Types of log tables

Furniture made from logs will ideally fit into the design of any garden plot of a country house. The table can be placed on the veranda of the house, under a canopy or in a gazebo. It will look cozy against the background of a log house.

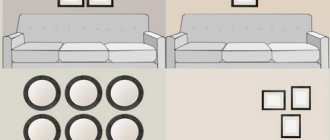

Based on the shape of the tabletop, furniture can be divided into several types:

- rectangular structures are very convenient and functional, as a rule, they have enough area to freely accommodate all family members;

- furniture with rounded edges will suit the original interior of a room with interior decoration made of natural wood;

- a table made of rounded square logs is perfect for a small gazebo.

The size of the table will depend on its location and the maximum number of users. The main feature of the design is the original shape of the legs. They are usually made from halves or whole logs. Furniture is made from wood of various species. Such material remains after the construction of a private house, garden buildings, and auxiliary buildings.

Photo

Summer residents and owners of private houses know firsthand how great it is to enjoy the singing of birds, the chirping of crickets, or just a conversation with family and friends at a beautiful table in a cozy outdoor setting. And what could be more peaceful and inviting than a romantic dinner with your loved one or just a cup of tea alone in this atmosphere?!..

However, unfortunately, not all owners of such potentially peaceful gazebos and places to relax can boast of a comfortable and durable table that harmoniously complements the necessary furnishings: some simply do not have the desire or time to buy one, while others are limited in money, Therefore, he doesn’t even think about purchasing a good table. But there is always a way out!

Do you still have logs from the gazebo? Then the issue is resolved! Make a table out of logs with your own hands.

So, let's get ready.

Create a drawing

Before you begin installing the table, you need to make a drawing on a sheet of paper. Here the dimensions of the structure are plotted and a log layout diagram is selected. You can make a drawing on paper in several projections.

A three-dimensional drawing made in computer programs is considered more convenient. You can examine a piece of furniture from all sides, select dimensions, and also determine how a particular type of wood will look. The table, which is designed with a special program, can be adjusted to suit the specific interior of the room.

Preparation of logs

At the initial stage of making a table from logs with your own hands, you will need to prepare raw materials. All products are selected in accordance with the dimensions indicated in the drawing. You can make furniture from materials without preliminary surface preparation, but it will look rough.

To make a beautiful wooden table, you will have to work hard and spend a lot of time preparing the raw material. All bark is removed from the wood using an ax or a hammer with a chisel. You need to act with special care so that there are no chips or cracks left on the surface of the logs; it should be even and smooth.

Important! If it is necessary to make a tabletop from log halves, it is recommended to use the services of sawmills. You can make the cut yourself using a chainsaw, but it will take longer to prepare the surface.

To connect the workpieces into a single structure, special grooves are made on each of the parts. You can do without this. In this case, a perfectly flat surface is made at the joints of the parts using a plane, but the width of the plane should not exceed 3 centimeters.

To create beautifully shaped furniture for a summer house, the edges of the log (top, bottom) are cut at an angle of 45 degrees. All end parts are cleaned with a file and then with sandpaper until a completely flat surface is obtained. Then they take a drill with a drill that matches the diameter of the reinforcement used and drill holes in the parts for their reliable connection. The holes are made at an angle of 90 degrees (straight) in the right places opposite each other. Afterwards, you need to carefully sand all the edges of the wood.

Manufacturing technology of a standard bed

Making a solid wood bed with your own hands is carried out in several successive steps:

- Preparation of necessary tools and materials.

- Carrying out calculations of the quantity of required consumables and their sizes.

- Pre-treatment of lumber.

- Making the frame.

- Assembling and installing the back and legs.

The final stage of work is treating the finished product with protective solutions, as well as decorating the bed.

Installation tools

To create a bed from logs, you will need the following tools:

- Roulette;

- Pencil;

- Construction corner;

- Level;

- Screwdriver;

- Axe;

- Plane;

- Bit;

- Grinder machine. The tool can be replaced with sandpaper of various grain sizes;

- Chisel;

- Mallet;

- tongue and groove;

- Hex key;

- Jigsaw;

- Electric drill.

Also, to work with boards you will need a hacksaw.

Calculations

To calculate the required amount of consumables, as well as the dimensions of lumber, it is necessary to draw up a drawing of the future structure. In this case, a ready-made detailed bed diagram can be used. Using it, the parameters of the product can be easily changed proportionally, thus achieving the required dimensions of the bed.

