 day. Here the reupholstery took a little longer than it might have, as the original dark upholstery could show through the new light pink fabric, and the base was first reupholstered with an additional layer of white fabric. If your fabric for upholstery is thick enough, you can skip the “lining” step.

How to sew a sofa cover: 3 master classes

You will need:

— fabric for reupholstery;

- if necessary - fabric for an additional “lining” layer;

- tools to disassemble and then assemble the bed base;

- fabric scissors;

- sewing machine and threads;

- furniture stapler and staples;

- if necessary - small nails and a hammer.

Bed valance skirt: master class

Step 1

Disassemble the bed, remove the legs and other parts that will interfere with the upholstery. To avoid confusion later during assembly, you can mark the right/left parts and write down on a piece of paper at what distance from the edges of the parts the fastening points are located (holes for screws, etc.).

Step 2

First - the headboard, the “lining” layer. Take a piece of fabric sufficient to wrap the part with a large margin (minimum 20-30 cm, the excess can then be trimmed). Wrap the headboard with fabric, inside out. At the corners, secure the folds with pins. Then remove the fabric, stitch the corners and trim off the excess.

Turn the part for the headboard upholstery right side out and place it on the headboard. Wrap the edges of the fabric, pull them quite tightly and secure with a stapler. You can start from the middle of each side, gradually moving to the edges. Ideally, two people work: one stretches and holds the fabric, the second secures the fabric with a stapler.

Step 3

Now - the outer layer of fabric. Here the excess fabric is simply neatly folded into folds, and the folds are secured with a stapler. You can do the same as in the step above, sewing up the corners and cutting off the excess.

Step 4

When finished, return the headboard fastening elements to their place.

If you use two layers of fabric, as in our case, you can, after the first layer is ready, find, by checking the notes, places for fastenings, and mark them by screwing in and out the screws. It will be easier to find these holes later.

Step 5

Tighten the side and end parts according to the same principle. The corners on these bed parts can simply be cut off (see top photo). In places that are difficult to reach/inconvenient to work with a stapler, you can use small nails and a hammer.

Step 6

All that remains is to return the parts to their place and assemble the bed.

Source: burdastyle.ru

What is a lamella

Before you begin, you need to familiarize yourself with the description of the features of the lamellas in more detail. Lamels are wooden structures that have a curved shape. Their characteristic features include a high level of elasticity and elasticity. It is thanks to these features that the mattress can be securely fixed.

Such wood products are laid out at a distance of 2-5 centimeters. This allows slatted beds to be used by both thin and overweight people. The thickness of one plank reaches ten millimeters, and the width does not exceed thirty. However, cheap beds can use boards 4-5 millimeters thick.

Main causes of breakdowns

Sometimes people find that the board in their bed is broken. There are several main reasons why a wooden plank can break:

- Exceeding permissible loads. Wooden slats have certain load limits that should not be exceeded. However, some people still overload them, which later leads to breakdowns. Therefore, it is recommended to familiarize yourself with the permissible loads of the slatted bed in advance.

- Marriage. Sometimes manufacturers install low-quality products made from defective wood. This often happens when using overdried wood, which quickly breaks even under light loads.

- Long-term operation. Slats may break if used for more than ten years.

How to choose new ones

Sometimes it is not possible to repair old products and you have to replace them with new ones. Before purchasing new boards, you will have to understand the specifics of the purchase.

When making sofa grilles, lamellas are used, which may differ in size. Therefore, before purchasing, you should familiarize yourself with the main types of such products:

- Wide. These designs are purchased if you need to replace the slats on large sofas where bonnells with springs are installed. The width of such boards does not exceed seven centimeters.

- Narrow. They are considered a universal material, as they are suitable for any mattress. Experts advise buying narrow slats for beds that have spring mattresses. This will increase the strength of the structure. The width of narrow lamella materials is 4-5 millimeters. The thickness of such planks is small and reaches only three millimeters.

Quantity

Having decided on the dimensions, you need to figure out the optimal number of slats. Some people don't know how many boards they need to buy to strengthen the base of the bed.

Experts recommend buying a lot of lamellas, since the strength of the product depends on this.

To determine the required number of slats, take into account the dimensions of the bed. For example, for double structures, at least thirty planks are purchased. For single beds, 15-20 pieces are enough. However, some manufacturers install more than thirty slats to make the sofa more elastic and resistant to stress.

Most often, slats for sofas are made of wood. It is used to make adhesive plywood, which is laid in several layers to create a more durable surface. Products made from plywood are characterized by good elasticity and elasticity. The lamellas can also be made from the following materials:

- Birch. Budget products are made from young birch trees. Such structures are not very durable and therefore are not recommended to be used.

- Beech. To make more reliable bed bases, beech is often used. This wood is flexible and highly durable.

How to repair and replace slats

At the initial stage of repair, it is necessary to get rid of damaged planks. They are carefully removed from the groove, moved to the side and removed from the structure. Some types of lamellas are attached using special holders. In this case, you will have to use pliers or a screwdriver.

Some people use a hammer, but it is not recommended to use it so as not to accidentally damage the structure.

If the slats are broken in the central part of the bed, you can swap them with the outer slats. This is done when one or two planks are broken. If more lamellas are broken, you will have to buy new ones. In this case, it is recommended to buy the same products as before. The purchased products are carefully attached to the bed using clamps. After installation, you need to check the reliability of the fastening and make sure that the slats are not loose.

How to repair a lifting mechanism with your own hands

Sometimes the bed lifting mechanism, which is responsible for transforming the structure, breaks along with the slats. The following signs indicate a breakdown:

- spontaneous lowering of the orthopedic base;

- jamming of the mechanism when lifting or lowering the structure;

- creaking and other extraneous sounds that occur during operation.

If one of the listed symptoms appears, it is necessary to disassemble the lifting mechanism. To do this, the mattress is removed from the bed, after which its base is unscrewed. Then the fasteners are unscrewed, with the help of which the mechanism is screwed to the structure. It is difficult to repair such a product yourself and therefore it is better to take it to a specialist who professionally repairs furniture.

Methods for restoring an old bed

If the bed is too old, you can restore it and make it look like new furniture. During the restoration process, it is necessary to carefully inspect the structure and identify parts that require replacement. Most often, the springs and mattress are changed during restoration. Sometimes people decide to replace worn side panels. To do this, you will have to purchase new panels that are suitable for the restored sofa. If the side parts are not very worn, you can sand them and varnish them. It is recommended to use varnish mixtures that have a mahogany tint.

Packing the bed.

In most cases, the packaging of the bed reliably protects it from scratches and damage. However, if it is necessary to transport the bed in dangerous conditions (broken roads, numerous overloads, unreliable body), it makes sense to polish the bed with protective and water-repellent agents. If you have entrusted the bed to a reliable transport vehicle, there is no need for these measures.

To transport the bed disassembled, the smooth and polished panels must be securely packed to protect them from dust, dirt and scratches. At the same time, the packaging should not be slippery, so as not to make moving the bed difficult. The ideal option is bubble wrap, foamed polyethylene; for reliability, you should first tightly wrap the panels with corrugated cardboard.

If there are no special complaints about its appearance (for example, old furniture), you can transport a bed without packaging, or with minimal protection from dirt. But transportation of a new, expensive bed must include mandatory packaging.