The diagram must indicate not only the dimensions of the future bed made of rounded or chopped logs, but also the attachment points of the combined elements. For complex structures, it is recommended to create drawings of the future product in different projections.

To calculate the dimensions of the bed, you can focus on the dimensions of the existing mattress. It should be taken into account that a comfortable sleeping place is one that fully accommodates the width of a person with his hands clasped in the abdominal area, and at the same time there is a margin of 20-25 cm from the elbows to the edge of the bed or sleeping place.

Material pre-treatment

Before starting work on creating a bed from chopped solid wood, the lumber must be additionally processed. Pre-finishing of the material consists of the following procedures:

- When purchasing solid logs, the bark must be removed from the lumber. This is done using a mallet and chisel or an ax. The bark can be left only in cases where it shows no signs of damage. Such logs cannot be sanded, but are only thoroughly impregnated with stain in 3-4 layers and covered with varnish. However, the use of beds made from bark logs often results in injuries. Therefore, it is still better to remove the top layer of wood.

- Sand the logs using medium-grit sandpaper. In this way, the top layer of wood is removed, renewing it after storage in warehouses. This stage also allows you to further smooth out the unevenness of the lumber and prepare the wood for deep impregnation.

- Impregnation of lumber with stain. When using the solution, not only the wood is painted in the desired shade, but also its additional disinfection.

Both rounded and chopped logs can be used to make a bed. Boards are used as additional lumber when creating beds from solid wood.

At the end of the preparatory stage, the logs are trimmed to the required dimensions. If you plan to make a massive bed from beams, semicircular cuts are made at the ends of the logs, allowing the rounded elements to be tightly placed on top of each other.

Frame making

When creating the frame of a classic standard bed 2x1.6 m from solid wood, you will need logs 2.2-2.4 m long, with a trunk diameter of at least 20 cm. You will also need boards 10 cm wide and 2.5-cm thick. 3 cm. The boards must be cut to a length of 1.6 m. They will be needed to create support for the mattress.

To install a support under the frame, you will need beams that will be attached along the inner perimeter of the frame, and one supporting central board.

The assembly of the frame from the beams occurs in the following sequence:

- On a hard surface, 4 logs are laid out in the shape of a rectangle of a suitable size, 2 of which have cuts. The elements are connected to each other with dowels or self-tapping screws.

- Along the inner perimeter of the logs, at the same level in the middle, a support beam is fixed using self-tapping screws.

- In the middle of the frame, at the same level, parallel to the side logs, a support board is fixed.

- Perpendicular to the sidewalls, boards are laid on the supports, which will serve as lamellas. They are fixed to the supports using self-tapping screws.

The optimal distance between the lamella boards is 4 cm. Instead of boards, you can also use a solid sheet of plywood. However, in this case the structure will be much weaker.

Attaching the back and legs

The backs and legs can be attached to a bed made of logs as separate elements, or built onto a frame. To make the backs and legs separately, a pair of logs are placed vertically at a distance of 1.6 m from each other. From above and 10-20 cm from the floor they are connected to each other perpendicularly by beams or logs. The elements are fixed using self-tapping screws.

For greater structural strength, the perpendicular elements of the backrest can be additionally equipped with stiffening ribs, in the form of thin beams or rounded logs. The second headboard is made using the same principle. If desired, it can be built of the same or less height. The backs with legs are attached to the frame using self-tapping screws in several places.

When adding the back and legs to the bed body, 2-4 logs are used as the lower support and 1-3 elements for constructing the frame. To extend the legs, 2 logs are connected using dowels. The bed frame is turned upside down and connected logs are fixed along its edges. After this, the structure is turned over to its normal position. At the same time, the legs extended along the edges should look like a continuation of the frame.

The back is made according to the same principle. Holes for dowels are made in the logs in the legs and at the head, and additional logs are fixed on top of them. For strength, such connections are additionally fixed with wood glue, which fills all the seams of the structure.

After assembly, the structure must stand until the glue completely hardens. Only after this can you begin the final finishing of the bed.

The final stage

After assembling the entire structure, the logs must be sanded with medium or fine-grained sandpaper. A grinder with an abrasive wheel of 140-220 microns is also suitable for this work. After processing, the wood is impregnated with a colorless or tinted stain. When it dries, the product is coated with varnish.

You can add shine to your bed in another way. The wood is coated with teak oil in several layers, and then treated with furniture wax and carefully rubbed with a leather grinding wheel. With this treatment, the tactile sensations when touching the bed will be much more pleasant.

Since this is furniture made from waste, for obvious reasons, the most painstaking work is considered to be the process of selecting the material, which will need to be combined not only in size, but also in color, as well as surface texture. Also, in the process of assembling log furniture with your own hands, quite a lot of time is spent on performing operations to connect parts (structural elements). You will learn more about the production process using the example of making the back of a homemade bed from logs.

Tools

Before carrying out the main work, it is necessary to prepare the following list of tools and equipment:

- Special impregnation for wood improves the appearance of the material and protects its surface from the appearance of fungus and mold. This is especially true if the table will be used outside in the garden. There is no point in saving on the solution; it is better to take it with a reserve.

- A hacksaw with fine teeth allows for accurate cuts of workpieces.

- An ax and a chisel with a hammer are used for removing bark from logs and some other work (grinding grooves and finishing small recesses).

- A chainsaw is considered one of the main tools when working with wood. With its help, you can cut logs both longitudinally and transversely.

- A screwdriver allows you to carry out work far from a power source.

Additional consumables you will need are self-tapping screws for fastening the parts into a single structure and transparent varnish to create a protective layer on the surface of the furniture.

Assembly

Step-by-step instructions for assembling a garden table are as follows:

- Marking lines are applied on the log and sawed with a chainsaw (when making parts for the table top, it is better to use the services of sawmill workers).

- The parts are cleared of bark using a sharp ax or a chisel and hammer.

- Clean the surfaces with a grinding machine.

- The parts are assembled into a single structure.

- Self-tapping screws are used to connect products; they are screwed into the workpieces using a screwdriver.

After making the frame of the stand, they begin to secure the table top.

Fastening the table top

In practice, there are two options for securing the table top. In small-sized furniture with minimal load on the upper part, the frame is covered with a sheet of chipboard and the element is secured with self-tapping screws. The tabletop is covered with self-adhesive paper. The lid fastening option is suitable for furniture with top dimensions of no more than 1 x 1 meter.

Installation

Assembling a table, both from rounded logs and from regular ones, primarily depends on what kind of furniture you plan to make. But, in any case, there are several main points that are the same for both complex designs and very basic simple tables.

- Drilling holes for reinforcing bars - in the log that serves as the basis for future furniture, that is, in the lowest one, the holes should not be through. A depth of half the thickness of the part will be sufficient, but in all the following elements they must be through.

- All holes should be 30 cm from each other, this is the most optimal distance that will ensure the strength of the entire structure.

- All drilled holes must be tightly filled with epoxy glue so that the rods do not dangle in them.

- The places where the parts are attached to each other should be well aligned and not too deep, ideally within 5-6 cm, this will prevent possible cracks during further use of the furniture.

Labor and cost

Preparing wood, sawing logs, making grooves and other operations is a rather complex process that requires maximum care and experience from the performer. For professionals, it will take at least 2 hours to complete all operations, for inexperienced users – much more.

The cost of furniture will depend on the type of wood (if the material needs to be purchased) and the price of consumables. For example, one self-tapping screw costs at least 5 rubles, plus additional funds for protective compounds: the price of 200 milliliters of varnish is about 200 rubles, a can of protective impregnation will cost at least 600 rubles.

Features of operation

A table made of wood can be destroyed due to moisture and direct solar radiation.

To increase the service life of a log structure, compliance with the following rules:

- do not place hot dishes on the countertop;

- constantly clean the table from dirt;

- monitor the condition of the varnished coating and periodically update it;

- install furniture in a gazebo or under a canopy.

If the table is placed in the garden, before the onset of winter you need to bring it indoors, first cleaning it from dust and dirt. The storage room must be dry and well ventilated.

Nowadays, furniture manufacturers use a fairly wide range of different materials, which significantly expands the choice of furniture designs. Glass, plastic, and metal furniture for residential premises are winning the love of consumers. But there is still a high demand for naturalness, environmental friendliness and naturalness, that is, for wooden interior items. This is exactly what log furniture is, which has been very popular lately.

From design to execution

Simple design - uncomplicated execution.

Let's start with the good news. You don’t particularly need drawings of log tables; the reason for this non-trivial approach to furniture construction lies precisely in the material. The instructions are very simple.

Logs can be used:

- For table legs. You can easily connect them together by placing them at the corners of the perimeter of a box made of boards. But more on that later.

- For the manufacture of side racks. The technology used here is to set logs to build walls. Often, in this way, combined tables and benches are prepared from logs.

- For forming table tops. This is a whole layer of material that involves the use of various techniques and methods, fastening methods and much more.

But for now, let’s look at the above; all other methods of use depend only on your imagination.

The simpler the more economical

The photo shows a vivid example of the skillful use of wood

Let's look at the simplest table that even a schoolchild can make with a saw, hammer and nails on hand. This is an option in which logs are used as legs.

To make it you will need scraps - in the literal sense of the word.

- First of all, we prepare the wooden perimeter. For this purpose, you need to connect four boards. As a result of this articulation, a rectangular structure is formed. There are many options for attaching boards. If you want, connect them using screws or nails, if you want, make a tenon connection, or if you want, use metal corners;

- Then fix four one-size logs in the corners of the formed perimeter.

Fixing logs is possible in several ways:

- The first and easiest is to nail or fix with self-tapping screws;

- The second is to make recesses in the wood so that the log is inserted flush into the corner, forming a single ensemble. This technique is more complex, as it requires either skill or special equipment.

- The final stage is installing the countertop. Quality: MDF, chipboard, OSB. The tabletop can be assembled from scraps of boards that were used for sheathing. A tabletop can even be made from logs if you cut them into at least two parts on a circular saw.

Advice! It is clear that such a table has a pronounced street character, so it is better to replace the tiled material with a stacked table top made of boards. And don’t forget to cover the boards with an antiseptic. And ideally with stain and varnish.

Table like a log house

A typesetting table made from rounded logs has recently become very popular. At the same time, the technology for its manufacture is no different from building a house. The design stages are absolutely identical, except that there is no need to install insulation between the logs.

To build this structure you need:

- Decide on the type of table. Without even going into details, I would like to note that there are a lot of options for setting tables. There can be mini huts, side posts in the shape of the letter “X”, and modern assemblies with various romantic names. To move away from fantasy and tune into a more practical mood, let's approach this issue in this way:

- Do you want to build a base in the form of a mini house, where instead of entrance doors or windows you can place drawers, where you can leave small gardening or carpentry tools in the summer? Then you need to remember the technology of building a house.

Note! The joining of logs in the corners is carried out similarly to the joining of logs during the construction of a house, using the “bowl” method.

- X-shaped bases are easier to assemble, and the need for previous joining may arise once to give the structure stability;

- Various modern designs involve not only the use of logs, but also tree branches of non-standard length and diameter.

A few words about joints.

Docking logs together can be done in three ways:

- Using wooden pegs;

- Using reinforcement rods;

- Using self-tapping screws of the required length.

If everything is clear with the screws, then the pegs require some explanation. In the case of them, the bottom log is drilled halfway through, and the rest through. The rods are inserted into the holes in such a way that they slightly expand the prepared hole, the principle of a chop or a cork in a bottle.

Every owner of a country property tries to create the most comfortable living conditions on his or her plot. Many people make gazebos, create alpine slides and pave garden paths.

One of the most original solutions will be a table made of logs, because it is ideal for installation in a gazebo or any other place. Making and decorating a table from a log of wood is not difficult.

Advantages and disadvantages

Today, like centuries ago, people try to choose the most reliable, safe and beautiful furniture for their living spaces. Many new synthetic materials, decorative techniques and specific mechanisms have been invented that are used in furniture production. But natural wood is still highly valued. The most common species used to create furniture are oak, beech, walnut, birch, pine, alder, acacia, cherry, and mahogany.

Log furniture is considered an elite purchase because it has a large number of positive qualities:

- high aesthetics - wooden surfaces have a luxurious appearance, unique texture and pattern. With their help, designers create truly “royal” interiors in ordinary city apartments and country houses. Wood goes well with many other materials: glass, metal, stone. We also note that the color schemes of natural wood are very diverse, which allows you to choose an option for any interior style;

- ecological purity, naturalness, pleasant aroma. Logs do not contain unsafe substances in their composition, therefore wooden interior items are not capable of triggering the development of allergic reactions, poisoning and other health problems in humans or pets. Species such as pine, spruce, fir have a positive effect on people with diseases of the respiratory system;

- durability - natural wood demonstrates high strength and resistance to many negative factors in the environment, therefore it lasts for a long time without changing its performance characteristics;

- easy maintenance - solid wood does not require maintenance, so it retains its original beauty for a long time. And if during operation a scratch or chip appears on the surface of the cabinet, it can be restored without much hassle;

- versatility - wooden log furniture is relevant in almost any room. The living room will look simply chic, the bedroom will be filled with coziness, and the children's room will be as safe and practical as possible with such decor.

There are also disadvantages to furniture made from timber, which is important to be aware of when choosing such interior items for a bedroom, living room or children's room. We will describe them in detail below:

- ability to crack under the influence of high humidity in the room. Even if the wood surface is well treated, it will remain sensitive to moisture. If there is no optimal humidity in the room, the furniture may dry out or swell;

- excessively high cost of wooden products. Often this fact scares off the buyer, forcing him to choose a more affordable analogue. To be fair, we add that the technology for producing interior items from timber is complex, which is why they are expensive for buyers;

- high weight - furniture made from logs is not suitable for old houses with frame floors;

- specific qualities - different types of wood evoke different tactile sensations and associative thoughts in a person. For example, the natural smell of pine can scare away one person and attract another.

Which cribs are the most popular?

The market has been filled with MDF products. This material has numerous advantages and an affordable price, so it has become the most widespread.

However, furniture is made from chipboard, veneer, plywood, wood and other materials.

The manufacturer can offer the client various options:

- unpainted;

- toned;

- smooth veneer

With its help it is possible to achieve natural shades.

Frame bed

A budget option includes a bed frame. You can install it even on an uneven surface, since the legs are height adjustable.

With lifting mechanism

- This design is convenient to install in a narrow bedroom, as it provides unobstructed access to the laundry compartment.

- The lifting mechanism has a smooth motion, thanks to which you do not have to apply much physical force when opening it.

- This bed can be called multifunctional and comfortable.

- Some parents like a loft bed, which can be used to organize a workspace for the child.

Many models are produced with desks and sports equipment. What kind of bed do you need?

Double from one and a half meters or more

Despite certain standards, the consumer can choose the width of the bed, which depends on age, comfortable sleeping position and even climate, because the hotter the region, the wider the crib should be.

Almost all modern furniture factories make beds to individual customer orders. In this case, not only the size is taken into account, but it can also create a unique design.

For such cribs it is easy to choose a furniture set of any format, size, design and other design features, including luxurious double beds

Double models made of solid wood can not be purchased in every furniture showroom.

In addition, furniture stores often offer a very modest range of these products.

To provide the buyer with a wide selection of double beds, it is necessary to use large retail areas. And not every salon can afford this, so more and more often double beds are purchased on the Internet - in virtual furniture showrooms.

Made from solid wood

A double bed made of solid wood is used in furniture production and is especially popular among demanding consumers.

Beds made from timber and boards look especially beautiful in an eco- or ethno-style interior, and will also be an indispensable attribute in a country house or dacha.

From logs

Unfortunately, the classic design does not combine with such a natural material as a log and is unlikely to be appropriate in a traditional room.

If the user likes to experiment and mix styles, then log loungers can be combined with glass and forged elements.

Made from MDF, fiberboard, chipboard

Bedroom furniture made from MDF, fiberboard or chipboard is the most common option among other more reliable materials.

Unlike the above products, such models are inferior in reliability, but are much cheaper.

Moreover, a stock made from this material quickly becomes loose, creaks, and very quickly becomes unusable. But if this furniture is purchased for a short period of time or is used very rarely, this economical option is the ideal solution.

Transformable bed

In addition to common classic designs, thanks to bold design ideas, a double bed has turned into a multifunctional piece of furniture that not only serves as a convenient and comfortable place for a good rest, but also serves as a spacious wardrobe or can easily be converted into an ordinary chest of drawers or wardrobe.

A built-in transformable bed is an ideal solution for small spaces and studio apartments.

With a slight movement of the hand, this furniture turns into a compact bookcase or home bar. It takes up very little space and is a kind of know-how in the production of original furniture.

Podium bed

Podium beds, unlike transforming and traditional models, take up a lot of space in the bedroom. But unlike their furniture relatives, they are considered a practical and convenient option, since thanks to the spacious niche they can solve the problem of storing things.

A log bed made with your own hands is not only an affordable option for bedroom equipment, but also a very stylish piece of furniture. But in order to create a comfortable and reliable bed from logs or boards, you must strictly follow the technology of its manufacture and prepare all the necessary tools in advance. It is important to choose the right not only the size of the materials, but also the type of wood.

The design of a wooden bed can be created in various styles:

- Classical. The bed stands on legs and has a rectangular shape. The design includes backrests of various sizes. The product can be supplemented with columns of various configurations and heights.

- Empire style The product has a rectangular shape and low legs. A large and angular headboard is present at the head of the bed.

- Baroque. The bed has massive dimensions and many volumetric carved elements. The back of the headboard is large in size. The backrest in the legs is thin and rarely extends beyond the mattress. But at the same time it also has many carved curls and figures.

- Ethnic or oriental. The bed frame is placed on a wide podium. There are no legs or decorative elements. The design has clear rectangular shapes.

- Rustic. The beds are made from non-rounded whole trunks and branches that have undergone minimal processing. Some bed models can even be created with wood without the bark or knots removed. In most cases, products are equipped with posts and cannot be painted.

- Colonial. The design has massive legs and is often equipped with high posts for canopies. The backs are distinguished by their massiveness and the presence of large volumetric decorative elements.

- Minimalism. This type of structure may not have legs or backs. The bed has a low height and consists solely of a frame.

There are also many bed designs created by combining different styles. At the same time, the simplest designs to implement are beds made of logs in minimalist, classic and rustic styles. However, given the importance of the presence of legs in the structure to ensure air circulation, as well as the need for pleasant tactile sensations, the best option for making your own would be a classic-style bed.

Types of products

Furniture made from logs is very relevant for many premises. In its manufacture, different types of wood are used, so the operational parameters may vary.

Conventionally, experts divide all wood species used in the production of log interior items into two types:

- made of hard wood: maple, oak, ash, walnut. Such species are relevant for the manufacture of furniture that experiences the highest load during operation. For example, a bed frame, a dining table top;

- from soft wood: poplar, willow, pine, spruce, chestnut. These types of wood are used for the manufacture of decorative elements when decorating log furniture. For example, facades, carved decorations.

We also note that furniture made from solid logs will be more reliable, durable, and more expensive than options made from laminated veneer lumber.

The appearance of log furniture may also be different, which is a consequence of the use of different compositions to give the item high resistance to impact:

- painted - to decorate wooden furniture, various types of coloring compounds are used, which can completely cover the natural pattern of the wood or slightly shade it. This ultimately determines the external aesthetics of the item;

- varnished (matte, glossy). Varnish with a gloss effect allows you to add clarity and brightness to the wood grain. Such surfaces are perfect for classic interiors. And matte wax gives the surface a special charm, relevant for country, Provence and other areas of residential decor.

Where is it most often used?

The use of rounded logs is relevant in many stylistic areas of residential decor, as it can be successfully combined with other materials, with many color shades in the decor of walls, ceilings, and floors. But most often such decorative items can be found in rooms with decor in the following styles.

| Room design direction | Characteristic |

| Country | Country style is distinguished by the naturalness of its materials, so log tables, chairs, beds, and cabinets will fit perfectly into rooms of this style. |

| Provence | Provence requires laconic forms, simplicity of color shades and naturalness of the materials used, which, by the way, corresponds to furniture made of rounded timber. |

| Loft | The loft style is unusual and simple, practical and resists everything overly pompous and expensive. However, it is log furniture that is successfully combined with glass, brick, and plaster, which are so often used in such interiors. |

| Classic | When properly processed, natural wood furniture acquires a strict, conservative look, which is very important for classic living rooms and bedrooms. |

No less relevant is log furniture for a garden house, a gazebo on a summer cottage or a park. But you shouldn’t leave it in the open air for a long time, as precipitation will negatively affect the quality of the surface.

You can complement the beauty of timber furniture with the help of decorative elements made of natural rattan, glass or metal, leather.

Advantages and disadvantages

A log table fits perfectly into the interior of a summer cottage. Its massiveness creates an atmosphere of coziness and comfort in the yard or garden. Log tables have many advantages:

- Strength. The product made from logs is quite strong. Such tables can withstand various loads well and are much more practical than wooden furniture made from boards.

- Aesthetic appearance. Log tables are often installed in gazebos in summer cottages. They fit perfectly into the interior of the surrounding nature. Log tables can be combined with many materials - stone, glass or metal.

- Availability of material. You can make a table from logs left over from construction. To make it, you can also use fallen trees near the site or in the forest.

- Ease of manufacture. The log table has a simple structure. By using your imagination and deciding on the dimensions, you can build any structure yourself. To do this, you just need to be able to use woodworking tools and draw up the correct drawing.

- Environmentally friendly material. Logs are a natural material that does not contain harmful substances. The use of log tables does not cause an allergic reaction and is completely safe for humans.

- Long service life. If properly cared for, log tables can last for quite a long time.

The disadvantages include the heavy weight of the product. Also, without proper protective coating, logs can crack, dry out or swell when exposed to moisture and direct sunlight.

A table made of logs is not only convenient to use, but also perfect for decorating a garden interior. This type of furniture, made with your own hands, will decorate your summer cottage for many years.

Nuances of choice

Log furniture has a number of advantages. However, this rule applies only to those pieces of furniture that are made strictly according to technology using high-quality fittings and fasteners. Saving on components or protective coatings for logs can have a detrimental effect on the durability of structures and will reduce their resistance to the negative influence of external factors. Therefore, you need to choose such interior items carefully, without haste, weighing all the pros and cons.

Let us describe the main factors that cannot be ignored when choosing wooden furniture:

- cost - the process of creating furniture from logs is quite complex, painstaking and cannot be rushed. Only if this condition is met can it be said that the log bed will serve for several decades in a row. That is why interior items of this kind cannot be cheap. A low price should alert the buyer, force him to carefully inspect the design for defects, read the accompanying documentation for the product (quality certificate, passport, assembly and maintenance instructions);

- sizes - log interior items often have impressive dimensions, so they should not be selected for narrow spaces with poor lighting. In small rooms they will look overly bulky and will weigh down the space. And for large spaces, such furniture is simply a godsend;

- surface aesthetics - the logs used in the manufacturing process of the furniture structure should not contain knots, chips of the interlayer in the wood mass, and the annual rings should be located as close as possible. These factors will indicate the high quality of the material used. If the bed does have such shortcomings, its price should be significantly reduced.

Taking these factors into account, you can choose successful models of tables, chairs, beds or cabinets made from rounded logs and profiled logs for your home or cottage.

§ How is wood selected? Important point!

Trees exist wherever a person lives, unless, of course, it is a desert or steppe. There will always be some companies that care for plantings, energy companies, farms, construction sites where they clear areas for plantings, and, of course, landfills. Also, do not forget about the forest washed ashore. To ensure that log furniture is of high quality and durable, you should carefully choose the wood. You should not take timber with traces of damage from woodworms; all bark should be peeled off on site, since various insects can live in it, the appearance of which in the workshop is undesirable.

After selecting the base material, manufacturing of structural parts, for example, log

bed, takes only a couple of hours. First you need to cut out the posts, horizontal frames, and the balusters of the bed headboards. After this, use a metal brush to remove all dirt and roughness from the surface of the workpieces. Then the balusters and trims are equipped with tenons cut using special equipment. The electric planer must be attached to a loop so that it hangs over the part itself. The part is clamped on the lathe bed. The length of the tenons of the straps should be 5 cm, and the tenons of the balusters should be 4 cm.

After this, using a two-handed electric drill with a Forstner drill, you need to drill sockets for the tenons in the legs and straps. The peculiarity of this operation is that, unlike bars and boards, which have certain standard sizes, all logs are different and the nests in them must be selected one at a time, carefully adjusting them to the mating parts each time.

Final assembly of the product. Dry assembly, gluing of log furniture

, as well as the installation of clamps, are similar to normal carpentry operations. There is one caveat here though. After coating the nests with catalyzed gap-filling glue (casein glue with transverse intermolecular bonds is mainly used) and assembling the structure, take the backrest by the horizontal straps and hit the backrest firmly with the leg on the floor. Only after this operation can we consider that the spikes are firmly seated and grasp the clamps.

Particular attention should be paid to the finishing of log furniture. Wood is sanded with 80 micrometer abrasive, cedar is sometimes sanded with 120 micrometer abrasive, and maple butcher blocks, as well as sawn beams from recycled materials, are sanded with 220 micrometer sand. The wood is not stained and therefore retains its natural warmth and reliability. For even greater durability of furniture made from waste

, the logs are covered with several (mostly two) layers of polyurethane. On chairs and tables made from sawn beams, as well as maple butcher blocks, a couple of layers of teak oil are applied with intermediate sanding of each layer, briuox wax (paraffin) and then rubbed with a leather wheel to a perfect shine.

There are enough companies and individual craftsmen on the market who manufacture such furniture. It is environmentally friendly, practical and very beautiful, looks great in any interior. You can buy it from a ready-made sample or order it according to your own preference. Approximate prices: chairs and armchairs made of logs - from $100, cabinets and chests of drawers - from $110, log beds - from $280, tables with benches - from $220. The cost depends on the type of wood used, its quality, the amount of materials consumed, the amount of work and the complexity of the design. Therefore, the price may vary greatly among different manufacturers.

In addition to furniture, you can also make your own house from waste. The trend towards maximum use of wood waste is especially relevant in our time. After all, this concerns natural materials and natural resources that take a long time to reproduce.

Advantages of furniture made from logs

To make country furniture from wood, you need skills in working with power tools, desire and imagination. The material can be found everywhere, it can be an old tree on the site, or in a forest area near the house.

A good addition to a massive log will be unusually shaped driftwood; you can look for them on the shores of reservoirs. They will enliven the furniture composition and add a touch of originality.

The advantages of wooden furniture include:

- It can be made from available materials, low cost.

- The aesthetic appeal of wood, the originality of garden sets.

- Durability of log furniture, provided the wood is properly processed.

- Fits naturally into the natural landscape.

Depending on the source material and its size, different options for garden furniture are obtained.

Benches made of wood and brick

Photo - a reliable and stable bench, unfortunately not mobile

The brick will act as legs, and the wooden board as the seat. The bricks are laid out in seven or eight levels, depending on the desired height of the bench.

The width of the foundation below the seat is two or three bricks, the width of the armrest above the seat is one or two bricks. The bricks do not need to be held together with cement, then the bench can be disassembled and rearranged at any time, but for strength it is better to do this. The seat itself can also be attached using cement. The finished design is shown in the photo.

DIY garden furniture made from logs

Wood is a unique natural material. After special processing, its beautiful texture appears.

Sets of log tables and benches: 15 photos

They use not only logs and driftwood, but also saw cuts. The blocks are used to make paths in the garden, table tops, and bench seats. They are filled with transparent epoxy resin. Such items are exclusive and durable.

There are three rules for processing logs:

- The bark, especially from old trees, is removed using a metal scraper or spatula. Under the layer of bark there are nests of insects and pests. Once the bark is scraped off, the beautiful texture of the material is revealed.

- The tree needs to be treated against moisture and pests. Impregnations, stains, and varnishes serve as additional protection and help the texture of the material to appear and emphasize the natural pattern.

- Furniture surfaces that come into contact with the body must be sanded to avoid splinters.

You need to be creative when making furniture. Nature itself is a good master.

Log furniture options:

- deliberately rough sets;

- combined: log with snags or saw cuts;

- furniture made from processed, sawn tree trunks.

A separate set is unique, since each tree in nature is unique, different in texture, shape, size.

Making a bench

They are installed in the most picturesque corners of the garden. The simplest option for a bench for a summer cottage is to cut a solid trunk in half with a saw and install it on a base of stumps.

Bench options: 9 photos

Assembly instructions

For a strong connection between the seat and the supports, tongue-and-groove joints are cut into them. Additionally, you can mount a backrest from the second part of the log, securing it to thinner logs.

We recommend watching the video: how to make a bench from logs.

The combined option looks interesting. The seat is made from a cut trunk, and the back is made from treated driftwood. Installed on stumps with remains of horse taps. The bark is first removed from the wood and sanded. Treat with anti-moisture agents and allow to dry. Then they are opened with stain and moisture-resistant varnish.

The result is an expressive product that will decorate any landscape. Such objects look almost like a natural element.

It is recommended to make a base under the benches so that there is natural ventilation of the base, it will prevent rotting.

Ready-made drawings of benches

How to make a table

When designing a site, designers often use tree trunks to create furniture. They start from the source material and its size.

You will need the following tools:

- axe, scraper for removing bark;

- planer for cleaning;

- chainsaw;

- grinder or sandpaper for sanding;

- electric drill, make holes for fastenings,

- fasteners;

- chisel, they use it to hollow out a “bowl”, a groove for mounting the base.

It is necessary to follow the sequence of manufacturing and assembly.

A drawing is made before assembly.

A selection of table drawings

Making tables and benches using simple logs

Of course, not every site has a tree stump or a large log; more often, there are many small or medium-sized logs for creating furniture. Massive logs are used to make table legs; they can be dug into the ground for greater stability. It is better to nail the table top not to the legs, but to the frame encircling the legs from the outside. Drawings of a table and an original chair made of thin logs are presented in the photo below.

Photo - part of the log was used for firewood, and the back was a board

This is the simplest DIY garden furniture, which requires a long, thick log to create. We saw it crosswise, exactly in the middle.

We saw the first log formed lengthwise. You will get a back and a seat. The second log needs to be cut crosswise into two more parts, these will be the legs of the bench.

It is better to make recesses in the legs for the seat to make the structure more stable and durable. To attach the backrest, you will need two boards or two short pieces of wood. Secure it as shown in the photo.